NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 161 of 1833

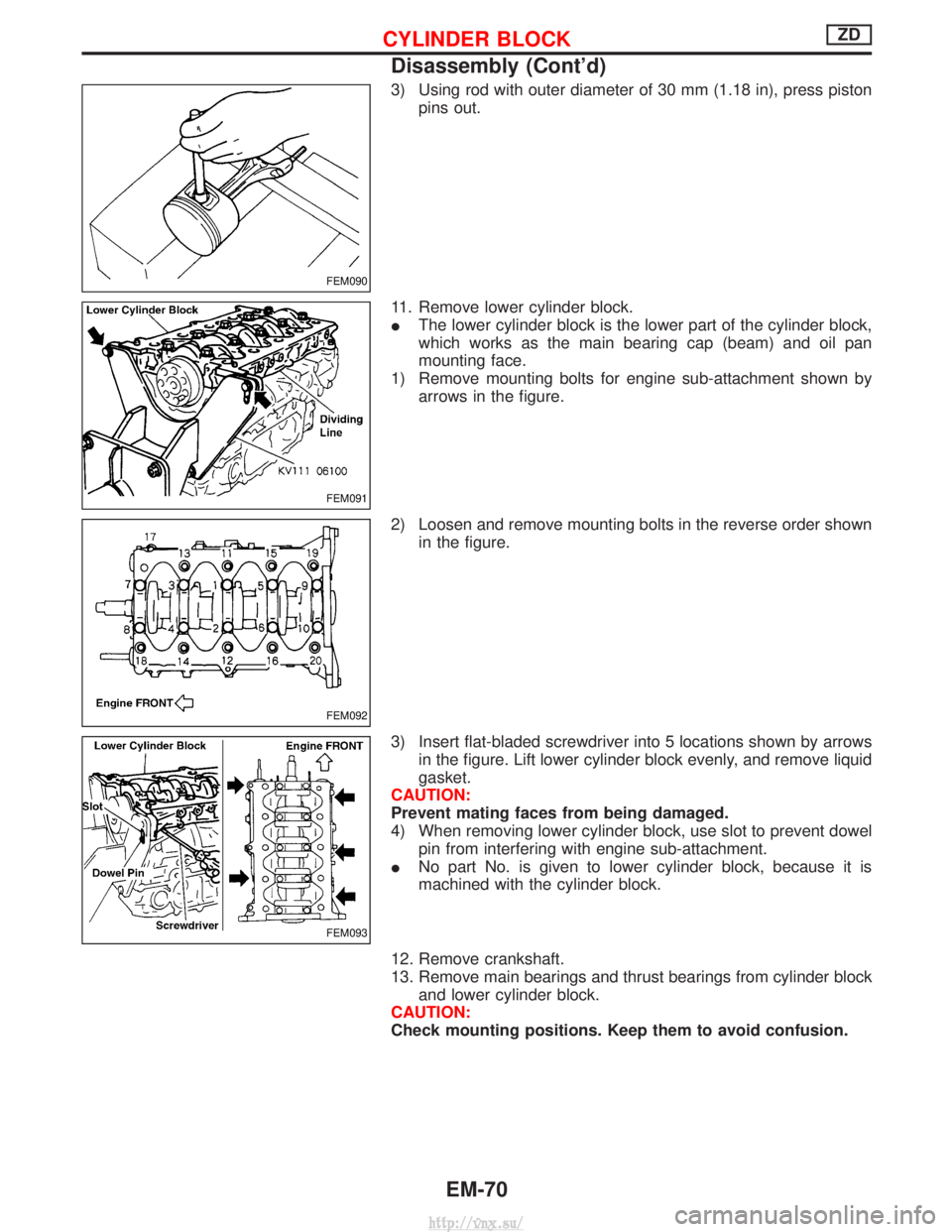

3) Using rod with outer diameter of 30 mm (1.18 in), press pistonpins out.

11. Remove lower cylinder block.

I The lower cylinder block is the lower part of the cylinder block,

which works as the main bearing cap (beam) and oil pan

mounting face.

1) Remove mounting bolts for engine sub-attachment shown by arrows in the figure.

2) Loosen and remove mounting bolts in the reverse order shown in the figure.

