NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: fuel cap release, service indicator, seats, checking oil, seat adjustment, height, overheating

Page 951 of 1659

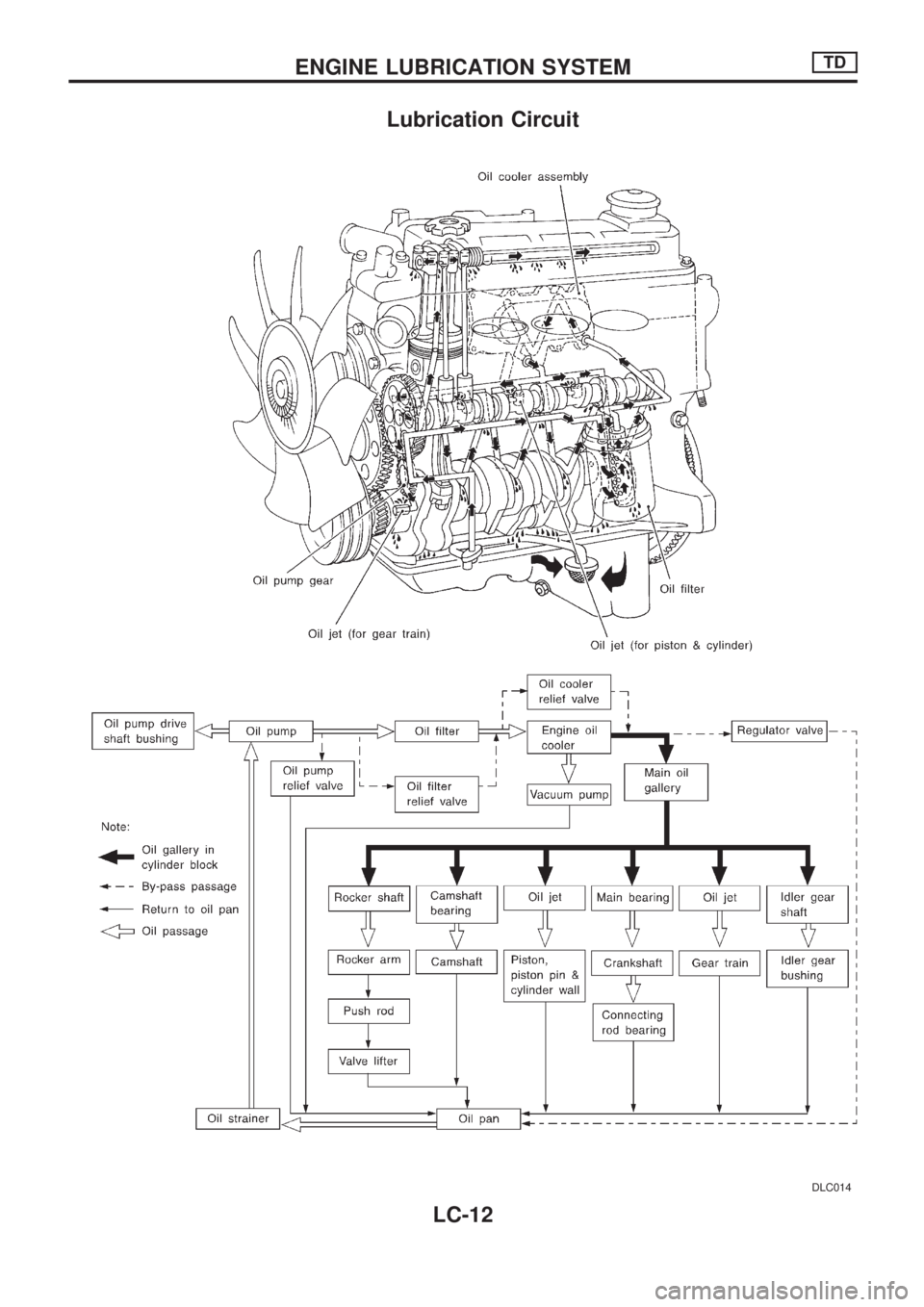

Lubrication Circuit

DLC014

ENGINE LUBRICATION SYSTEMTD

LC-12

Page 952 of 1659

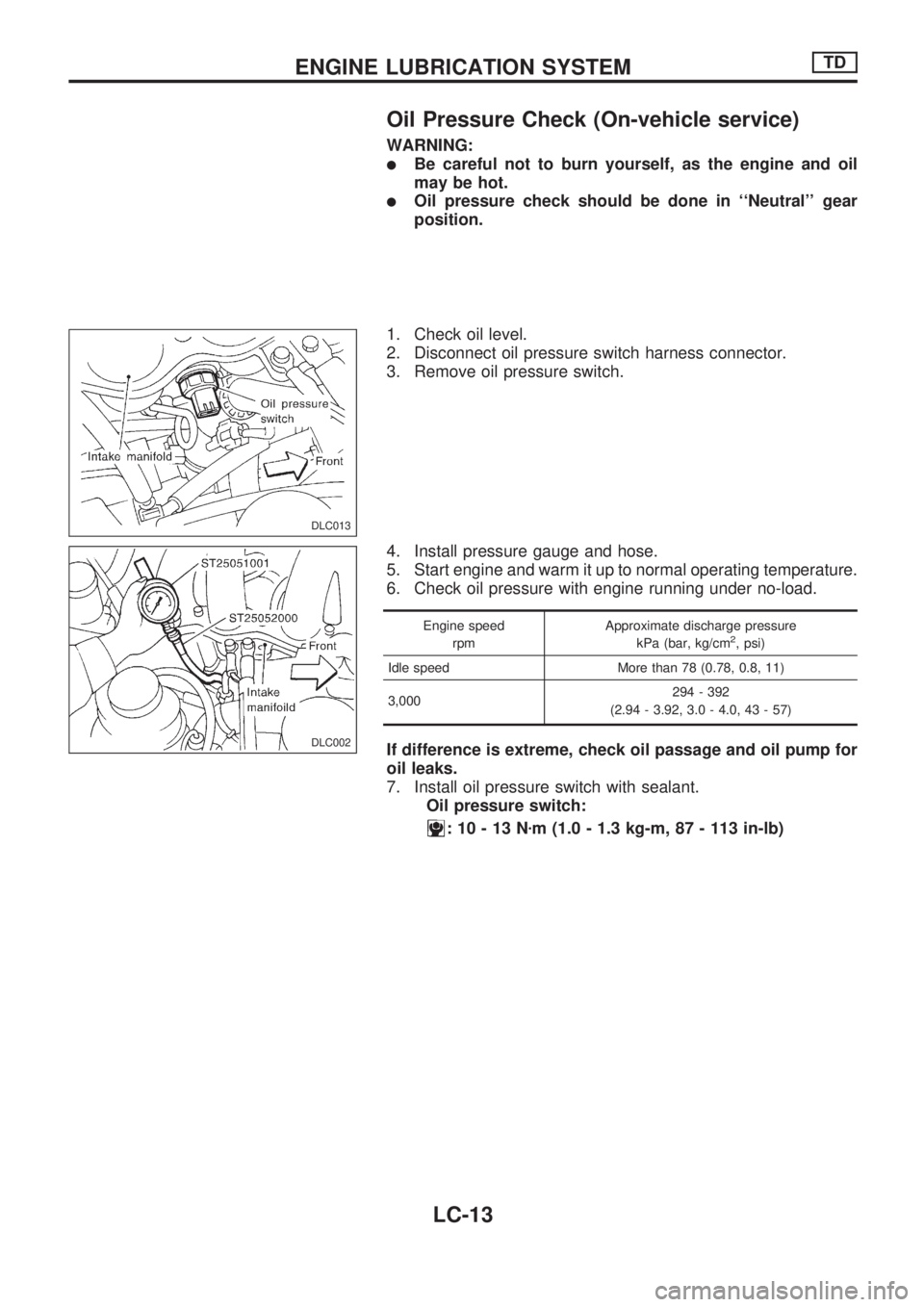

Oil Pressure Check (On-vehicle service)

WARNING:

lBe careful not to burn yourself, as the engine and oil

may be hot.

lOil pressure check should be done in ``Neutral'' gear

position.

1. Check oil level.

2. Disconnect oil pressure switch harness connector.

