ISUZU KB P190 2007 Workshop Repair Manual

KB P190 2007

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57177/w960_57177-0.png

ISUZU KB P190 2007 Workshop Repair Manual

Trending: service schedule, engine oil capacity, heating, ground clearance, fuel filter location, IMMOBILISER, check 4wd

Page 191 of 6020

FRAME AND BUMPER 2A-37

4 ×

××

× 2, HIGH RIDE, LWB, CREW CAB MODEL

RTW72AXF002501

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 192 of 6020

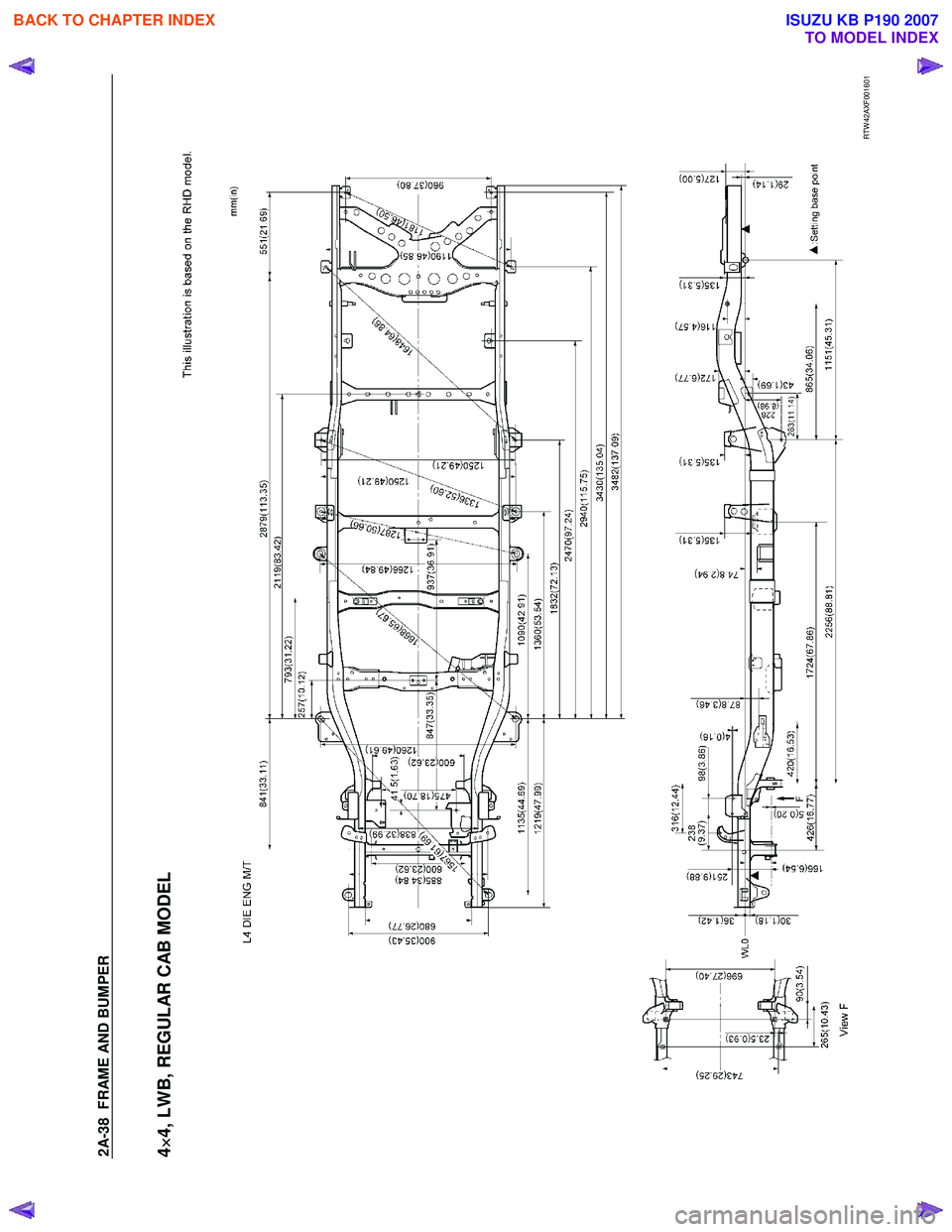

2A-38 FRAME AND BUMPER

4 ×

××

× 4, LWB, REGULAR CAB MODEL

RTW42AXF001601

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 193 of 6020

FRAME AND BUMPER 2A-39

4 ×

××

× 4, LWB, EXTEND CAB MODEL

RTW32AXF005801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 194 of 6020

2A-40 FRAME AND BUMPER

4 ×

××

× 4, LWB, CREW CAB MODEL

RTW72AXF002901

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 195 of 6020

FRAME AND BUMPER 2A-41

4

×

××

× 4, EXTRA LWB, REGULAR CAB MODEL

RTW32AXF004801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 196 of 6020

2A-42 FRAME AND BUMPER

4×

××

× 4, EXTRA LWB, EXTEND CAB MODEL

