JAGUAR X308 1998 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 251 of 2490

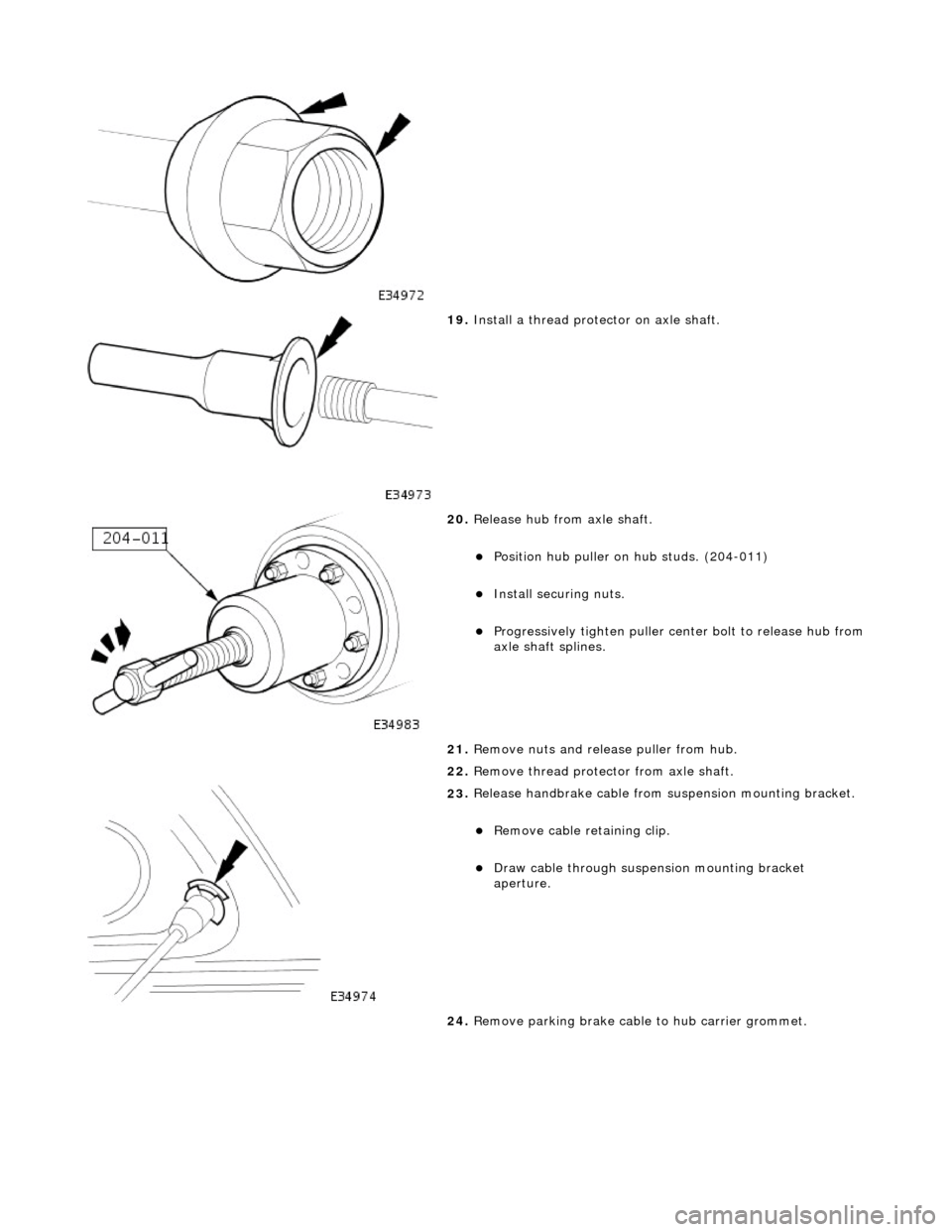

19

.

Install a thread protector on axle shaft.

20

.

Release hub from axle shaft.

Position hu

b puller on hub studs. (204-011)

Inst

all securing nuts.

Progres

sively tighten

puller center bolt to release hub from

axle shaft splines.

21. Remove nuts and release puller from hub.

22. Remove thread protec tor from axle shaft.

23

.

Release handbrake cable from suspension mounting bracket.

Remove cable reta

ining clip.

Draw c

able through suspension mounting bracket

aperture.