3) Insert flat-bladed screwdriver into 5 locations shown by arrows in the figure. Lift lower cylinder block evenly, and remove liquid

gasket.

CAUTION:

Prevent mating faces from being damaged.

4) When removing lower cylinder block, use slot to prevent dowel pin from interfering with engine sub-attachment.

I No part No. is given to lower cylinder block, because it is

machined with the cylinder block.

12. Remove crankshaft.

13. Remove main bearings and thrust bearings from cylinder block and lower cylinder block.

CAUTION:

Check mounting positions. Keep them to avoid confusion.

FEM090

FEM091

FEM092

FEM093

CYLINDER BLOCKZD

Disassembly (Cont'd)

EM-70

http://vnx.su/

Page 162 of 1833

Inspection

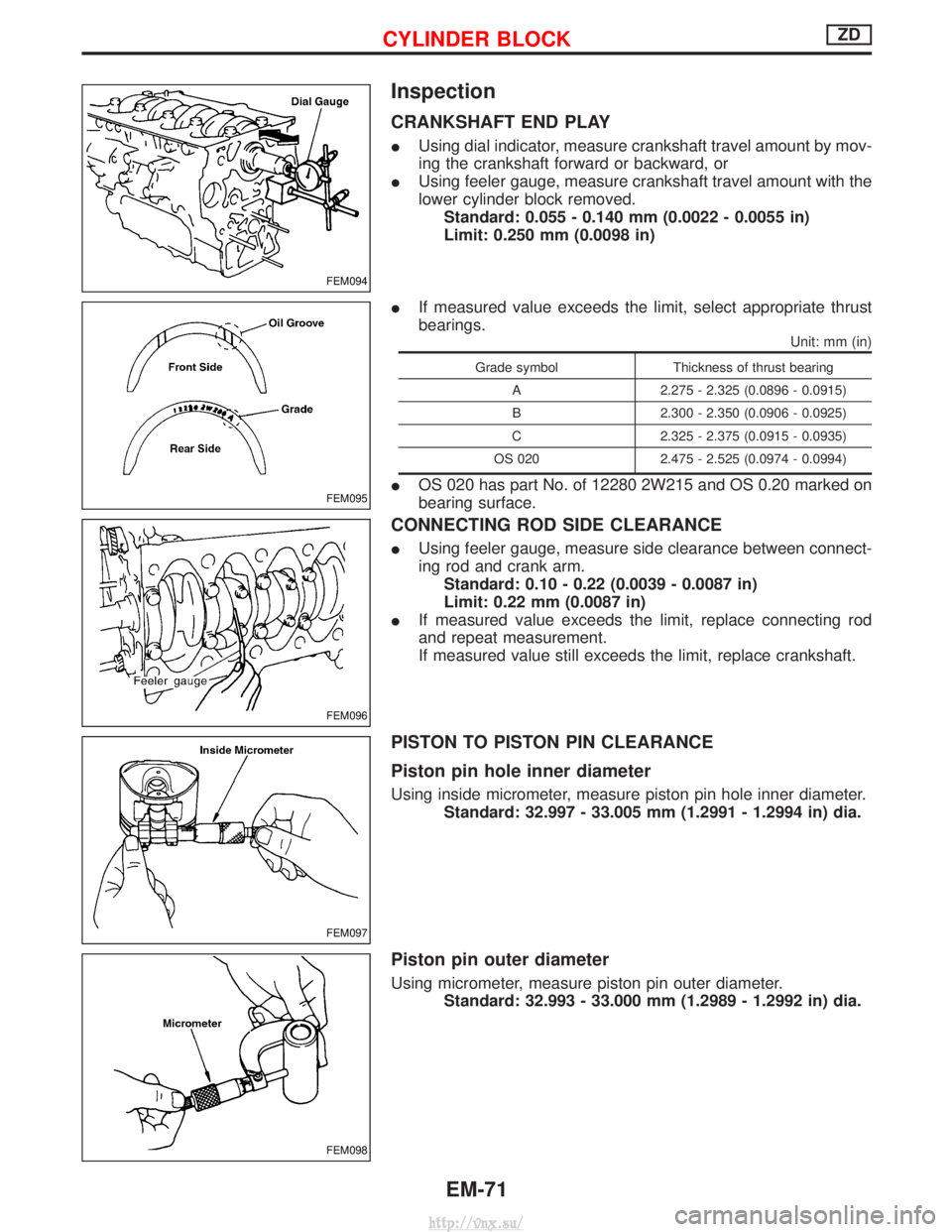

CRANKSHAFT END PLAY

IUsing dial indicator, measure crankshaft travel amount by mov-

ing the crankshaft forward or backward, or

I Using feeler gauge, measure crankshaft travel amount with the

lower cylinder block removed.

