MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: fuse diagram, mirror, fuel reserve, manual transmission, tire pressure reset, towing, power steering fluid

Page 1591 of 1865

14 MOLDING AND GARNISH

QUARTER WINDOW MOLDING (COUPE/MX-6)

Removal and Installation

1. Remove the seat belts.

2. Remove the rear header screw.

3. Remove the screws and the quarter trim.

4. Remove the screws and the center pillar trim.

5. Remove the quarter window molding mounting in-

stallation nuts.

6. Remove the screws and the quarter window

molding.

7. Install in the reverse order of removal.

76G14X-016

QUARTER WINDOW MOLDING

(HATCHBACK)

Removal and Installation

1. Remove the rear header screw.

2. Remove the bolt and the rear side seatback.

3. Remove the screws and the package side shelf.

4. Remove the screws and the rear pillar trim.

5. Remove the nuts and the quarter window molding.

6. Install in the reverse order of removal.

76G14X-017

QUARTER WINDOW MOLDING (SEDAN)

Removal and Installation

1. Remove the rear header screw.

2. Remove the bolt and the rear side seatback.

3. Remove the quarter trim.

4. Remove the nuts and the quarter window molding.

5. Install in the reverse order of removal.

86U14X-095

REAR WINDOW SIDE MOLDING (COUPE/MX-6)

Removal and Installation

1. Remove the seat belts.

2. Remove the rear header screw.

3. Remove the screws and the quarter side trim.

4. Remove the screws and the center pillar trim.

5. Remove the nuts and the rear window side

molding.

