MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 291 of 1146

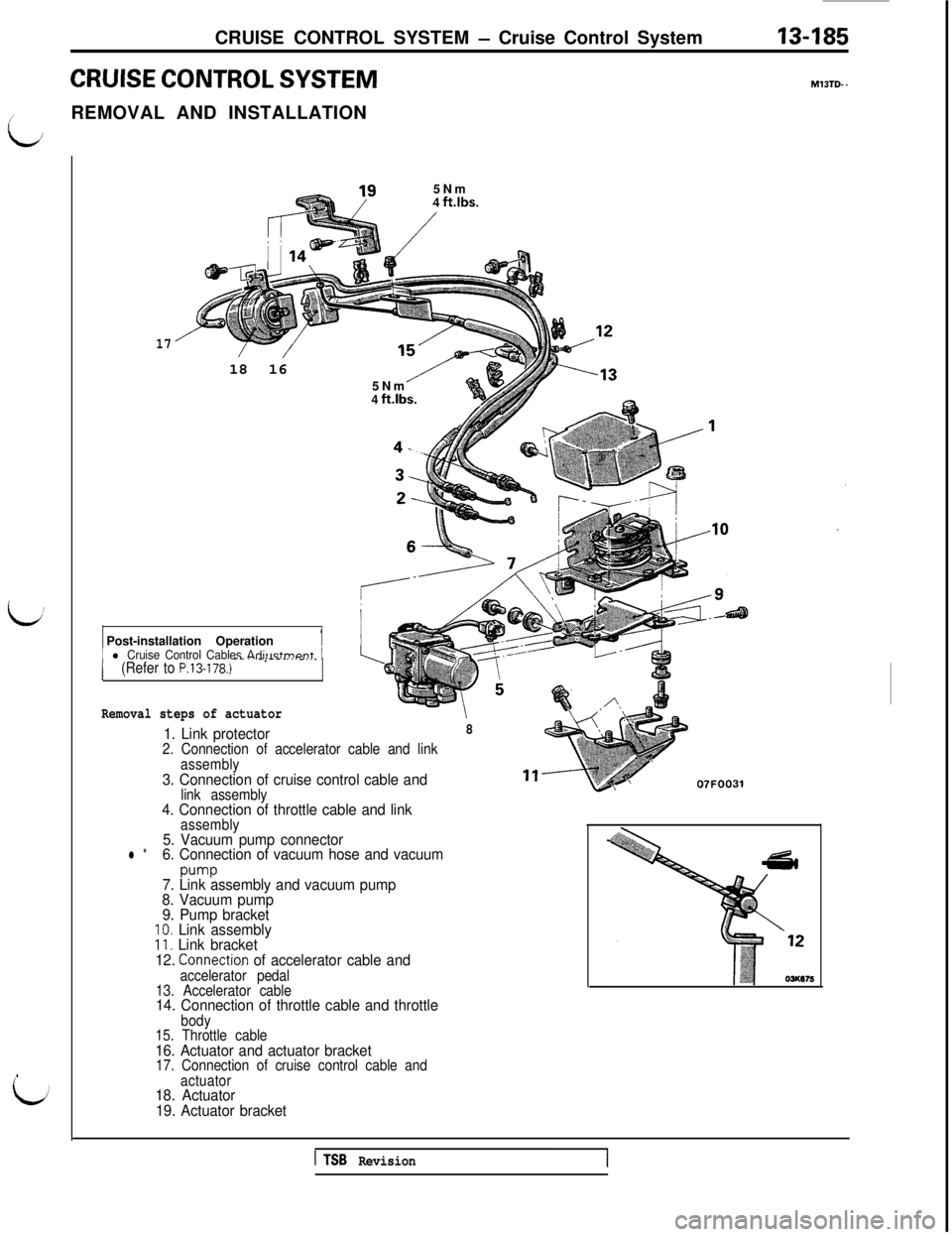

CRUISE CONTROL SYSTEM - Cruise Control System13-185

CRUISE CONTROL SYSTEMM13TD. -

L;REMOVAL AND INSTALLATION

5Nm

4

ft.lbs.

h :

17P18 16

5Nm

4

ft.lbs.7Post-installation Operation

11 l Cruise Control Cables Adillstmcwt 1j(Refer to P.13-178.)--’ -->---“‘-.,-

Removal steps of actuator

81. Link protector2. Connection of accelerator cable and link

assembly

3. Connection of cruise control cable andlink assembly4. Connection of throttle cable and linkassembly5. Vacuum pump connectorl *6. Connection of vacuum hose and vacuum