3. Remove oil pressure switch.

4. Install pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 78 (0.78, 0.8, 11)

3,000294 - 392

(2.94 - 3.92, 3.0 - 4.0, 43 - 57)

If difference is extreme, check oil passage and oil pump for

oil leaks.

7. Install oil pressure switch with sealant.

Oil pressure switch:

:10-13Nzm (1.0 - 1.3 kg-m, 87 - 113 in-lb)

DLC013

DLC002

ENGINE LUBRICATION SYSTEMTD

LC-13

Page 953 of 1659

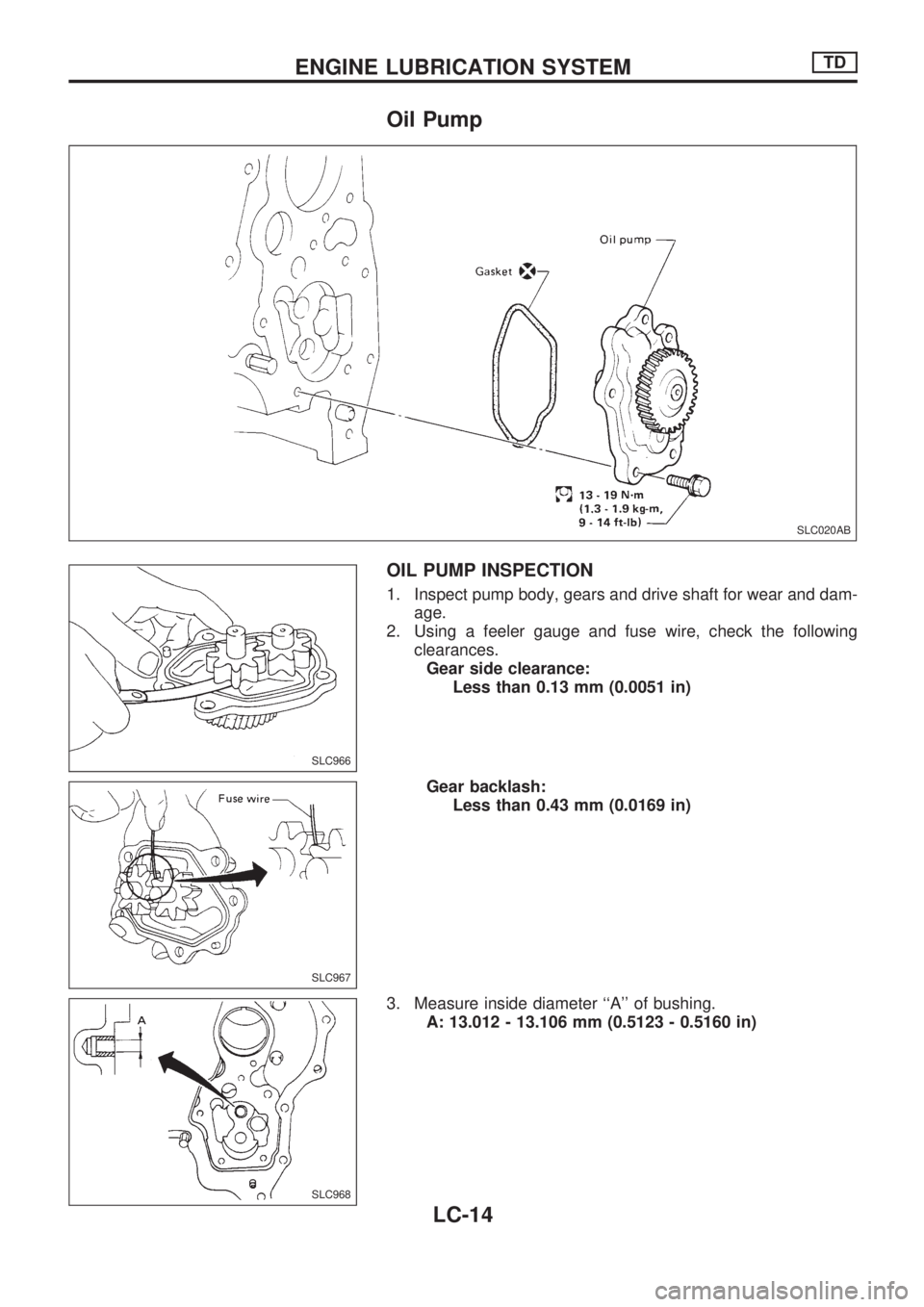

Oil Pump

OIL PUMP INSPECTION

1. Inspect pump body, gears and drive shaft for wear and dam-

age.