6. Install in the reverse order of removal.

76G14X-018

14-40

Page 1592 of 1865

MOLDING AND GARNISH 1 4

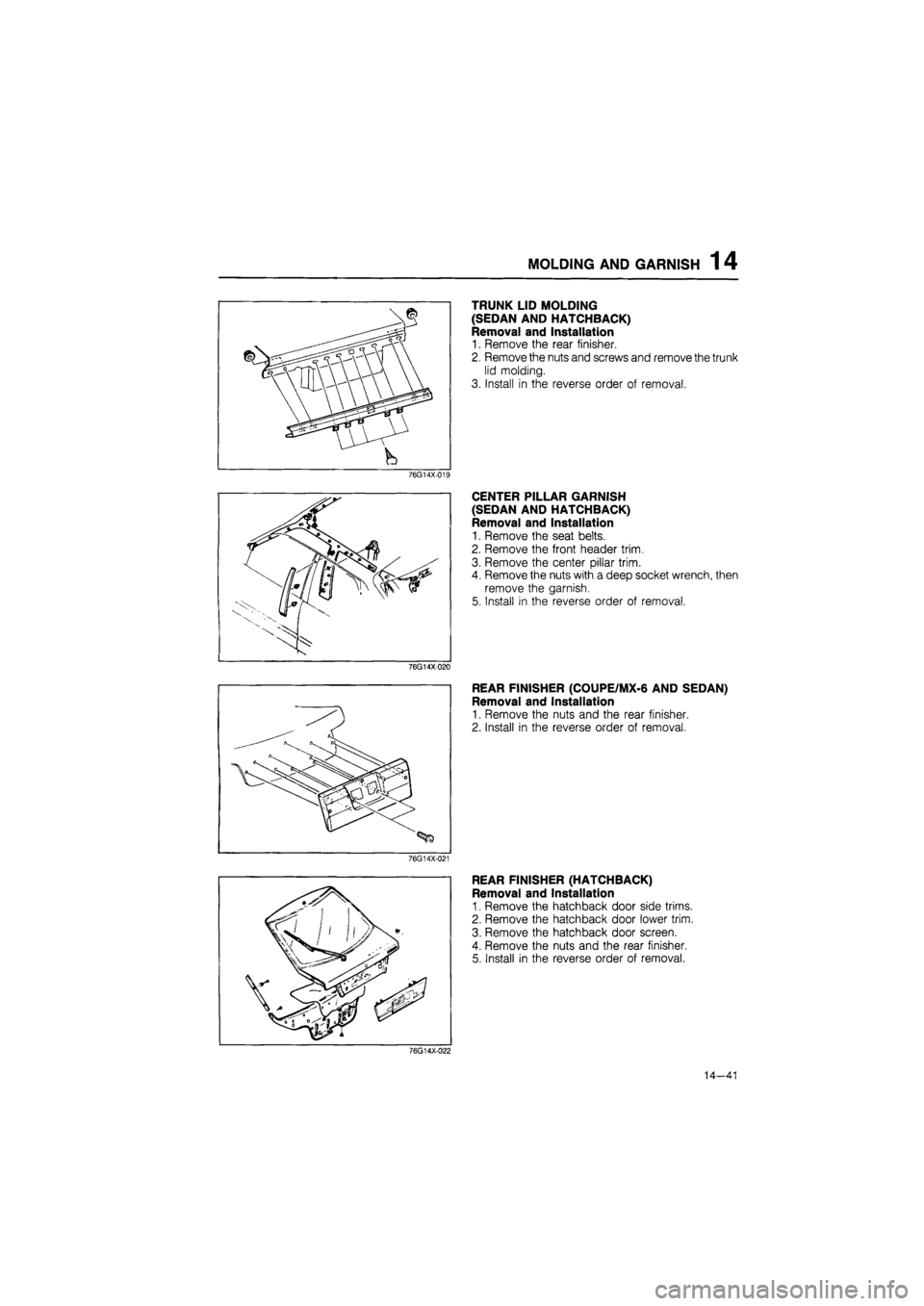

TRUNK LID MOLDING

(SEDAN AND HATCHBACK)

Removal and Installation

1. Remove the rear finisher.

2. Remove the nuts and screws and remove the trunk

lid molding.

3. Install in the reverse order of removal.

CENTER PILLAR GARNISH

(SEDAN AND HATCHBACK)

Removal and Installation

1. Remove the seat belts.

2. Remove the front header trim.

3. Remove the center pillar trim.

4. Remove the nuts with a deep socket wrench, then

remove the garnish.

5. Install in the reverse order of removal.

76G14X020

REAR FINISHER (COUPE/MX-6 AND SEDAN)

Removal and Installation

1. Remove the nuts and the rear finisher.

2. Install in the reverse order of removal.

76G14X-021

REAR FINISHER (HATCHBACK)

Removal and Installation

1. Remove the hatchback door side trims.

2. Remove the hatchback door lower trim.

3. Remove the hatchback door screen.

4. Remove the nuts and the rear finisher.

5. Install in the reverse order of removal.

76G14X-022

14—41

Page 1593 of 1865

1 4 MOLDING AND GARNISH

SAIL GARNISH

(SEDAN AND HATCHBACK)

Removal and Installation

1. Remove the sail inner garnish.

2. Remove the screws and remove the sail garnish.

3. Install in the reverse order of removal.

76G14X-023

SIDE PROTECTOR MOLDING

Structural View

86U14X-102

1. Side protector A molding 2. Side protector B molding 3. Side protector C molding

14-42

Page 1594 of 1865

SIDE

PROTECTOR MOLDING

1

4

Removal

1. Using a screwdriver or knife, twist the molding end,

being careful not to damage the painted surface,

and separate the adhesive for 20—30 mm

(0.79—1.18 in).

2. Pull the separated portion to remove it.

3. Use a knife to remove any adhesive remaining on

the body or molding.

Note

Remove as much adhesive as possible with-

out damaging the painted surface.

7BU14X-034

7BU14X-035

7BU14X-036

4. If the adhesive is difficult to remove, soften it with

a hot air blower.

Installation

1. Remove any grease or dirt from the molding adhe-

sion surface and the body surface.

2. Mark the installation position on the body with

masking tape.

3. Attach double-sided adhesive tape to the molding

adhesion surface.

4. Align the molding on the body, and attach it se-

curely.