24. Remove parking brake cable to hub carrier grommet.

Page 252 of 2490

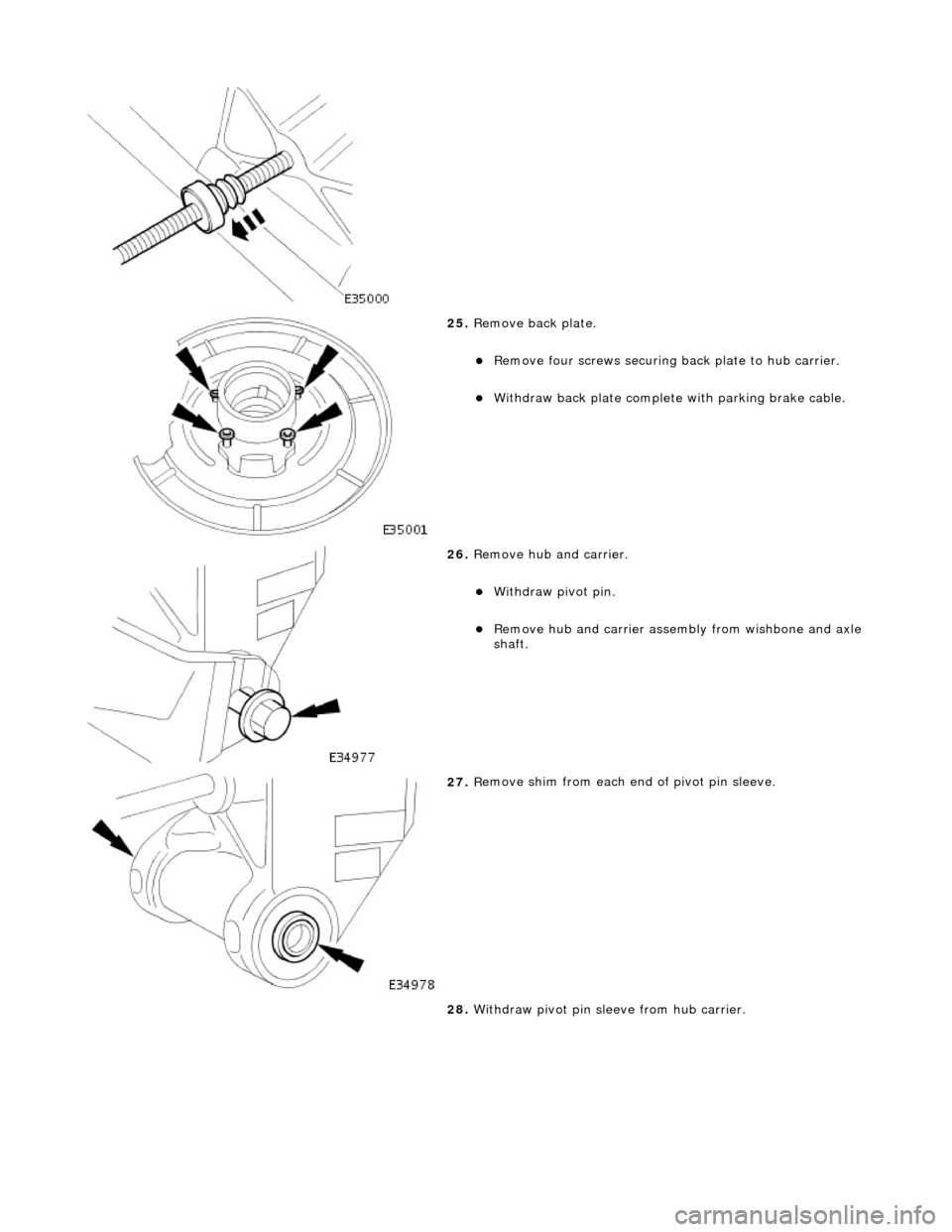

25. Remove back plate.

Re

move four screws securing

back plate to hub carrier.

Withdraw back plate

complete

with parking brake cable.

26 . Remove h

ub and carrier.

With

draw pivot pin

.

R

e

move hub and carrier assemb

ly from wishbone and axle

shaft.

27 . R

emove shim from each end of pivot pin sleeve.