2. Using a feeler gauge and fuse wire, check the following

clearances.

Gear side clearance:

Less than 0.13 mm (0.0051 in)

Gear backlash:

Less than 0.43 mm (0.0169 in)

3. Measure inside diameter ``A'' of bushing.

A: 13.012 - 13.106 mm (0.5123 - 0.5160 in)

SLC020AB

SLC966

SLC967

SLC968

ENGINE LUBRICATION SYSTEMTD

LC-14

Page 954 of 1659

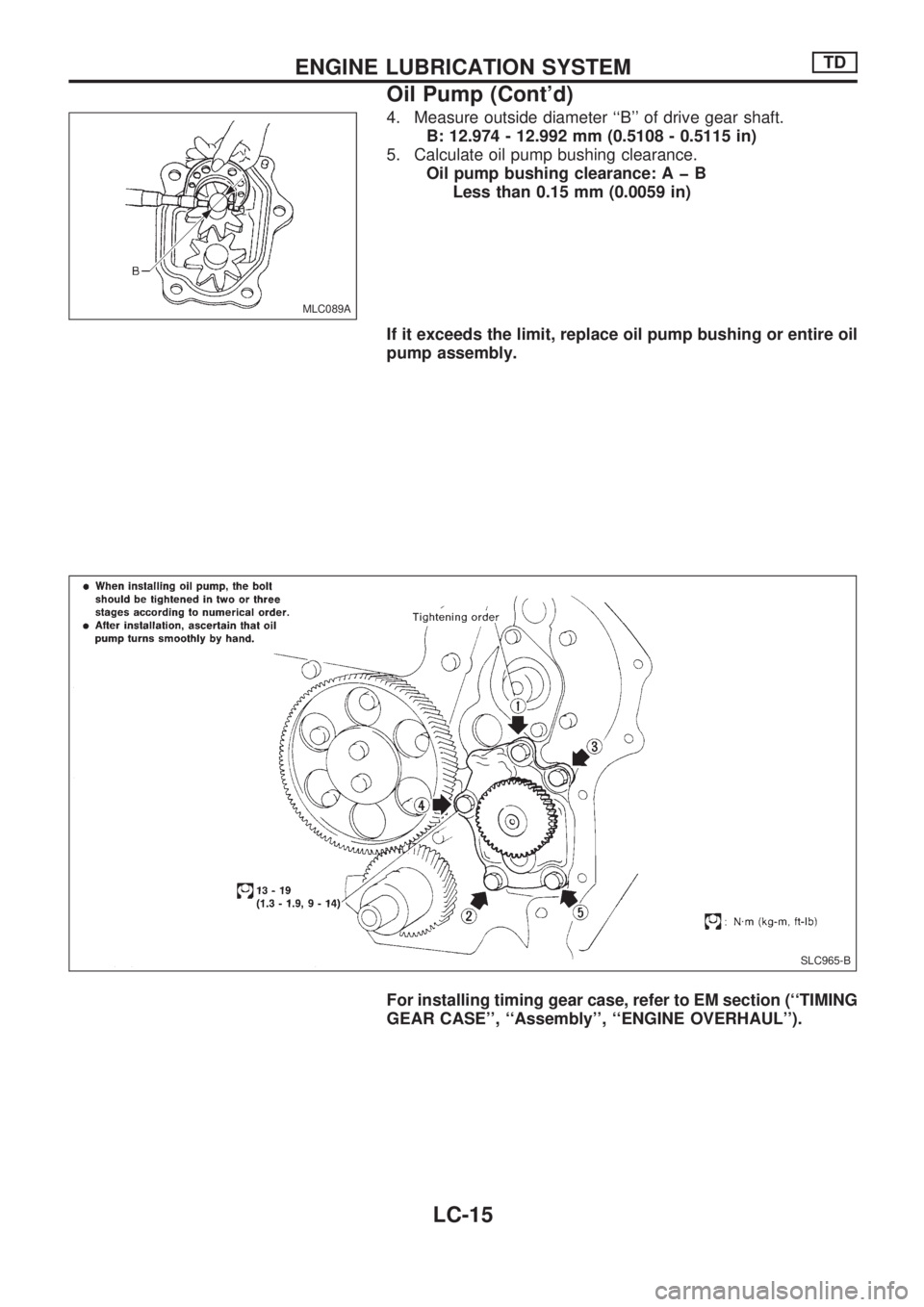

4. Measure outside diameter ``B'' of drive gear shaft.

B: 12.974 - 12.992 mm (0.5108 - 0.5115 in)

5. Calculate oil pump bushing clearance.

Oil pump bushing clearance:AþB

Less than 0.15 mm (0.0059 in)

If it exceeds the limit, replace oil pump bushing or entire oil

pump assembly.

For installing timing gear case, refer to EM section (``TIMING

GEAR CASE'', ``Assembly'', ``ENGINE OVERHAUL'').