RTW72AXF003001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 197 of 6020

FRAME AND BUMPER 2A-43

4 ×

××

× 4, EXTRA LWB, CREW CAB MODEL

RTW32AXF005001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 198 of 6020

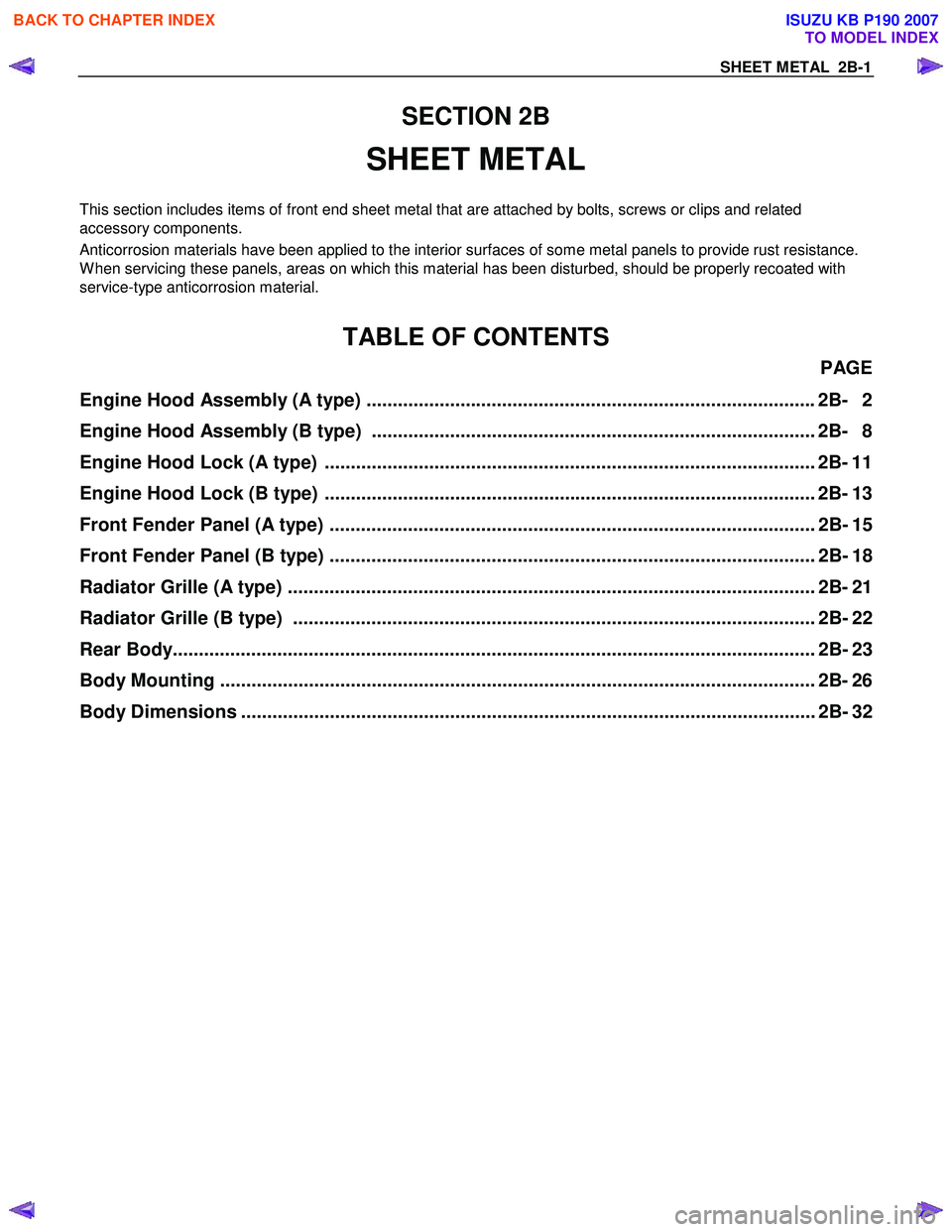

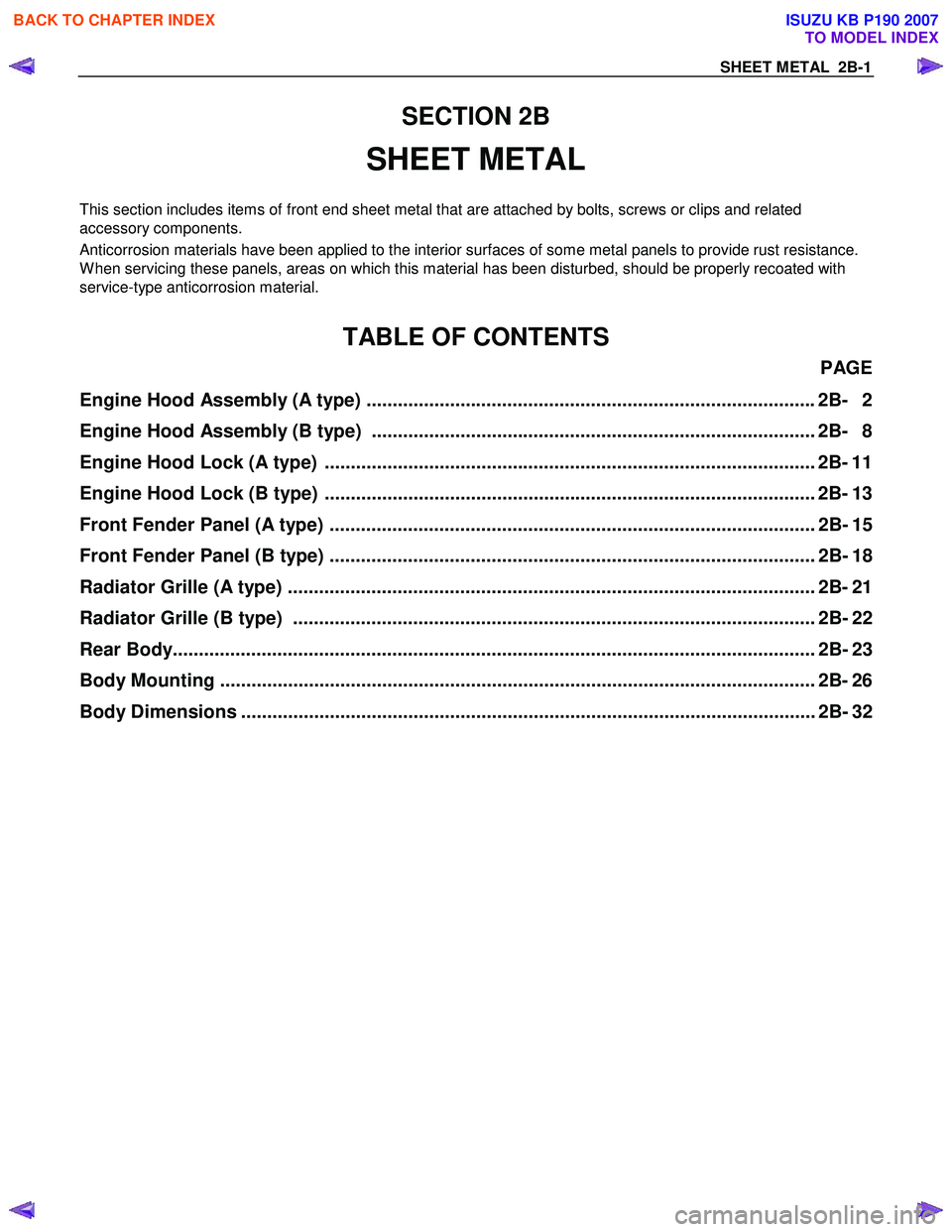

SHEET METAL 2B-1

SECTION 2B

SHEET METAL

This section includes items of front end sheet metal that are attached by bolts, screws or clips and related

accessory components.

Anticorrosion materials have been applied to the interior surfaces of some metal panels to provide rust resistance.

W hen servicing these panels, areas on which this material has been disturbed, should be properly recoated with

service-type anticorrosion material.

TABLE OF CONTENTS

PAGE

Engine Hood Assembly (A type) ...................................................................................... 2B- 2

Engine Hood Assembly (B type) ..................................................................................... 2B- 8

Engine Hood Lock (A type) .............................................................................................. 2B- 11

Engine Hood Lock (B type) .............................................................................................. 2B- 13

Front Fender Panel (A type) ............................................................................................. 2B- 15

Front Fender Panel (B type) ............................................................................................. 2B- 18

Radiator Grille (A type) ..................................................................................................... 2 B- 21

Radiator Grille (B type) .................................................................................................... 2B - 22

Rear Body...................................................................................................................... ..... 2B- 23

Body Mounting .................................................................................................................. 2B- 26

Body Dimensions .............................................................................................................. 2B - 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 199 of 6020

2B-2 SHEET METAL

ENGINE HOOD ASSEMBLY (A TYPE)