28. Withdraw pivot pin sleeve from hub carrier.

Page 253 of 2490

I

nstallation

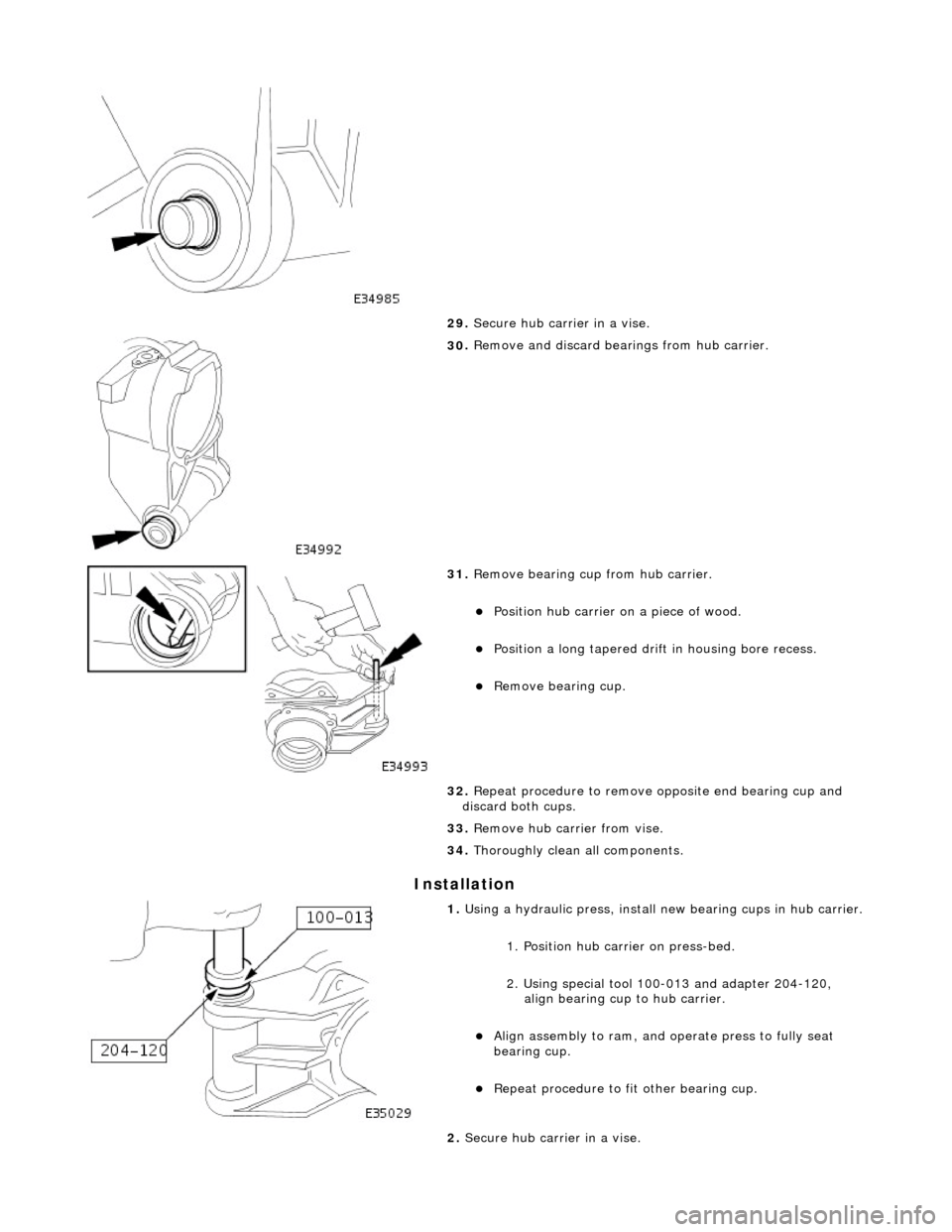

29

.

Secure hub carrier in a vise.

30

.

Remove and discard bear ings from hub carrier.

31

.

Remove bearing cup from hub carrier.

Posit

ion hub carrier on a piece of wood.

Position a lo

ng tapered drif

t in housing bore recess.

Remove bearin

g cup.

32. Repeat procedure to remove opposite end bearing cup and

discard both cups.

33. Remove hub carrier from vise.

34. Thoroughly clean all components.

1. Using a h

ydraulic press, install

new bearing cups in hub carrier.

1

. Position hub carri

er on press-bed.

2. Using special tool 100-013 and adapter 204-120, align bearing cup to hub carrier.

Al

ign assembly to ram, and

operate press to fully seat

bearing cup.

Repeat

procedure to fi

t other bearing cup.

2. Secure hub carri er in a vise.

Page 254 of 2490

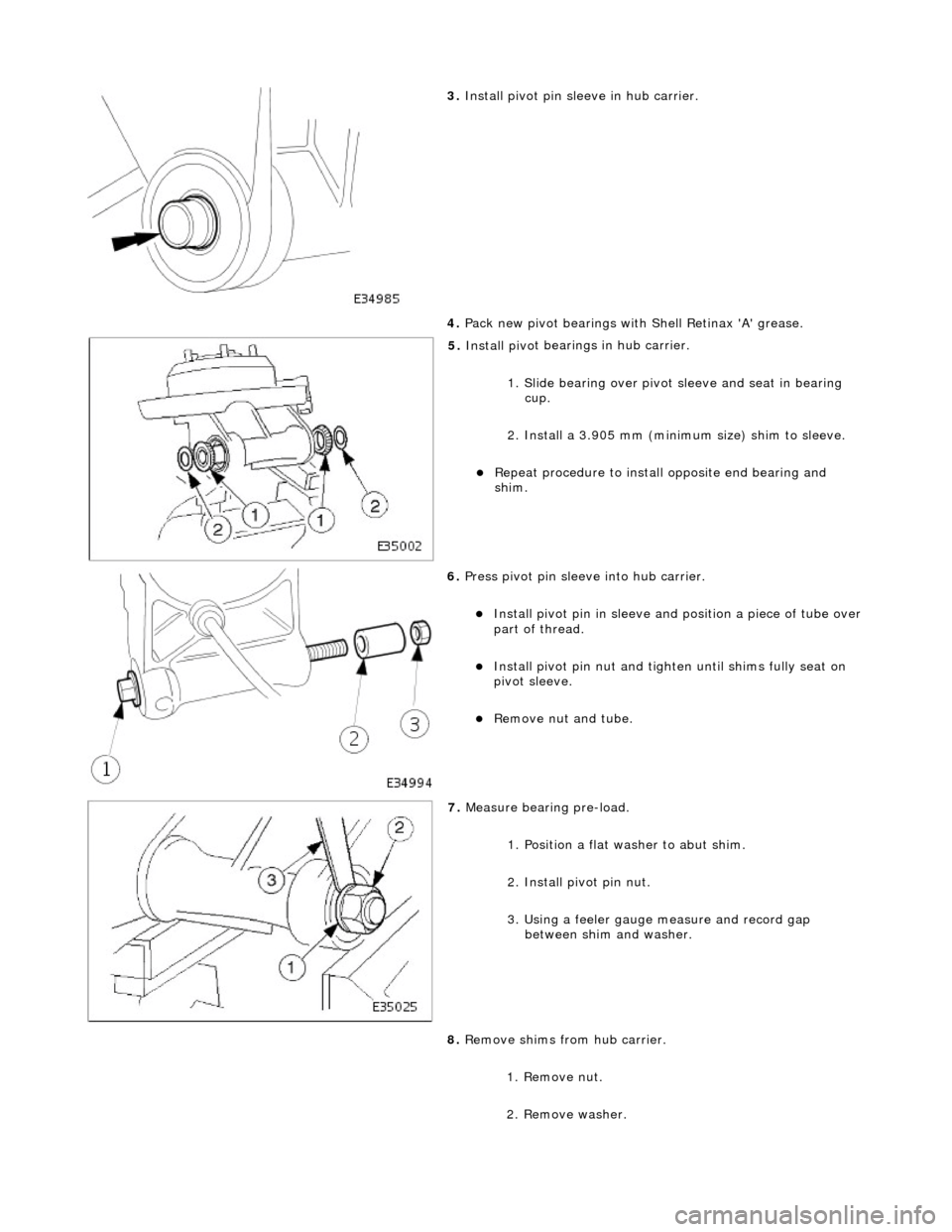

3. Install pivo

t pin sleeve in hub carrier.