MLC089A

SLC965-B

ENGINE LUBRICATION SYSTEMTD

Oil Pump (Cont'd)

LC-15

Page 955 of 1659

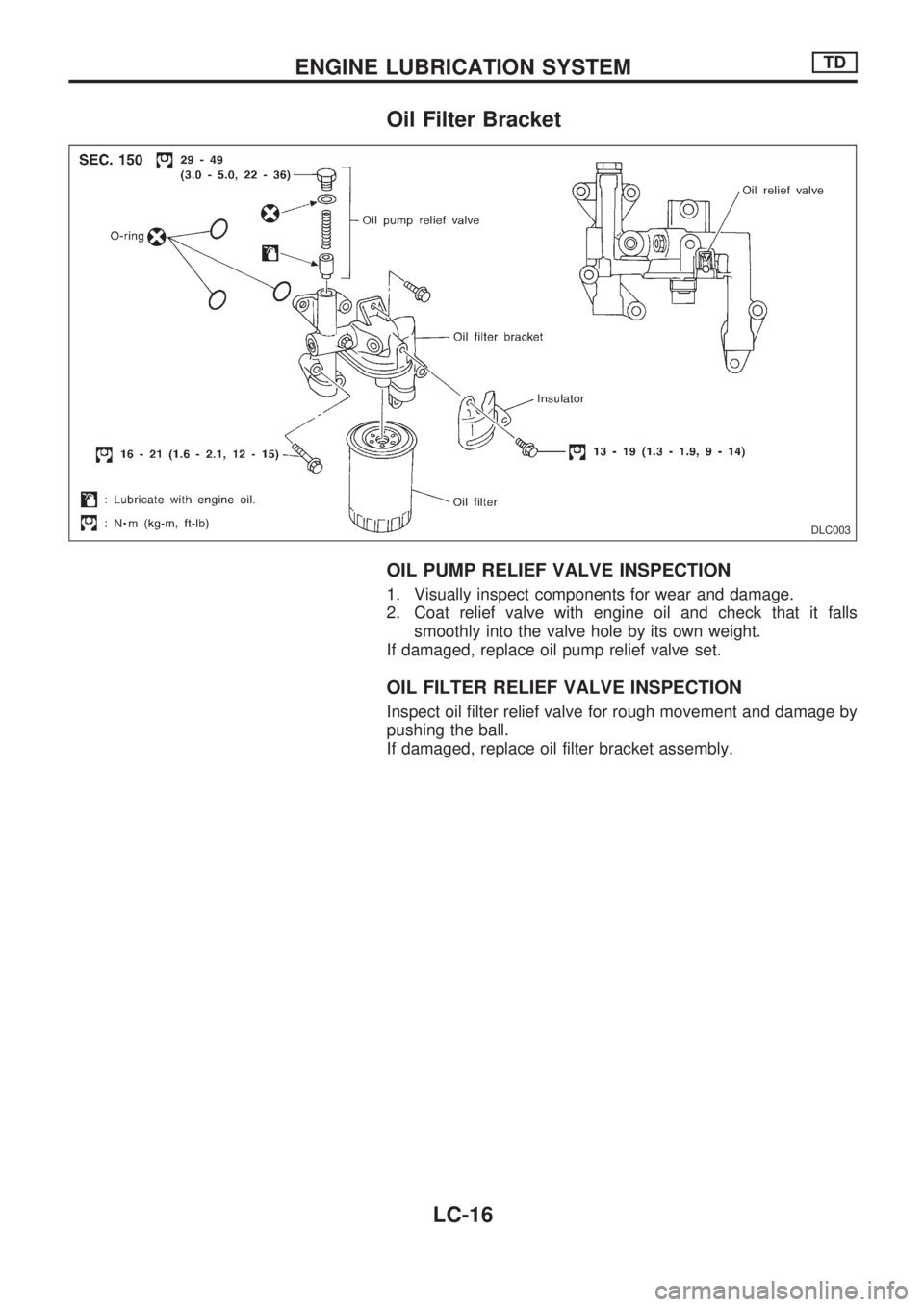

Oil Filter Bracket

OIL PUMP RELIEF VALVE INSPECTION

1. Visually inspect components for wear and damage.

2. Coat relief valve with engine oil and check that it falls

smoothly into the valve hole by its own weight.

If damaged, replace oil pump relief valve set.

OIL FILTER RELIEF VALVE INSPECTION

Inspect oil filter relief valve for rough movement and damage by

pushing the ball.

If damaged, replace oil filter bracket assembly.