Standard: 0.055 - 0.140 mm (0.0022 - 0.0055 in)

Limit: 0.250 mm (0.0098 in)

I If measured value exceeds the limit, select appropriate thrust

bearings.

Unit: mm (in)

Grade symbol Thickness of thrust bearing

A 2.275 - 2.325 (0.0896 - 0.0915)

B 2.300 - 2.350 (0.0906 - 0.0925)

C 2.325 - 2.375 (0.0915 - 0.0935)

OS 020 2.475 - 2.525 (0.0974 - 0.0994)

IOS 020 has part No. of 12280 2W215 and OS 0.20 marked on

bearing surface.

CONNECTING ROD SIDE CLEARANCE

IUsing feeler gauge, measure side clearance between connect-

ing rod and crank arm.

Standard: 0.10 - 0.22 (0.0039 - 0.0087 in)

Limit: 0.22 mm (0.0087 in)

I If measured value exceeds the limit, replace connecting rod

and repeat measurement.

If measured value still exceeds the limit, replace crankshaft.

PISTON TO PISTON PIN CLEARANCE

Piston pin hole inner diameter

Using inside micrometer, measure piston pin hole inner diameter.

Standard: 32.997 - 33.005 mm (1.2991 - 1.2994 in) dia.

Piston pin outer diameter

Using micrometer, measure piston pin outer diameter.Standard: 32.993 - 33.000 mm (1.2989 - 1.2992 in) dia.