4. Pack new pivot bearings with Shell Retinax 'A' grease.

5. Install piv o

t bearings in hub carrier.

1. Slide bearing over pivot sleeve and seat in bearing

cup.

2. Install a 3.905 mm (minimum size) shim to sleeve.

Repeat procedu

re to instal

l opposite end bearing and

shim.

6. Press piv o

t pin sleeve into hub carrier.

Install piv

o

t pin in sleeve and

position a piece of tube over

part of thread.

Install piv o

t pin nut and tighte

n until shims fully seat on

pivot sleeve.

Remove n u

t and tube.

7. Measure bearin g pre-load.

1. Position a flat washer to abut shim.

2. Install pivot pin nut.

3. Using a feeler gauge measure and record gap between shim and washer.

8. Remove shims from hub carrier.

1. Remove nut.

2. Remove washer.

Page 255 of 2490

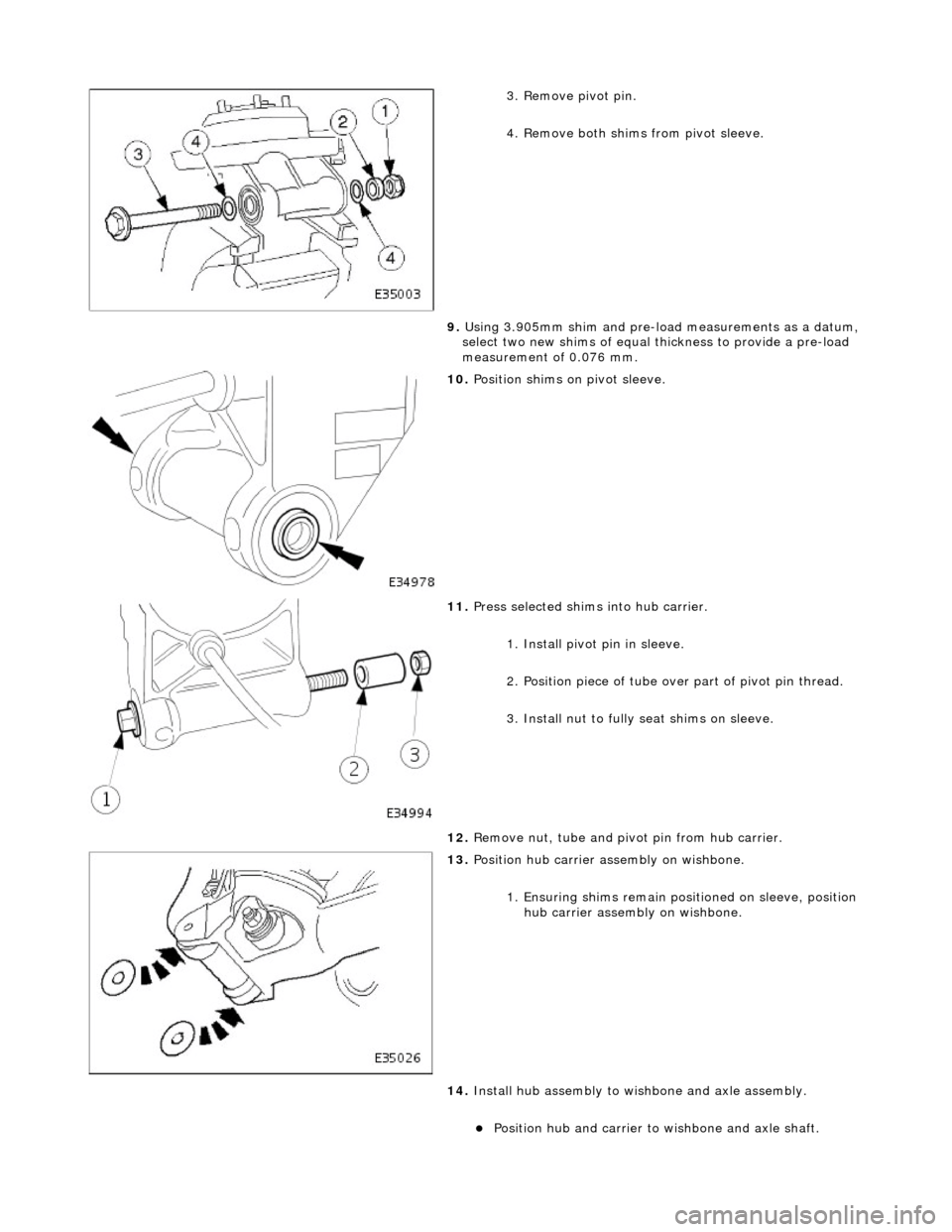

3

. Remove pivot pin.