pump7. Link assembly and vacuum pump

8. Vacuum pump

9. Pump bracket

IO. Link assembly11. Link bracket

12. Connecti0.n of accelerator cable andaccelerator pedal

13. Accelerator cable

14. Connection of throttle cable and throttlebody

15. Throttle cable

16. Actuator and actuator bracket17. Connection of cruise control cable and,

Ld

actuator18. Actuator

19. Actuator bracket

07FOO31

1 TSB Revision

Page 292 of 1146

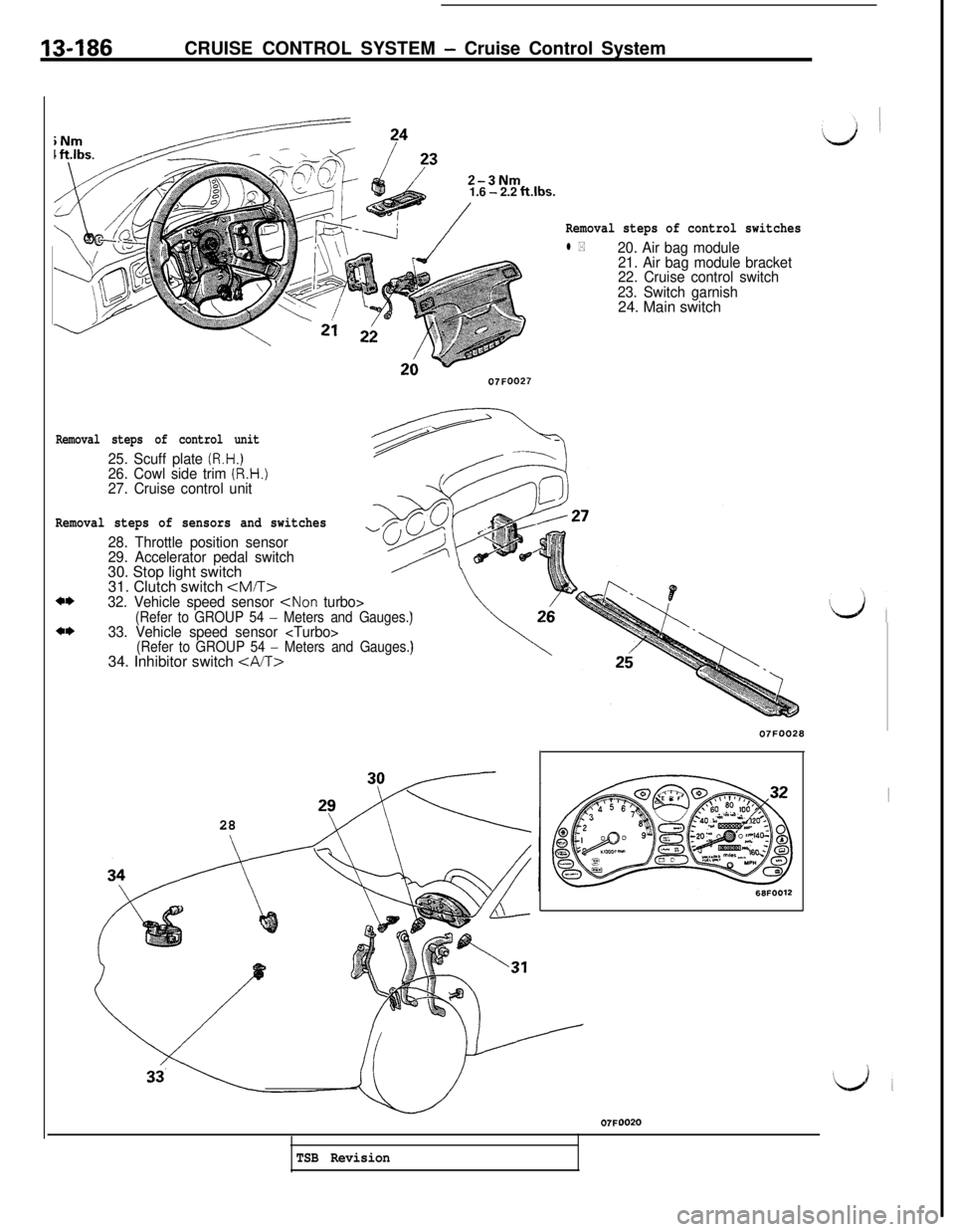

13486CRUISE CONTROL SYSTEM - Cruise Control System

1.6

- 2.2 ft.lbs.