Note

Adhesion conditions deteriorate if air temper-

ature is 20°C (68°F) or less; heating of the

body is thus recommended.

7BU14X-037

14—43

Page 1595 of 1865

1 4 DOOR MIRROR

DOOR MIRROR

DISASSEMBLY l ,

1 Warm the frame and the mirror glass with a lamp

(500W) to approx. 70°C (158°F) for approx. 3

minutes.

2. Insert a scraper between the mirror glass and the

frame, then pry the mirror loose.

3. Remove any remaining adhesive.

ASSEMBLY

1. Warm the frame with a lamp.

2. Install the glass in the frame, then gently press it

in to secure it.

86U14X-107

14—44

Page 1596 of 1865

TRUNK-LID

LOCK REMOTE RELEASE

1

4

TRUNK-LID LOCK REMOTE RELEASE

REMOVAL AND INSTALLATION

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

A 8 c D

1—

133

86U14X-108

1. Screws

2. Scuff plate

3. Screws

4. Cover

5. Bolts

6. Release lever

7. Release wire

14—45

Page 1597 of 1865

1 4 FUEL FILLER

LID

REMOTE RELEASE

FUEL FILLER

LID

REMOTE RELEASE

REMOVAL AND INSTALLATION

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

1. Screws 4. Cover 7. Release wire

2. Scuff plate 5. Bolts

3. Screws 6. Release lever

14—46

Page 1598 of 1865

WINDSHIELD GLASS 1 4

WINDSHIELD GLASS

STRUCTURAL VIEW

86U14X-110

1. Rear view mirror 4. Front pillar trim

2. Sunvisor 5. Wiper arm

3. Front header trim 6. Lower molding

Note

Use window tool set (49 0305 870A) to remove and install the glass.

7. Front windshield molding

8. Windshield glass

9. Spacer

14—47

Page 1599 of 1865

1 4 WINDSHIELD GLASS

REMOVAL

1. Remove the rearview mirror, sunvisors, front pillar

trim, and front header trim.

2. Remove the wiper arms and lower molding.

3. Remove the front window molding.

86U14X-111

Protective tape

Piano wire

Caution

Before removing the sealant, apply adhesive

tape to the body and instrument panel to pro-

tect them from damage.

86U14X-112

86U14X-113

4. Make a small hole through the sealant.

5. Pass the piano wire through the hole.

6. Wind each end of the wire around a bar.

7. Pull the wire to and fro, and saw through the seal-

ant around the edge of the glass. Then remove the

glass.

Caution

a) Use a long sawing action to spread the work

over the whole length of wire to prevent it

from breaking.

b) Be careful that the wire does not rub on the

body or instrument panel.

Note

If the glass is not to be reused, a tool like that

shown in the figure may be used.

Insert the blade in the sealant, and pull on the bars.

86U14X-114

14—48

Page 1600 of 1865

WINDSHIELD GLASS 1 4

INSTALLATION

1. Cut away the old sealant with a sharp knife so that

1 to 2 mm (0.04 to 0.08 in) thickness of sealant

remains around the circumference of the frame.

If all the sealant has come off in any one place,

apply some primer after degreasing, and allow it

30 minutes to dry. Then put on new sealant to

build up to a 2 mm (0.08 in) layer

86U14X-115

2. Carefully clean a 5 cm (1.97 in) wide area around

the circumference of the glass and the bond on

the body.

3. Bond a new dam along the circumference of the

glass 5 mm (0.20 in) from the edge.

Caution

Securely bond the dam and allow it to dry.

86U14X-116

4. Apply primer with a brush to the bonding area of

the glass and the body, and allow it to dry for ap-

prox. 30 minutes.

Caution

Keep the area free of dirt. Do not touch the

surface. If primer gets on the hands, remove

it immediately.

86U14X-117

5. Bond the spacers to the body as shown.

Caution

Damaged spacers must be replaced.

76G14X-043

expert22 f

n http://rutracker.org

Trending: window, engine overheat, battery replacement, rear view mirror, fuel consumption, jump start, fuel