4. Remove both shims from pivot sleeve.

9. Using 3.905mm shim and pre-load measurements as a datum,

select two new shims of equal thickness to provide a pre-load

measurement of 0.076 mm.

10

.

Position shims on pivot sleeve.

11

.

Press selected shims into hub carrier.

1. Install pivot pin in sleeve.

2. Position piece of tube ov er part of pivot pin thread.

3. Install nut to fully seat shims on sleeve.

12. Remove nut, tube and pivot pin from hub carrier.

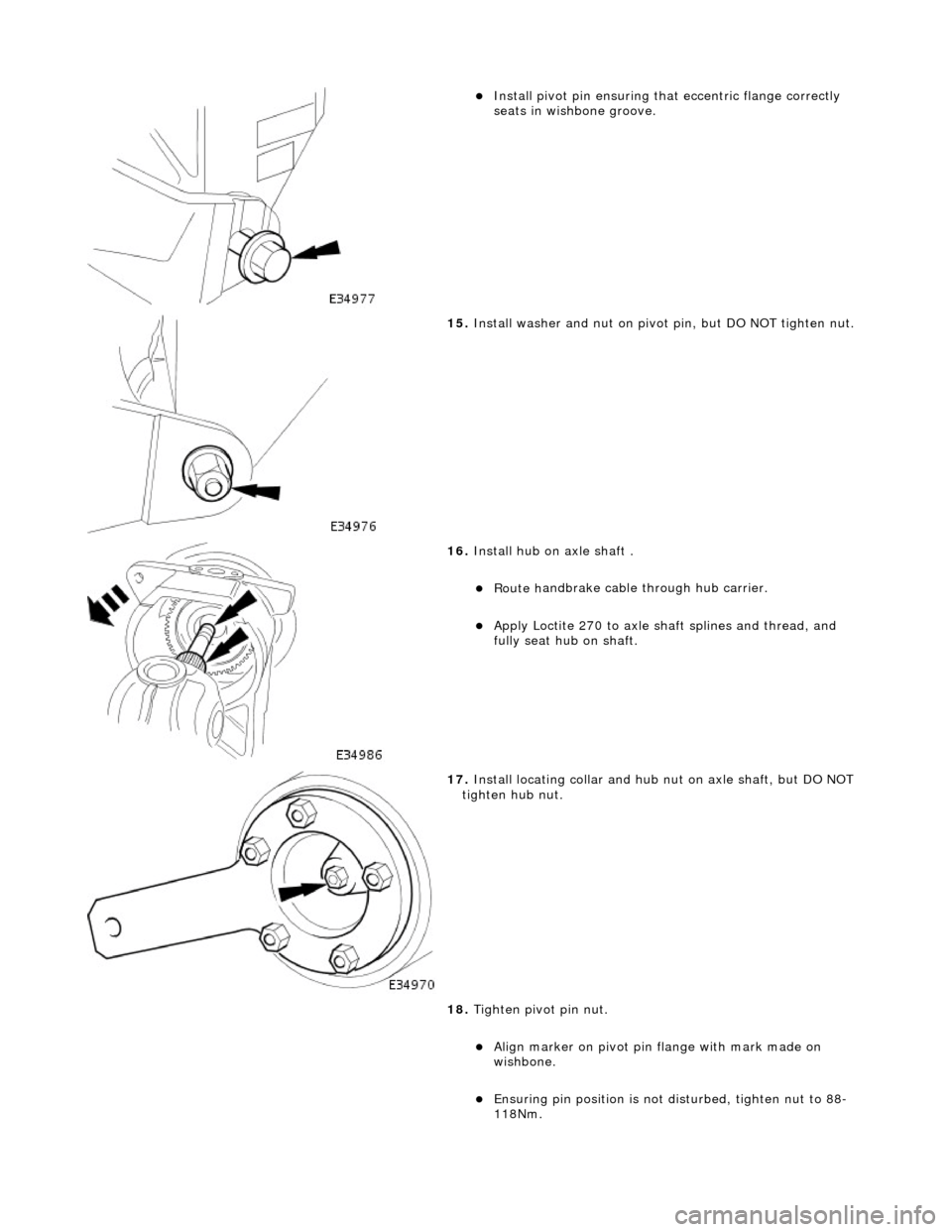

13

.

Position hub carrier as sembly on wishbone.

1. Ensuring shims remain posi tioned on sleeve, position

hub carrier assembly on wishbone.

14. Install hub assembly to wi shbone and axle assembly.

Position hu

b and carrier to wishbone and axle shaft.

Page 256 of 2490

Install pivo

t pin ensuring that

eccentric flange correctly

seats in wishbone groove.

15 . Inst

all washer and nut on pivot pin, but DO NOT tighten nut.

16 . Install hu

b on axle shaft .

Rout

e h

andbrake cable through hub carrier.

Appl

y Loct

ite 270 to axle shaft splines and thread, and

fully seat hub on shaft.

17 . Inst

all locating collar and hub nut on axle shaft, but DO NOT

tighten hub nut.

18. Tighten pivot pin nut.

Align mark

er on pivot pin flange with mark made on

wishbone.

Ensuri ng pi

n position is not

disturbed, tighten nut to 88-

118Nm.

Page 257 of 2490

19

.

Install wheel speed sensor on hub carrier.

Posit

ion sensor on hub carrier

and install and tighten bolt

to 7-10Nm.

Conne

ct wheel speed sensor harness to sensor.