07FOO27

Removal steps of control switches

l *20. Air bag module

21. Air bag module bracket

22. Cruise control switch

23. Switch garnish24. Main switch

Removal steps of sensors and switches

28. Throttle position sensor

29. Accelerator pedal switch30. Stop light switch

31. Clutch switch

4*

4*

Removal steps of control unit

25. Scuff plate (R.H.)26. Cowl side trim (R.H.)27. Cruise control unit34. Inhibitor switch

2807FOO28

68FOO12

07FOO20

TSB Revision

Page 293 of 1146

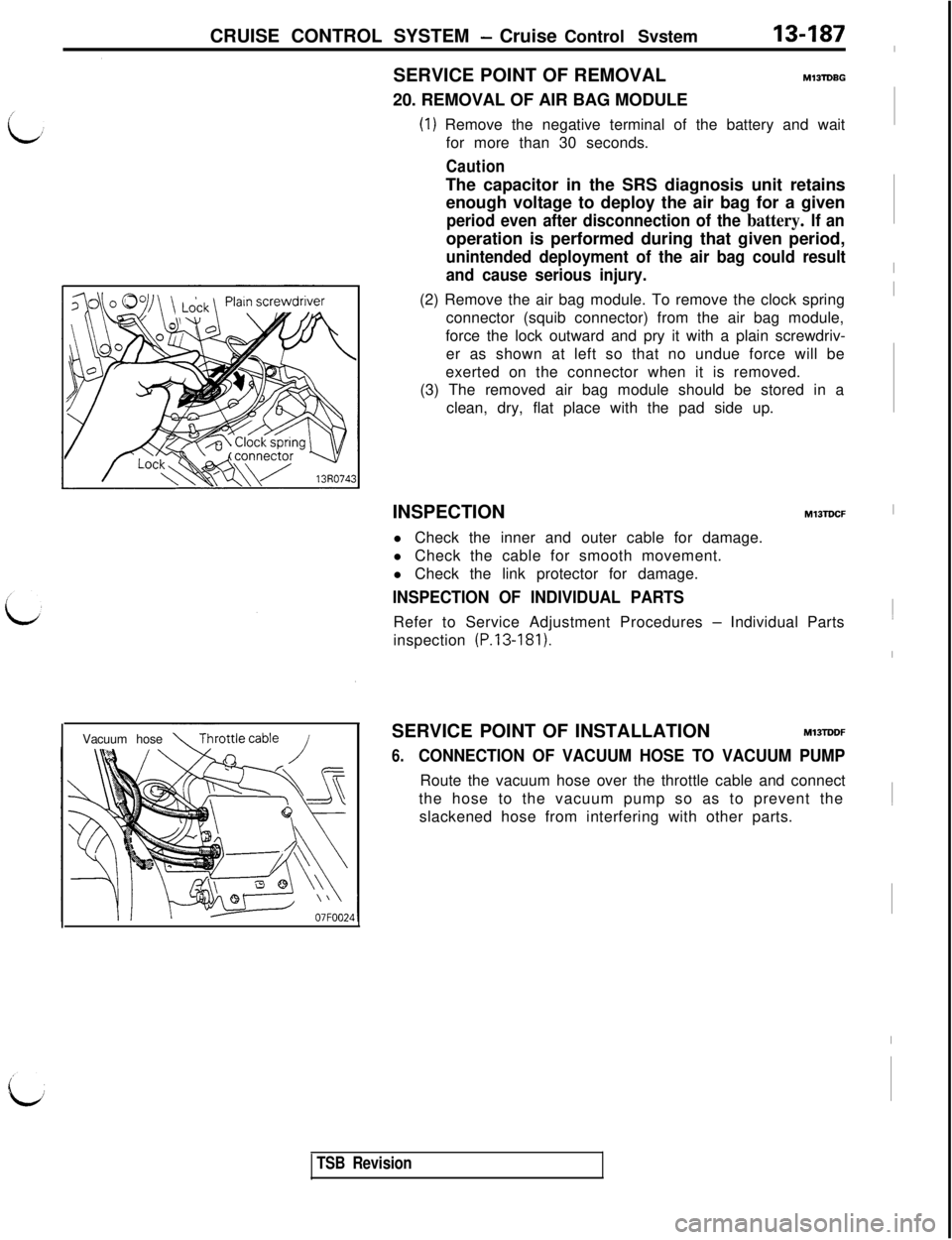

CRUISE CONTROL SYSTEM - Cruise Control Svstem13-187Vacuum hoseSERVICE POINT OF REMOVAL

Ml3lDBG20. REMOVAL OF AIR BAG MODULE

(1) Remove the negative terminal of the battery and wait

for more than 30 seconds.

CautionThe capacitor in the SRS diagnosis unit retains

enough voltage to deploy the air bag for a given

period even after disconnection of the battery. If anoperation is performed during that given period,

unintended deployment of the air bag could result

and cause serious injury.(2) Remove the air bag module. To remove the clock spring

connector (squib connector) from the air bag module,

force the lock outward and pry it with a plain screwdriv-

er as shown at left so that no undue force will be

exerted on the connector when it is removed.

(3) The removed air bag module should be stored in a

clean, dry, flat place with the pad side up.

INSPECTION

MlJTDCFl Check the inner and outer cable for damage.

l Check the cable for smooth movement.

l Check the link protector for damage.

INSPECTION OF INDIVIDUAL PARTSRefer to Service Adjustment Procedures

- Individual Parts

inspection (P.l3-181).

SERVICE POINT OF INSTALLATION

M13TDDF

6.CONNECTION OF VACUUM HOSE TO VACUUM PUMPRoute the vacuum hose over the throttle cable and connect

the hose to the vacuum pump so as to prevent the

slackened hose from interfering with other parts.

TSB Revision

I

I

I

I~

I~~

I

Page 294 of 1146

Page 295 of 1146

COOLINGCONTENTS

M14AA..

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT TEMPERATURESENSOR AND ENGINE COOLANT

TEMPERATURE SWITCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.__15

RADIATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SERVICE ADJUSTMENT PROCEDURES . . . . . . . .7Cap Pressure Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.......7Engine Coolant Concentration Test

. . . . . . . . . . . . . . . .‘7

L,Engine Coolant Leak Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . .7Engine Coolant Replacement

. . . . . . . . . . . . . . . . . . . . . . . .7

SPECIFICATIONS. . . . . . . . . . . . .._.................................General Specifications

. ..___....___._...___.__............Lubricant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.................._........Sealant and Adhesive

. . . . . . . . . . . . . . . . .._...........Service Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . .

THERMOSTAT. . . ..__......................_.._...................

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...No Rise in Temperature

Overheat

WATER PUMP, WATER PIPE AND WATER

HOSE. . . . _......_........_ _.._ .._..... . . . . . . . . . . . ._. . . . . . . . . . . . . . . . .

2

2

2

3

2

11

3

13

Page 296 of 1146

14-2COOLING - SDecifications

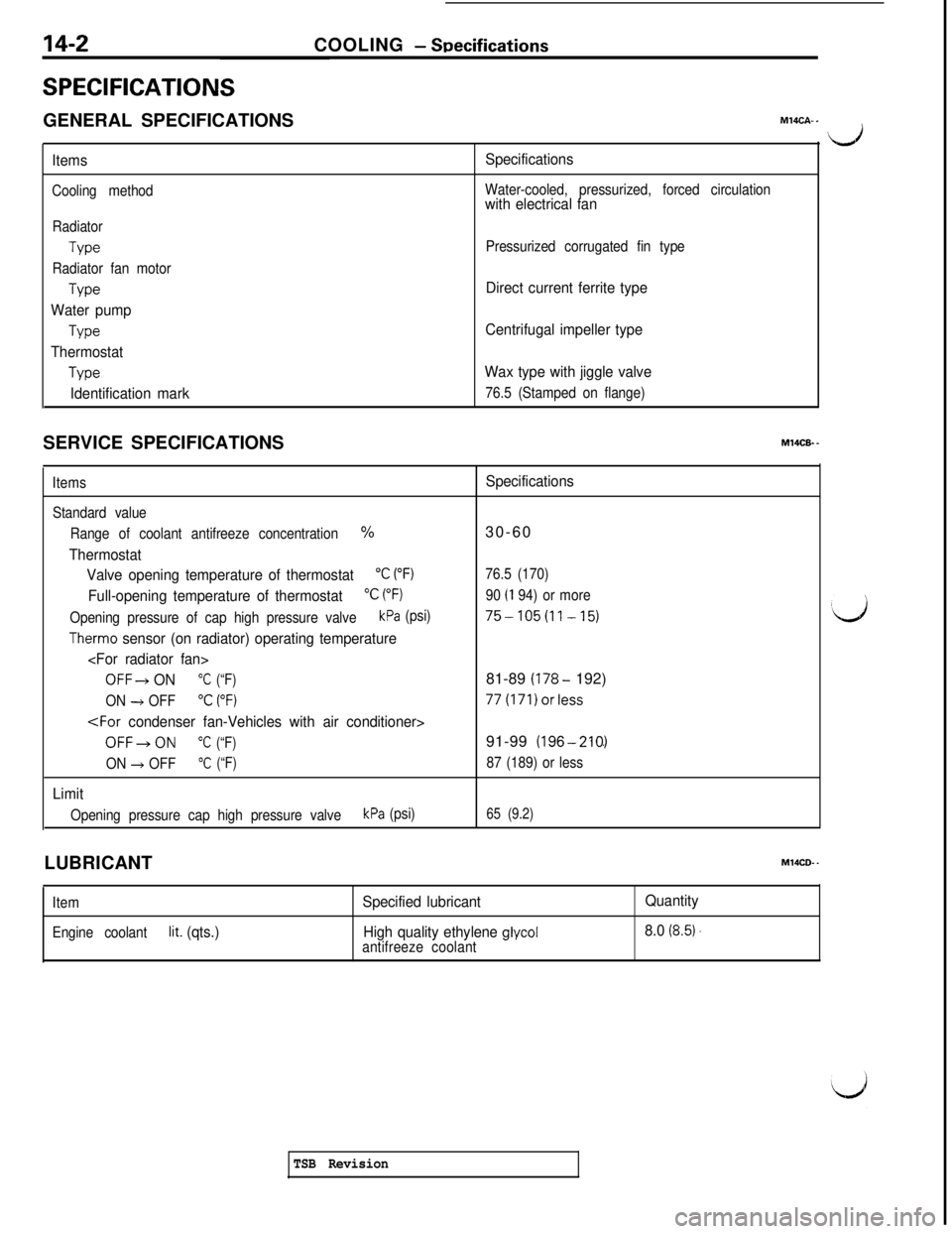

SPECIFICATIONSGENERAL SPECIFICATIONSMMCA..

Items

Cooling method

Radiator

Type

Radiator fan motor

Type

Water pump

Type

Thermostat

Type

Identification markSpecifications

Water-cooled, pressurized, forced circulationwith electrical fan

Pressurized corrugated fin type

Direct current ferrite type

Centrifugal impeller type

Wax type with jiggle valve

76.5 (Stamped on flange)

dSERVICE SPECIFICATIONS

Items

Standard valueSpecifications

Range of coolant antifreeze concentration%30-60

Thermostat

Valve opening temperature of thermostat

“C (“F)

Full-opening temperature of thermostat“C (“F)

Opening pressure of cap high pressure valvekPa (psi)

Therm0 sensor (on radiator) operating temperature

OFF-t ON“C (“F)

ON -+ OFF“C (“F)

OFF-ON“C (“F)

ON + OFF“C (“F)

Limit

76.5 (170)

90

(I 94) or more

75-105(11-15)81-89

(178- 192)77(171)orless

91-99

(196-210.)