REMOVAL AND INSTALLATION

RTW 72BLF000601

Except 4JK1 (High Output) / 4JJ1 (High Output) Model

Removal Steps Installation Steps

1. W asher nozzle tube 6. Hood seal

2. Hood hinge bolt 5. Hood insulator

3. Engine hood 4. W asher nozzle

4. W asher nozzle

3. Engine hood

5. Hood insulator

2. Hood hinge bolt

6. Hood seal 1. W asher nozzle tube

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 200 of 6020

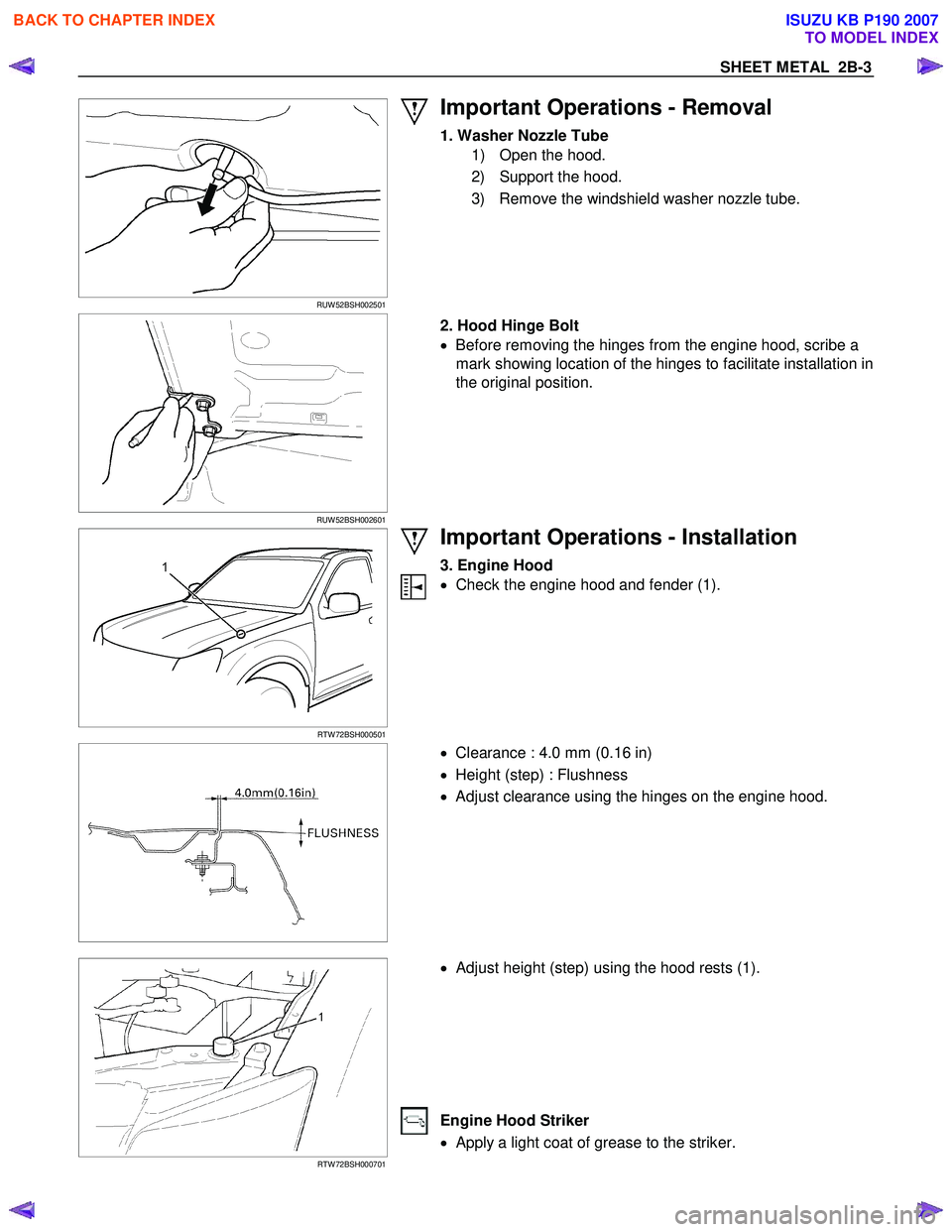

SHEET METAL 2B-3

RUW 52BSH002501

Important Operations - Removal

1. Washer Nozzle Tube

1) Open the hood.

2) Support the hood.

3) Remove the windshield washer nozzle tube.

RUW 52BSH002601

2. Hood Hinge Bolt

• Before removing the hinges from the engine hood, scribe a

mark showing location of the hinges to facilitate installation in

the original position.

RTW 72BSH000501

Important Operations - Installation

3. Engine Hood

• Check the engine hood and fender (1).

• Clearance : 4.0 mm (0.16 in)

• Height (step) : Flushness

• Adjust clearance using the hinges on the engine hood.

RTW 72BSH000701

• Adjust height (step) using the hood rests (1).

Engine Hood Striker

• Apply a light coat of grease to the striker.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Trending: transmission, wheel bolts, ground clearance, tow, fuel pressure, buttons, wheel alignment