20

.

Using new tie strap, secure wh eel speed sensor harness to

brake hose clip.

21. Install parking brake shoe s. Refer to 70.40.05.

22

.

Install special tool (204-195) on studs and install securing

nuts.

23. Tighten hub nut to 304-336Nm.

Page 258 of 2490

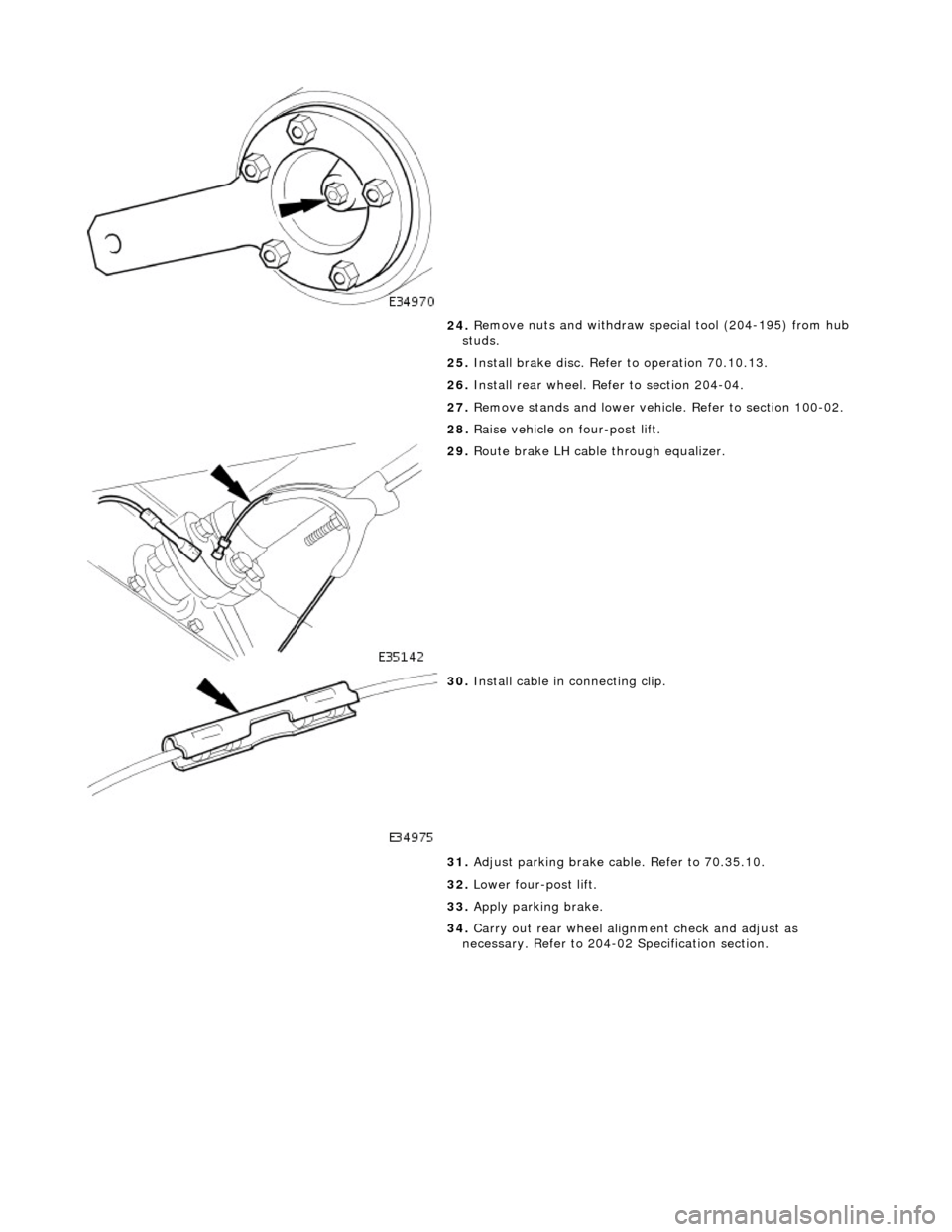

24

. R

emove nuts and withdraw special tool (204-195) from hub

studs.

25. Install brake disc. Refer to operation 70.10.13.

26. Install rear wheel. Refer to section 204-04.

27. Remove stands and lower vehicl e. Refer to section 100-02.

28. Raise vehicle on four-post lift.

29 . Rout

e brake LH cable through equalizer.

30 . Inst

all cable in connecting clip.

31. Adjust parking brake cable. Refer to 70.35.10.

32. Lower four-post lift.

33. Apply parking brake.

34. Carry out rear wheel alignm ent check and adjust as

necessary. Refer to 204-02 Specification section.