87 (189) or less

Opening pressure cap high pressure valve

kPa (psi)65 (9.2)LUBRICANT

MlQCD- -

ItemSpecified lubricantQuantity

Engine coolantlit. (qts.)High quality ethylene glycol8.0 (8.5).

antifreeze coolant

‘d

TSB Revision

Page 297 of 1146

COOLING - Specifications / Troubleshooting

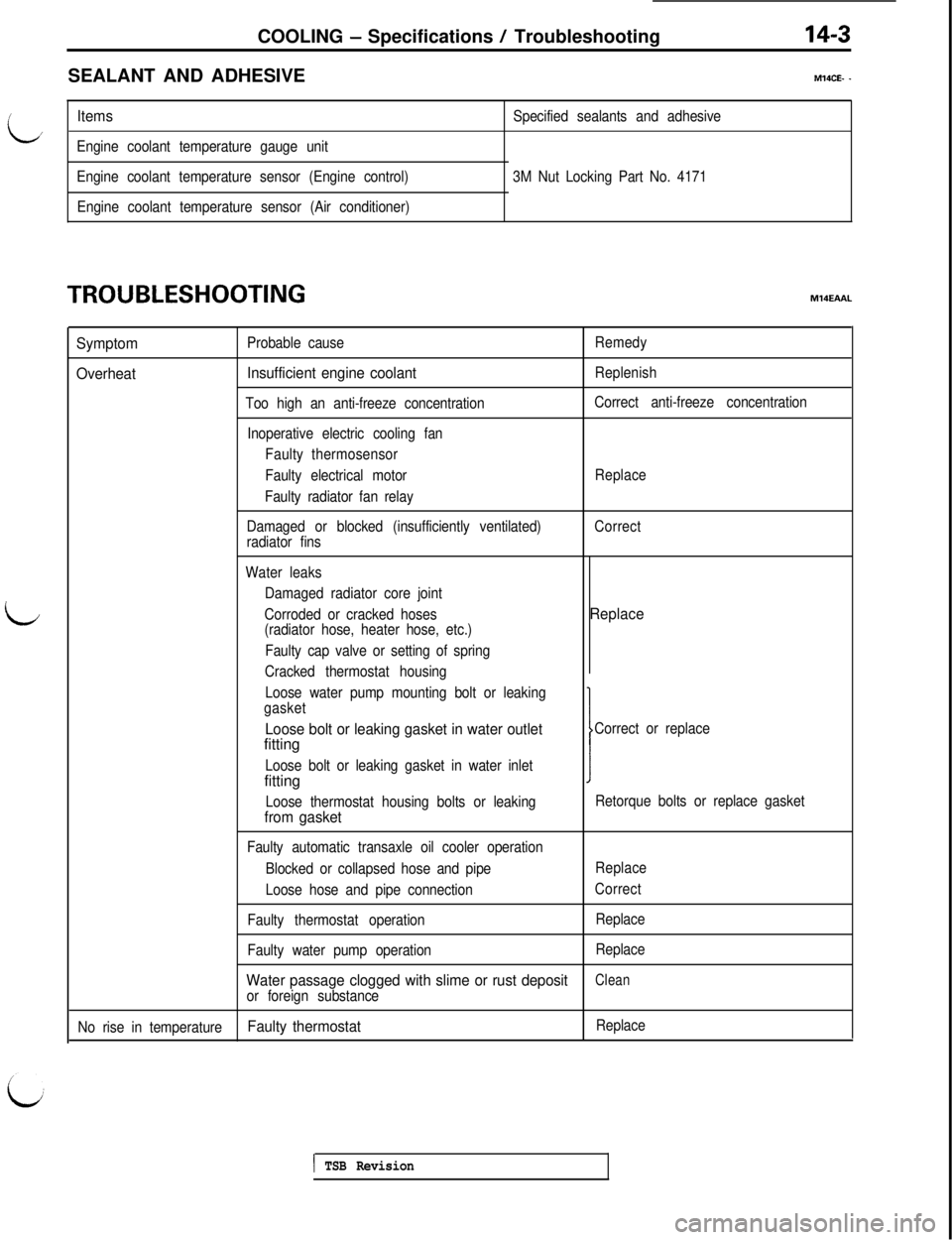

SEALANT AND ADHESIVE14-3

MMCE- -

/

id

ItemsSpecified sealants and adhesive/

Engine coolant temperature gauge unit

Engine coolant temperature sensor (Engine control)

Engine coolant temperature sensor (Air conditioner)3M Nut Locking Part No. 4171

TROUBLESHOOTING

L

MllEAAL

Symptom

OverheatProbable cause

Insufficient engine coolant

Too high an anti-freeze concentration

Inoperative electric cooling fan

Faulty thermosensor

Faulty electrical motor

Faulty radiator fan relayRemedy

Replenish

Correct anti-freeze concentration

Replace

Damaged or blocked (insufficiently ventilated)

radiator finsCorrect

Water leaks

Damaged radiator core joint

Corroded or cracked hoses

(radiator hose, heater hose, etc.)