FEM094

FEM095

FEM096

FEM097

FEM098

CYLINDER BLOCKZD

EM-71

http://vnx.su/

Page 163 of 1833

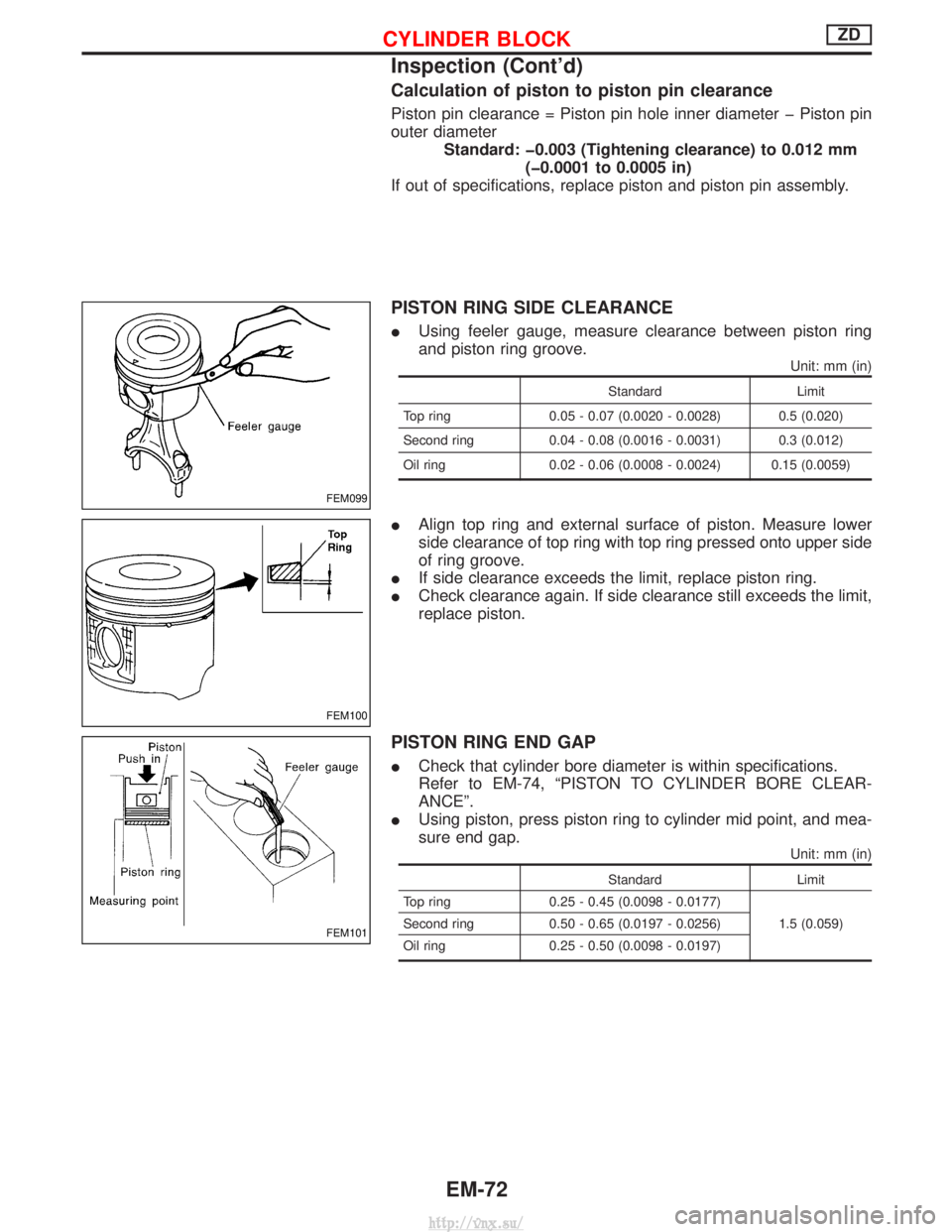

Calculation of piston to piston pin clearance

Piston pin clearance = Piston pin hole inner diameter þ Piston pin

outer diameterStandard: þ0.003 (Tightening clearance) to 0.012 mm (þ0.0001 to 0.0005 in)

If out of specifications, replace piston and piston pin assembly.

PISTON RING SIDE CLEARANCE

I Using feeler gauge, measure clearance between piston ring

and piston ring groove.

Unit: mm (in)

Standard Limit

Top ring 0.05 - 0.07 (0.0020 - 0.0028) 0.5 (0.020)

Second ring 0.04 - 0.08 (0.0016 - 0.0031) 0.3 (0.012)

Oil ring 0.02 - 0.06 (0.0008 - 0.0024) 0.15 (0.0059)

I Align top ring and external surface of piston. Measure lower

side clearance of top ring with top ring pressed onto upper side

of ring groove.

I If side clearance exceeds the limit, replace piston ring.

I Check clearance again. If side clearance still exceeds the limit,

replace piston.

PISTON RING END GAP

ICheck that cylinder bore diameter is within specifications.

Refer to EM-74, ªPISTON TO CYLINDER BORE CLEAR-

ANCEº.

I Using piston, press piston ring to cylinder mid point, and mea-

sure end gap.

Unit: mm (in)

Standard Limit

Top ring 0.25 - 0.45 (0.0098 - 0.0177)

1.5 (0.059)

Second ring 0.50 - 0.65 (0.0197 - 0.0256)

Oil ring 0.25 - 0.50 (0.0098 - 0.0197)