DLC003

ENGINE LUBRICATION SYSTEMTD

LC-16

Page 956 of 1659

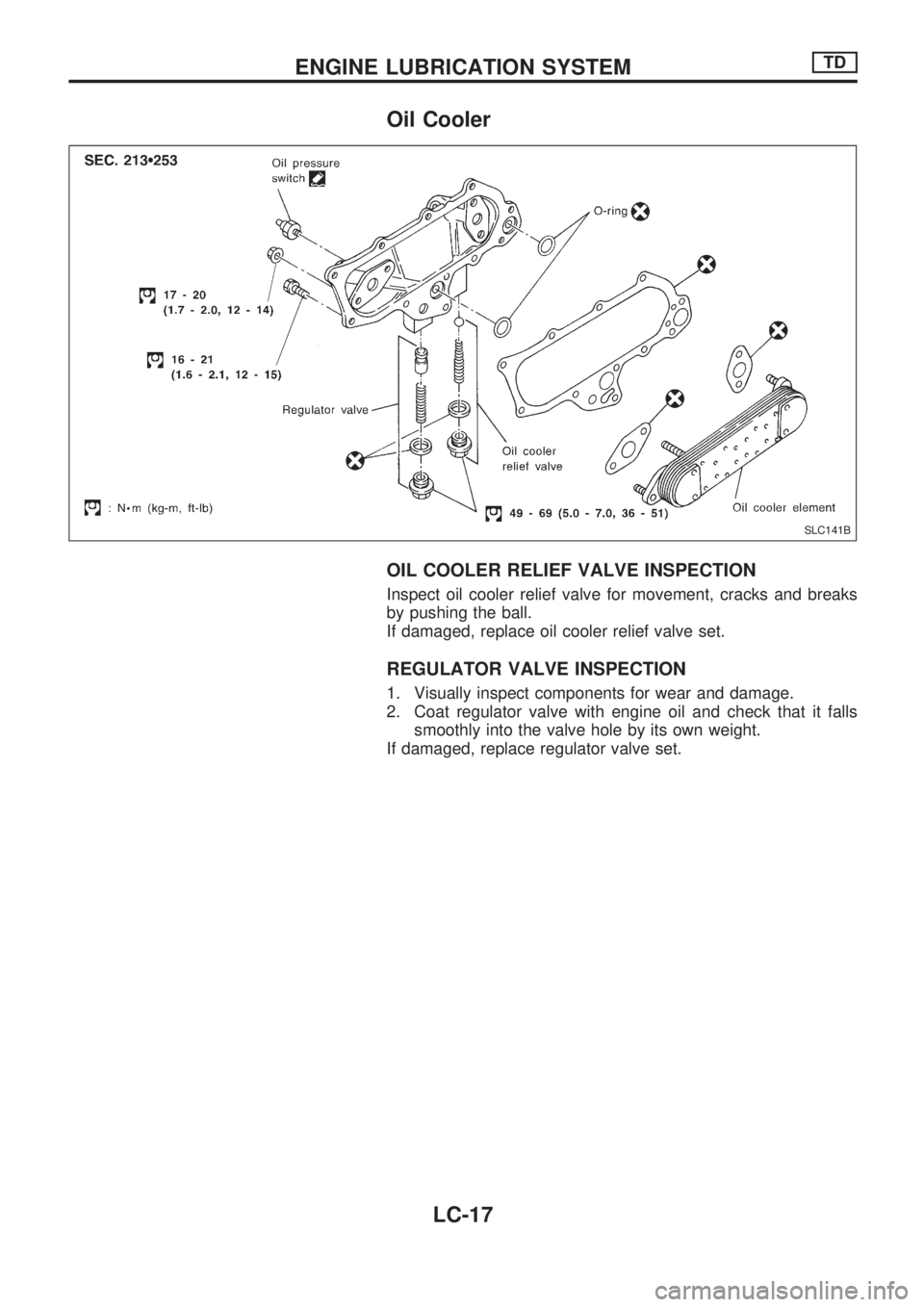

Oil Cooler

OIL COOLER RELIEF VALVE INSPECTION

Inspect oil cooler relief valve for movement, cracks and breaks

by pushing the ball.

If damaged, replace oil cooler relief valve set.

REGULATOR VALVE INSPECTION

1. Visually inspect components for wear and damage.

2. Coat regulator valve with engine oil and check that it falls

smoothly into the valve hole by its own weight.

If damaged, replace regulator valve set.

SLC141B

ENGINE LUBRICATION SYSTEMTD

LC-17

Page 957 of 1659

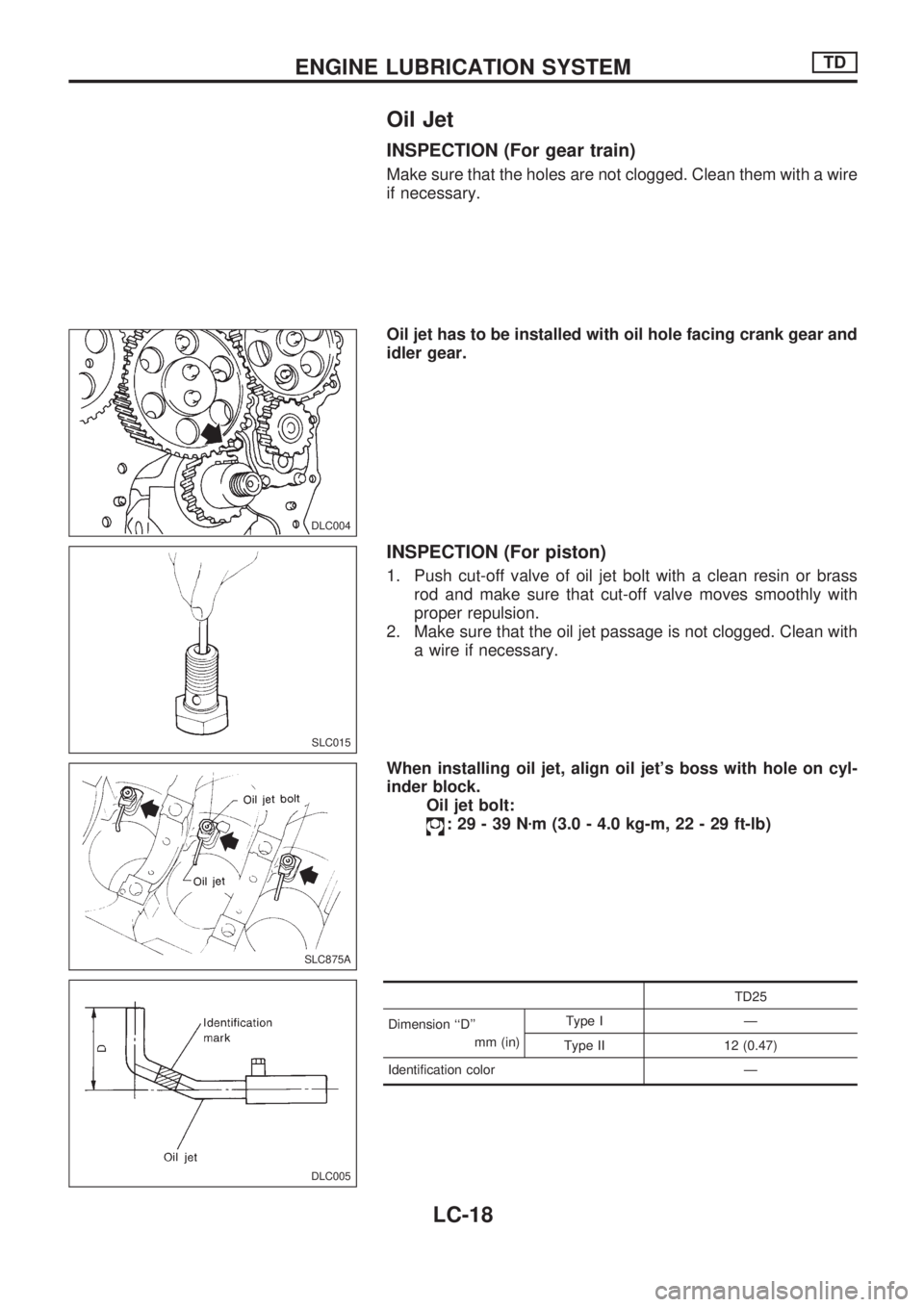

Oil Jet

INSPECTION (For gear train)

Make sure that the holes are not clogged. Clean them with a wire

if necessary.