Faulty cap valve or setting of spring

Cracked thermostat housing

Loose water pump mounting bolt or leaking

gasket

Replace

Loose bolt or leaking gasket in water outlet

I

Correct or replacefitting

Loose bolt or leaking gasket in water inletfitting

Loose thermostat housing bolts or leakingfrom gasket

Retorque bolts or replace gasket

Faulty automatic transaxle oil cooler operation

Blocked or collapsed hose and pipeReplace

Loose hose and pipe connectionCorrect

Faulty thermostat operationReplace

Faulty water pump operationReplace

Water passage clogged with slime or rust depositClean

or foreign substance

No rise in temperature

Faulty thermostatReplace

( TSB Revision

Page 298 of 1146

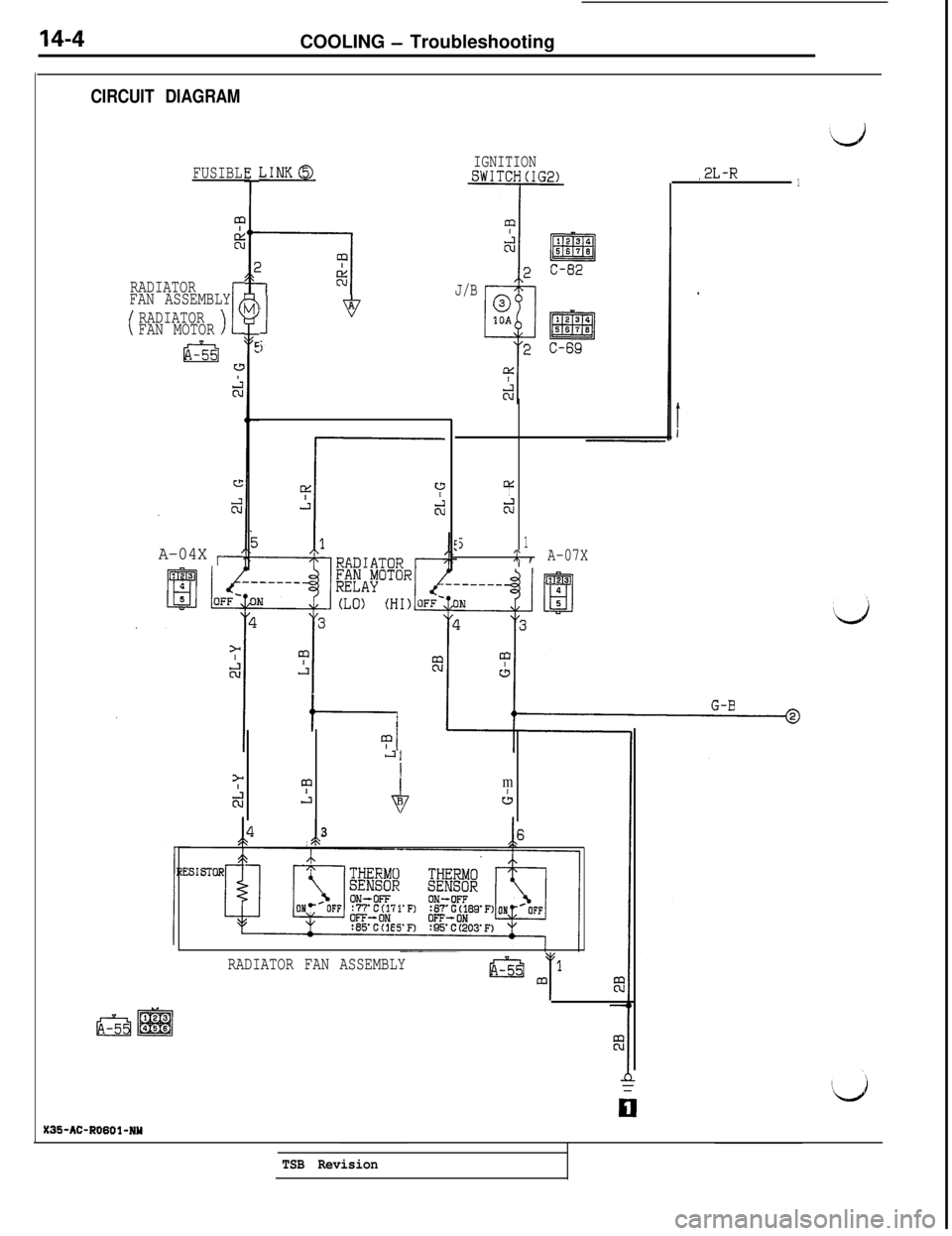

14-4COOLING - Troubleshooting

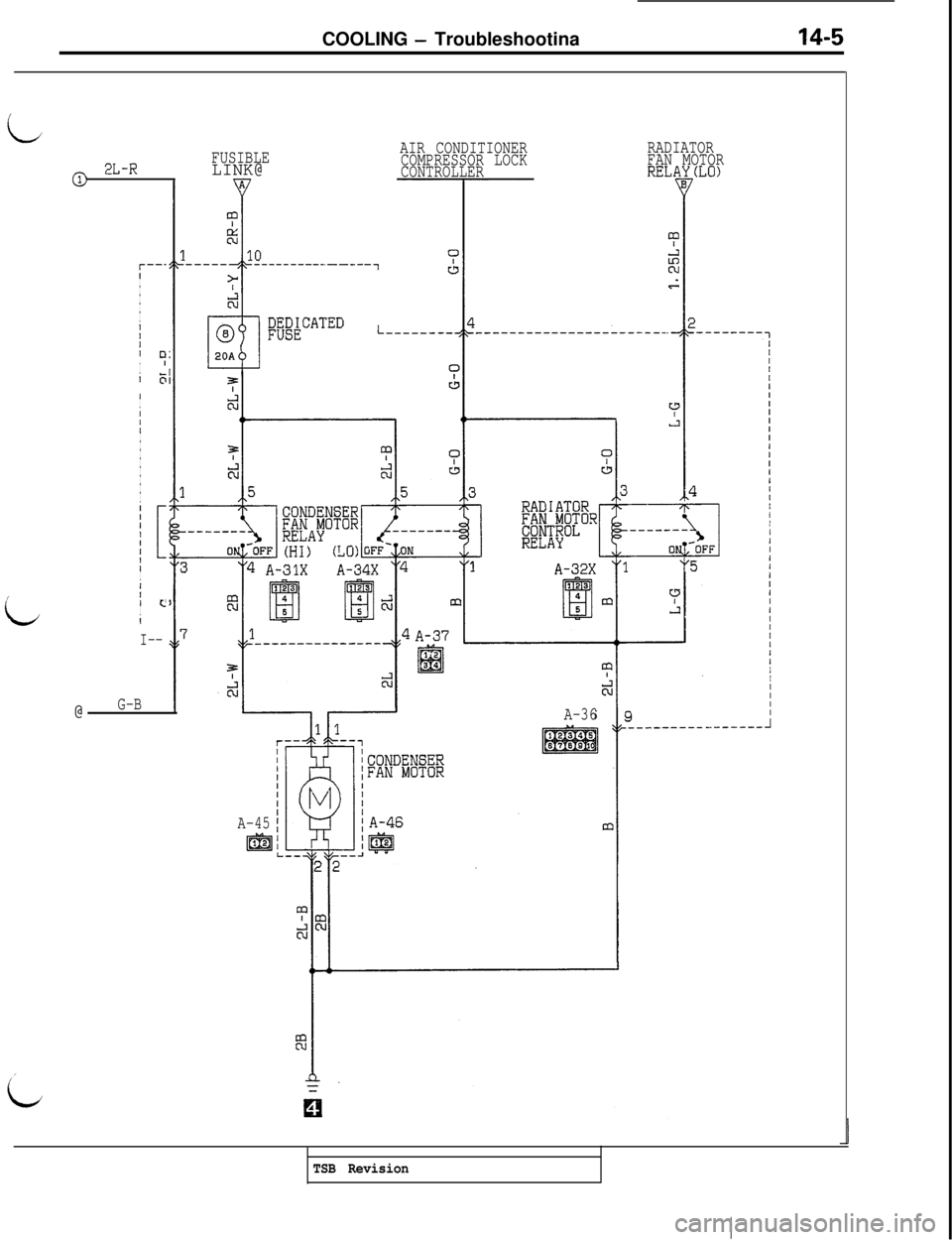

CIRCUIT DIAGRAM

FUSIBL

RADIATOR

FAN ASSEMBLY

(RADIATOR

,

FAN MOTOR>r{

!&w

F

A-04X ,---LINK0

J

0A

j

IGNITION

J/B

lxI

ti

51.: ,A-07X

J1

>II

ticpLi6

m

R&

b3

,2L-R1

RADIATOR FAN ASSEMBLYL!a ml

T

X35-AC-NWOl-NY

TSB Revision

Page 299 of 1146

COOLING - Troubleshootina14-5

i

L

@2L-R

:---I

I

I

I

I

III1 nI

I

1 6IIIII

I

I

I

I

I

I

I

I

ii

II

! cI1

I--@

G-B

FUSIBLELINK@

_------ __._ -_--

L-

AIR CONDITIONER

COMPRESSOR LOCK

CONTROLLERRADIATOR

FAN MOTOR

RELAYCLO)