FEM099

FEM100

FEM101

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-72

http://vnx.su/

Page 164 of 1833

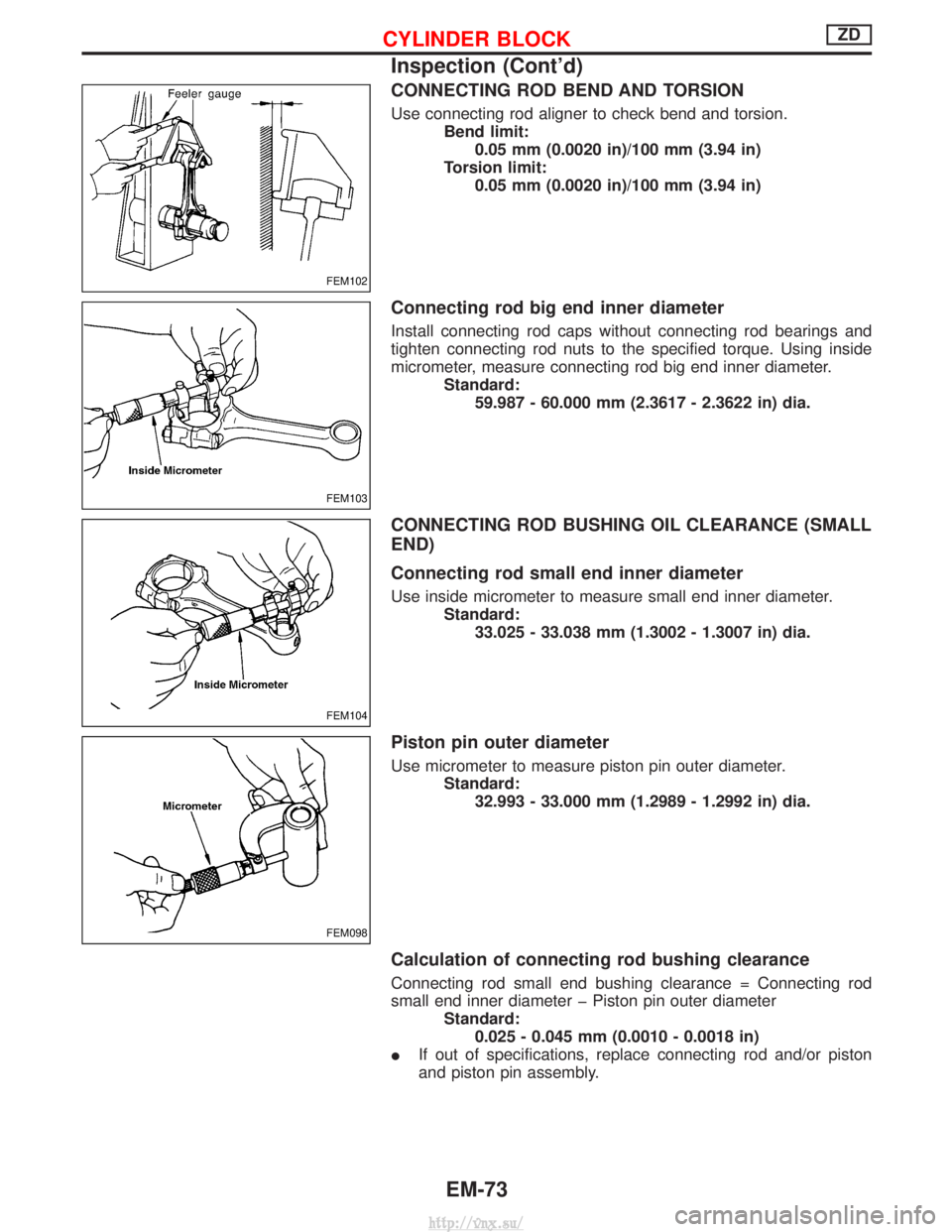

CONNECTING ROD BEND AND TORSION

Use connecting rod aligner to check bend and torsion.Bend limit:0.05 mm (0.0020 in)/100 mm (3.94 in)

Torsion limit: 0.05 mm (0.0020 in)/100 mm (3.94 in)

Connecting rod big end inner diameter

Install connecting rod caps without connecting rod bearings and

tighten connecting rod nuts to the specified torque. Using inside

micrometer, measure connecting rod big end inner diameter. Standard:59.987 - 60.000 mm (2.3617 - 2.3622 in) dia.

CONNECTING ROD BUSHING OIL CLEARANCE (SMALL

END)

Connecting rod small end inner diameter

Use inside micrometer to measure small end inner diameter. Standard:33.025 - 33.038 mm (1.3002 - 1.3007 in) dia.

Piston pin outer diameter

Use micrometer to measure piston pin outer diameter. Standard:32.993 - 33.000 mm (1.2989 - 1.2992 in) dia.

Calculation of connecting rod bushing clearance

Connecting rod small end bushing clearance = Connecting rod

small end inner diameter þ Piston pin outer diameter Standard:0.025 - 0.045 mm (0.0010 - 0.0018 in)

I If out of specifications, replace connecting rod and/or piston

and piston pin assembly.