Oil jet has to be installed with oil hole facing crank gear and

idler gear.

INSPECTION (For piston)

1. Push cut-off valve of oil jet bolt with a clean resin or brass

rod and make sure that cut-off valve moves smoothly with

proper repulsion.

2. Make sure that the oil jet passage is not clogged. Clean with

a wire if necessary.

When installing oil jet, align oil jet's boss with hole on cyl-

inder block.

Oil jet bolt:

:29-39Nzm (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

TD25

Dimension ``D''

mm (in)Type I Ð

Type II 12 (0.47)

Identification color Ð

DLC004

SLC015

SLC875A

DLC005

ENGINE LUBRICATION SYSTEMTD

LC-18

Page 958 of 1659

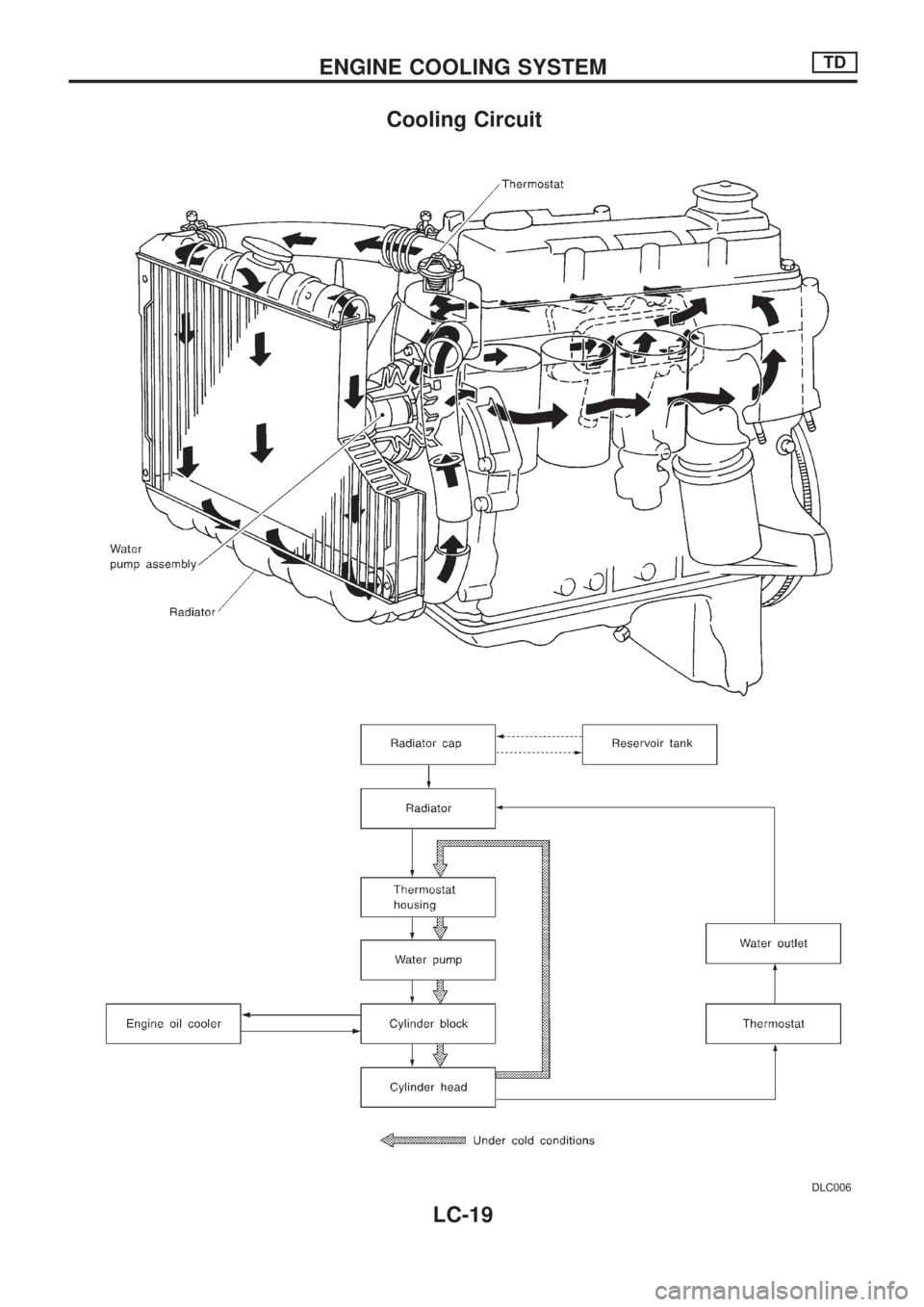

Cooling Circuit

DLC006

ENGINE COOLING SYSTEMTD

LC-19

Page 959 of 1659

Cooling System Inspection

WARNING:

Never remove the radiator cap when the engine is hot; seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around cap and carefully loosen it a quar-

ter turn to release built-up pressure. Then remove the cap

completely.