A-36

A-45

@!A

TSB Revision

Page 300 of 1146

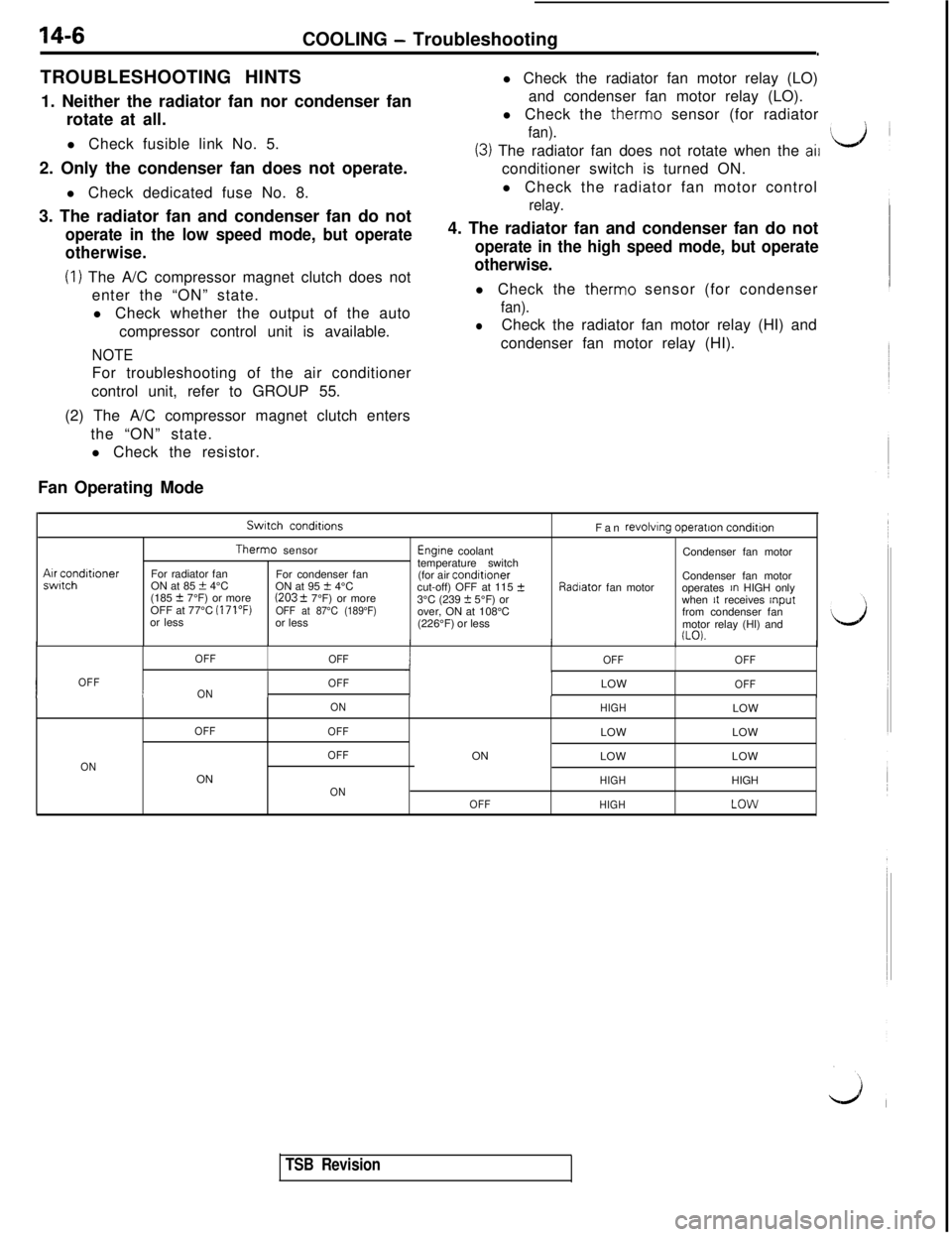

14-6COOLING - Troubleshooting.TROUBLESHOOTING HINTS

1. Neither the radiator fan nor condenser fan

rotate at all.

l Check fusible link No. 5.

2. Only the condenser fan does not operate.

l Check dedicated fuse No. 8.

3. The radiator fan and condenser fan do not

operate in the low speed mode, but operate

otherwise.

(1) The A/C compressor magnet clutch does not

enter the “ON” state.

l Check whether the output of the auto

compressor control unit is available.

NOTEFor troubleshooting of the air conditioner

control unit, refer to GROUP 55.

(2) The A/C compressor magnet clutch enters

the “ON” state.

l Check the resistor.

Fan Operating Model Check the radiator fan motor relay (LO)

and condenser fan motor relay (LO).

l Check the therm0 sensor (for radiator

fan).

(3) The radiator fan does not rotate when the ailconditioner switch is turned ON.

l Check the radiator fan motor control

relay.4. The radiator fan and condenser fan do not

operate in the high speed mode, but operate

otherwise.l Check the therm0 sensor (for condenser

fan).

lCheck the radiator fan motor relay (HI) and

condenser fan motor relay (HI).Air

conditionerswitch

Switch conditionsTherm0 sensor

For radiator fan

For condenser fan

ON at 85

k 4°C

ON at 95 t 4°C

(185 f 7°F) or more(203 + 7°F) or more

OFF at 77°C (171°F)

OFF at 87°C (189°F)or less

or lessEngine coolant

temperature switch

(for air conditioner

cut-off) OFF at 115

+3°C (239 2 5°F) or

over, ON at 108°C

(226°F) or lessFan revolving operation

conditionCondenser fan motor

Condenser fan motorRadiator fan motor

operates

In HIGH only

when it receives input

from condenser fan

motor relay (HI) and

U-0).I/I/

OFF

OFF

OFFOFF

IOFFIOFF

ONLOWOFF

ON

HIGHLOW

OFF

OFFLOWLOW

OFF

ONON

LOWLOW

ON

HIGH

ONHIGH

OFF

HIGHLOW

TSB Revision