Page 259 of 2490

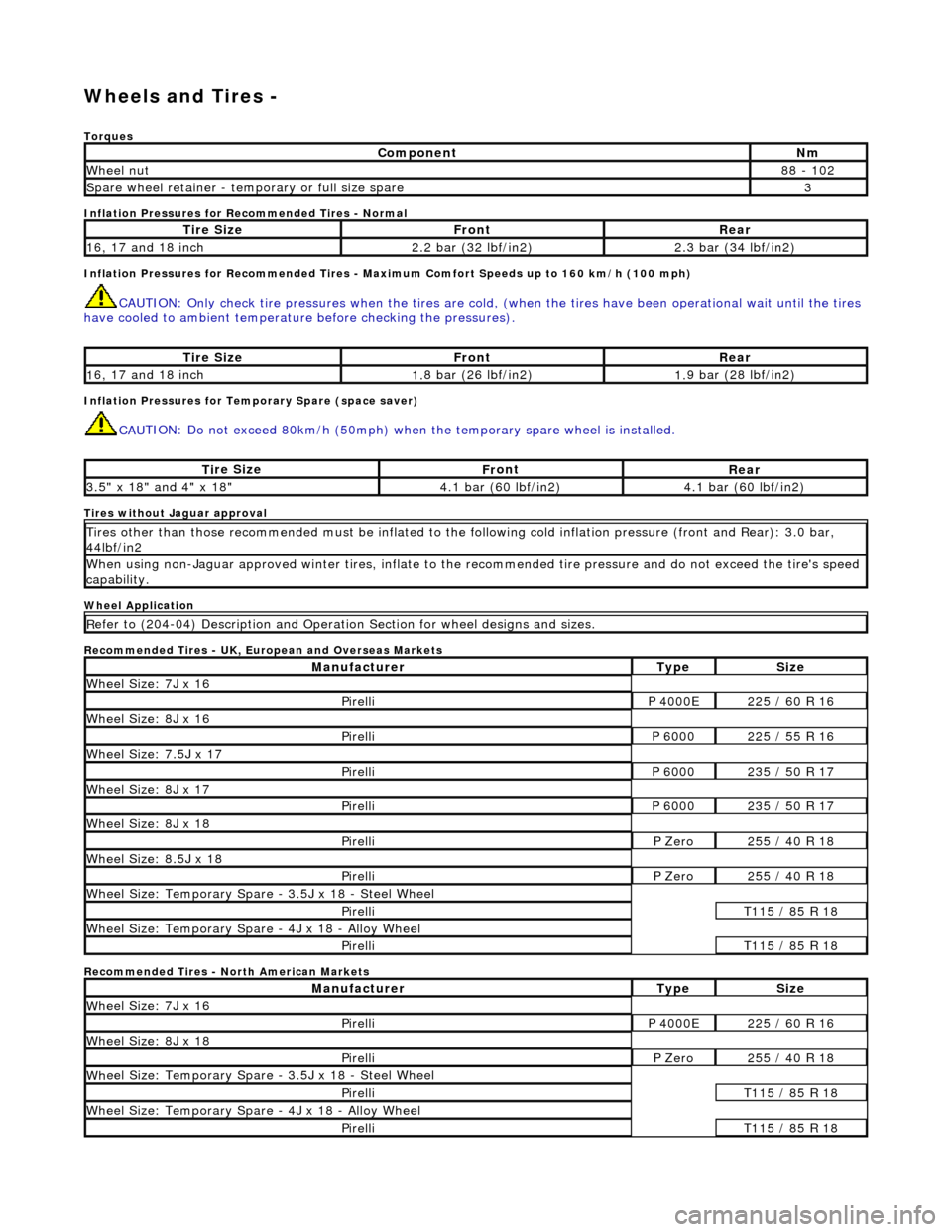

W

heels and Tires -

Torq

ues

Inflation Pressures for Recommended Tires - Normal

Inflation Pressures for Recommended Tires - Maxi mum Comfort Speeds up to 160 km/h (100 mph)

CAUTI

ON: Only check tire pressures when

the tires are cold, (when the tires have been operational wait until the tires

have cooled to ambient temperature before checking the pressures).

Inf

lation Pressures for Temporary Spare (space saver)

CAU

TION: Do not exceed 80km/h (50mph) when the temporary spare

wheel is installed.

Tires

without Jaguar approval

Wheel Application

Recommended Tires - UK, European and Overseas Markets

Recommended Tires - North American Markets

Com

ponent

Nm

Wh

eel nut

8

8 - 102

Spare wheel r

etainer - temporary or full size spare

3

Ti

re Size

Fr

ont

Rear

1

6, 17 and 18 inch

2.

2 bar (32 lbf/in2)

2.

3 bar (34 lbf/in2)

Ti

re Size

Fr

ont

Rear

1

6, 17 and 18 inch

1.

8 bar (26 lbf/in2)

1.

9 bar (28 lbf/in2)

Ti

re Size

Fr

ont

Rear

3.

5" x 18" and 4" x 18"

4.

1 bar (60 lbf/in2)

4.

1 bar (60 lbf/in2)

Ti

res other than those recommended must be inflated to the following cold

inflation pressure (front and Rear): 3.0 bar,

44lbf/in2

Wh

en using non-Jaguar approved winter ti

res, inflate to the recommended tire pressure and do not exceed the tire's speed

capability.

R

efer to (204-04) Description and Operation Section for wheel designs and sizes.