CHECKING HOSES

Check hoses for proper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

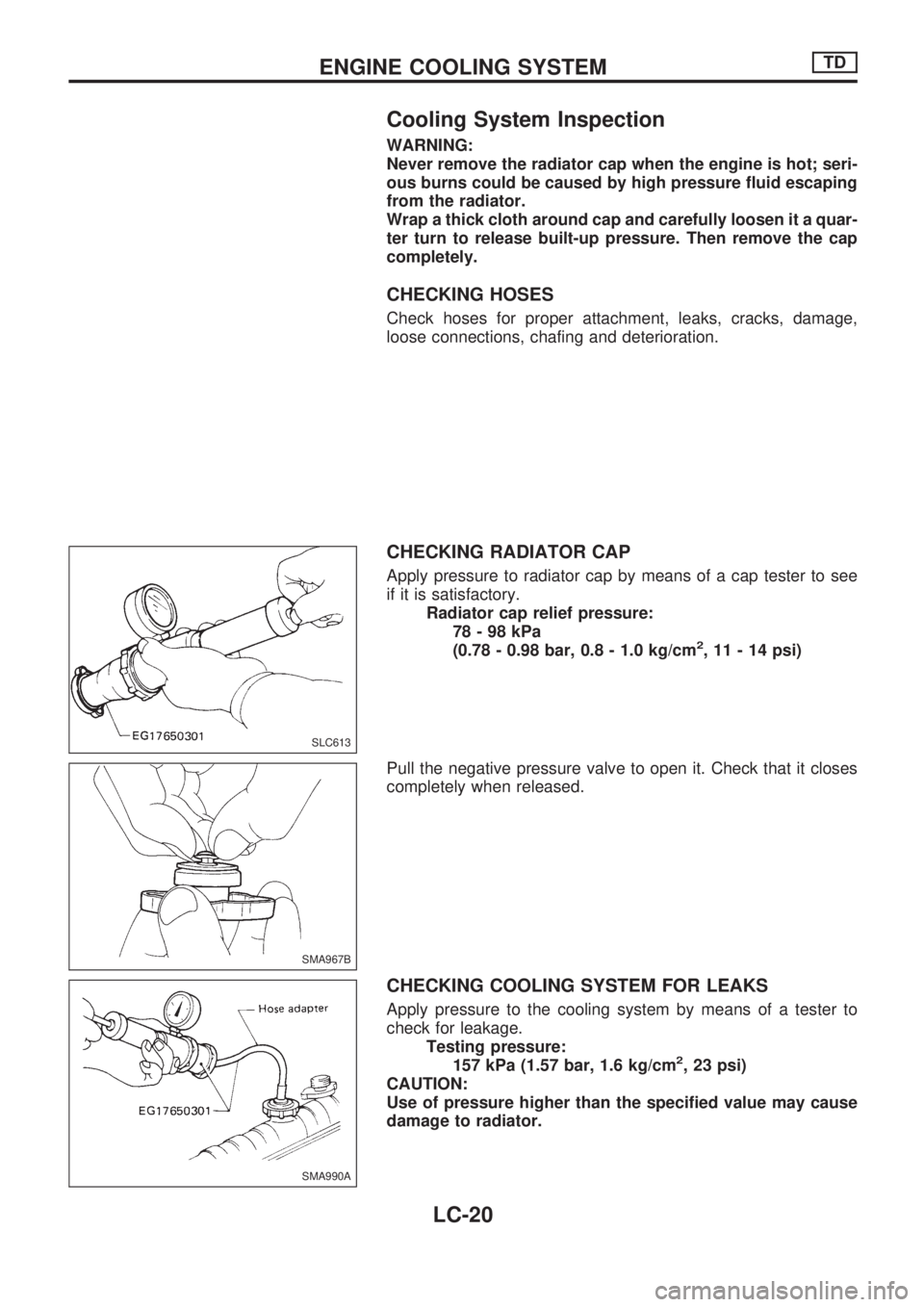

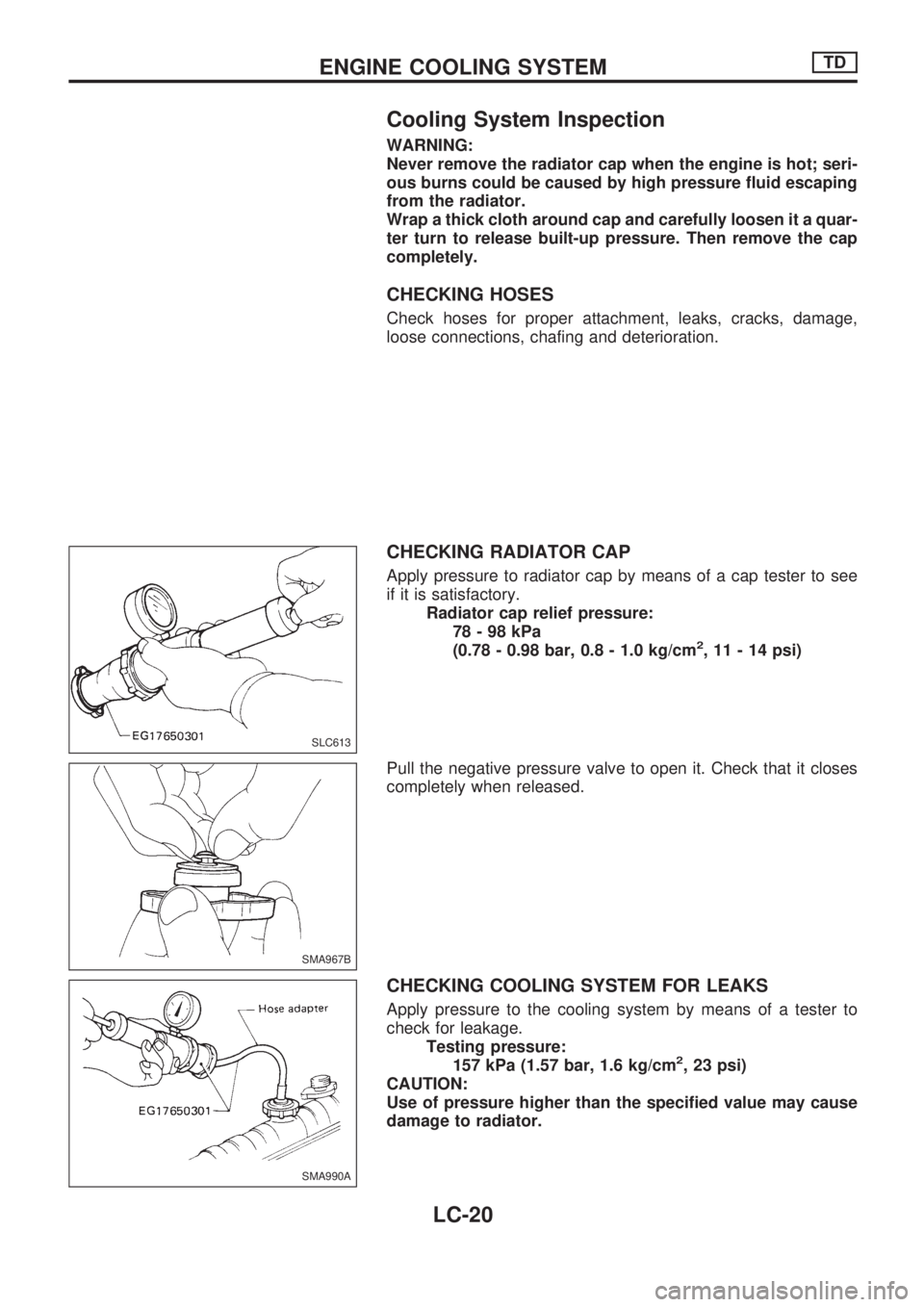

CHECKING RADIATOR CAP

Apply pressure to radiator cap by means of a cap tester to see

if it is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Pull the negative pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system by means of a tester to

check for leakage.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Use of pressure higher than the specified value may cause

damage to radiator.

SLC613

SMA967B

SMA990A

ENGINE COOLING SYSTEMTD

LC-20

Page 960 of 1659

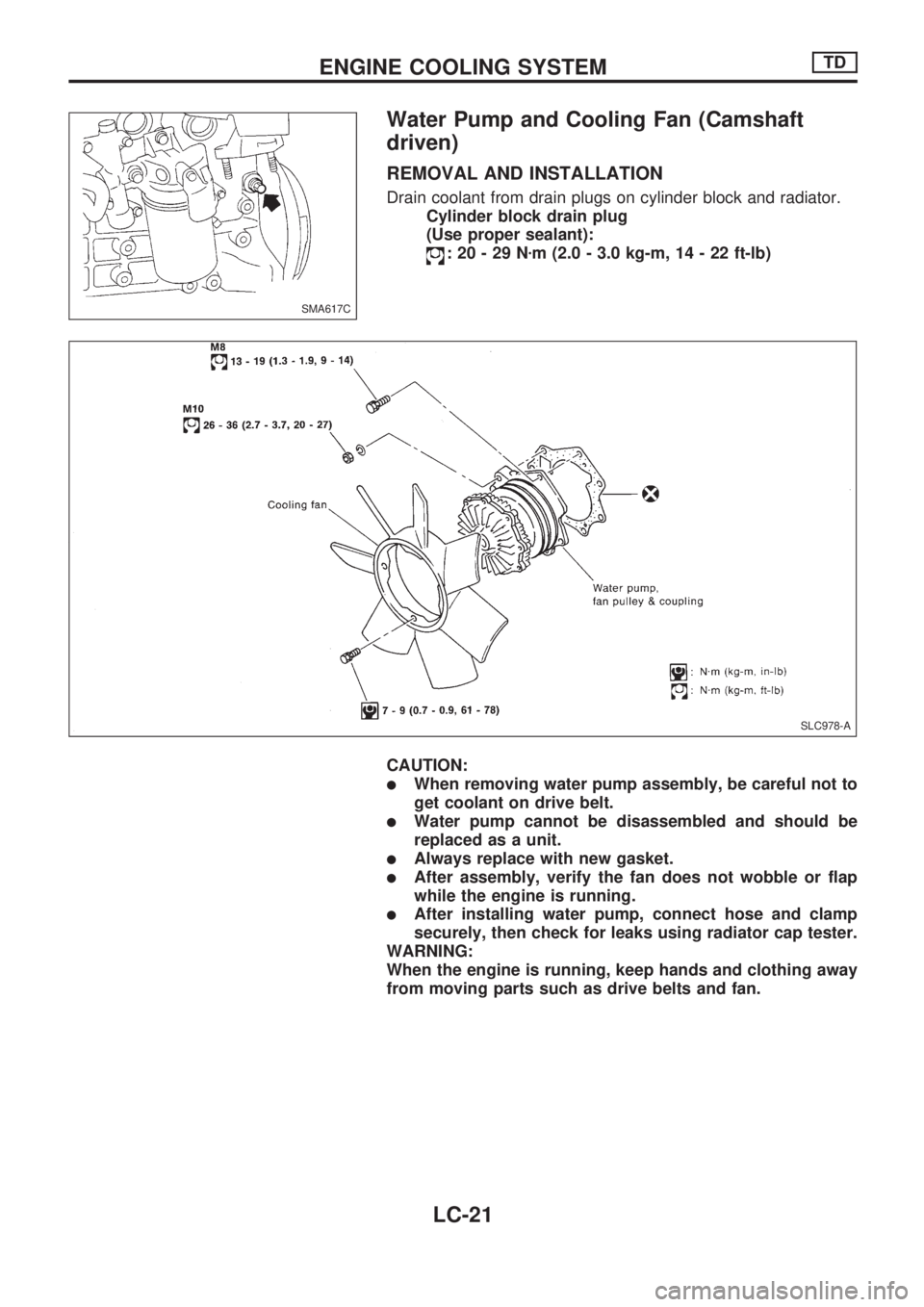

Water Pump and Cooling Fan (Camshaft

driven)

REMOVAL AND INSTALLATION

Drain coolant from drain plugs on cylinder block and radiator.

Cylinder block drain plug

(Use proper sealant):

:20-29Nzm (2.0 - 3.0 kg-m, 14 - 22 ft-lb)

CAUTION:

lWhen removing water pump assembly, be careful not to

get coolant on drive belt.

lWater pump cannot be disassembled and should be

replaced as a unit.

lAlways replace with new gasket.

lAfter assembly, verify the fan does not wobble or flap

while the engine is running.

lAfter installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

WARNING:

When the engine is running, keep hands and clothing away

from moving parts such as drive belts and fan.

SMA617C

SLC978-A

ENGINE COOLING SYSTEMTD

LC-21

Trending: temperature sensor, fuse diagram, mirror, battery location, brake sensor, gas type, 4WD