Manufact

urer

Ty

pe

Si

ze

W

heel Size: 7J x 16

Pire

lli

P 40

00E

2

25 / 60 R 16

W

heel Size: 8J x 16

Pire

lli

P 60

00

2

25 / 55 R 16

Wh

eel Size: 7.5J x 17

Pire

lli

P 60

00

2

35 / 50 R 17

W

heel Size: 8J x 17

Pire

lli

P 60

00

2

35 / 50 R 17

W

heel Size: 8J x 18

Pire

lli

P Ze

ro

2

55 / 40 R 18

Wh

eel Size: 8.5J x 18

Pire

lli

P Ze

ro

2

55 / 40 R 18

Wh

eel Size: Temporary Spare - 3.5J x 18 - Steel Wheel

Pire

lli

T1

15 / 85 R 18

W

heel Size: Temporary Spare - 4J x 18 - Alloy Wheel

Pire

lli

T1

15 / 85 R 18

Manufact

urer

Ty

pe

Si

ze

W

heel Size: 7J x 16

Pire

lli

P 40

00E

2

25 / 60 R 16

W

heel Size: 8J x 18

Pire

lli

P Ze

ro

2

55 / 40 R 18

Wh

eel Size: Temporary Spare - 3.5J x 18 - Steel Wheel

Pire

lli

T1

15 / 85 R 18

W

heel Size: Temporary Spare - 4J x 18 - Alloy Wheel

Pire

lli

T1

15 / 85 R 18

Page 260 of 2490

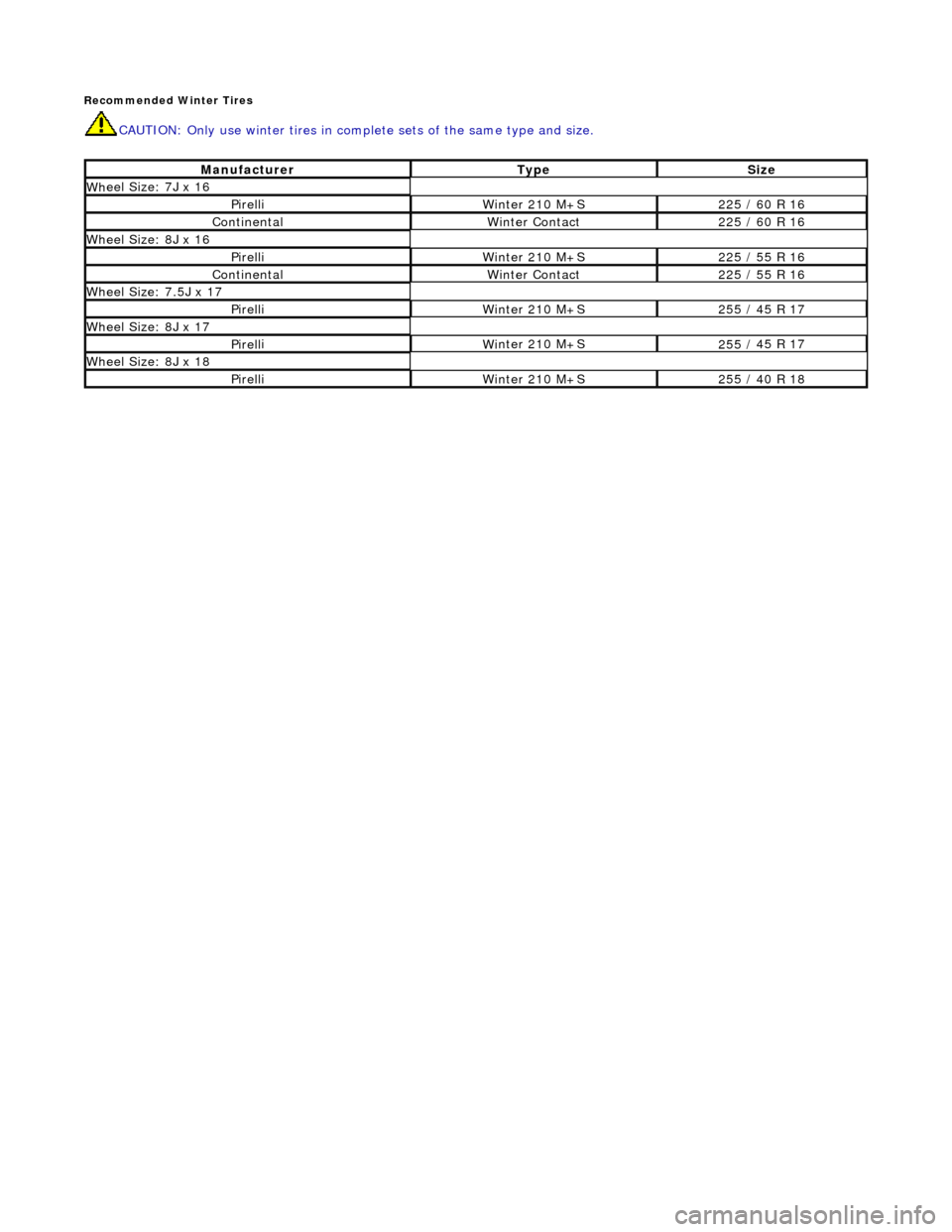

Reco

mmended Winter Tires

CAUTI

O

N: Only use winter tires in comp

lete sets of the same type and size.

Manufact urerTypeSize

Wh

eel Size: 7J x 16

Pire

ll

i

W

i

nter 210 M+S

2

25 /

60 R 16

ContinentalWint

er Cont

act

2

25 /

60 R 16

Wh

eel Size: 8J x 16

Pirell

i

Wi

nter 210 M+S

225 /

55 R 16

ContinentalWinter Cont

act

225 /

55 R 16

Whee

l Size: 7.5J x 17

Pirell

i

Wi

nter 210 M+S

255 /

45 R 17

Wh

eel Size: 8J x 17

Pire

ll

i

W

i

nter 210 M+S

2

55 /

45 R 17

W

h

eel Size: 8J x 18

Pire

ll

i

W

i

nter 210 M+S

2

55 /

40 R 18