FEM102

FEM103

FEM104

FEM098

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-73

http://vnx.su/

Page 165 of 1833

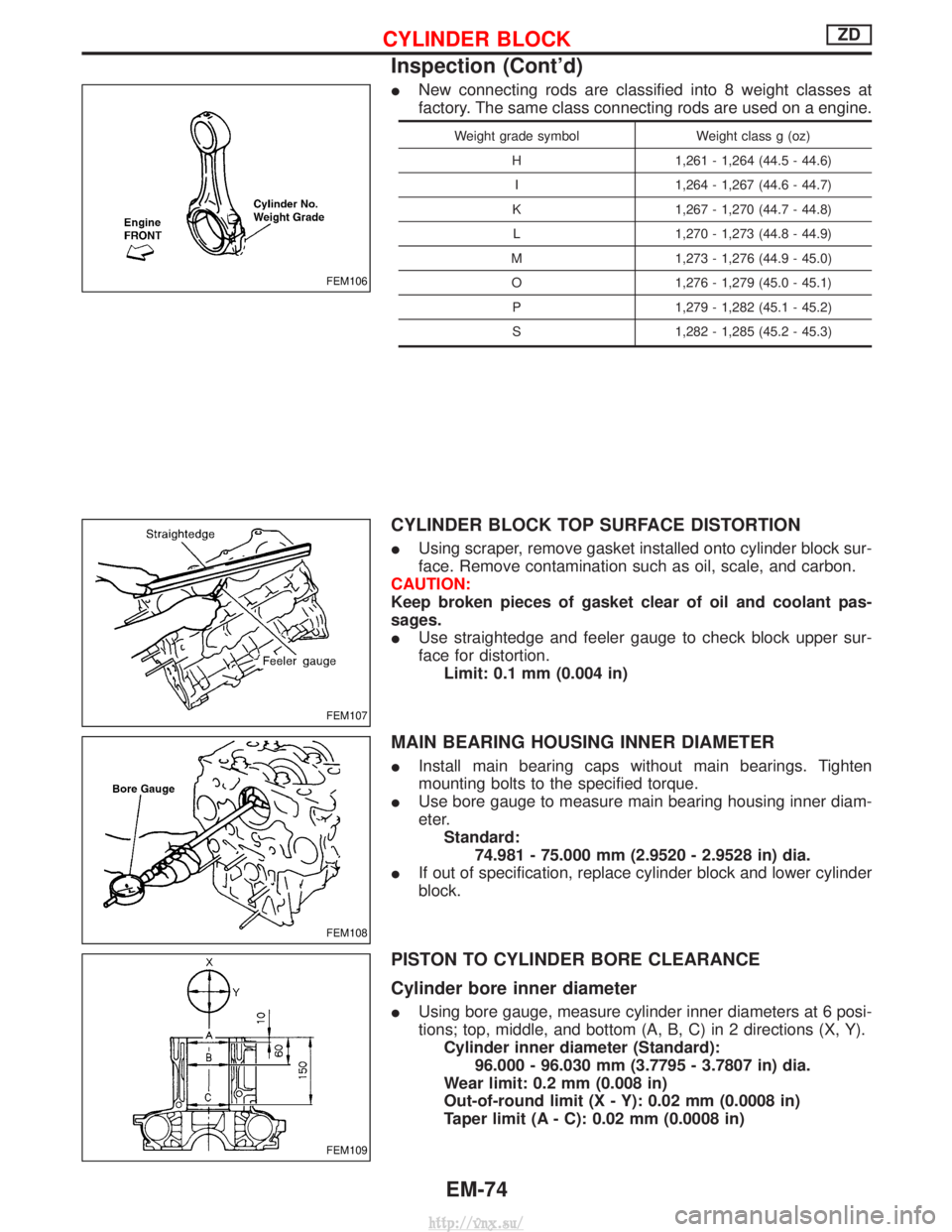

INew connecting rods are classified into 8 weight classes at

factory. The same class connecting rods are used on a engine.

Weight grade symbol Weight class g (oz)

H 1,261 - 1,264 (44.5 - 44.6) I 1,264 - 1,267 (44.6 - 44.7)

K 1,267 - 1,270 (44.7 - 44.8) L 1,270 - 1,273 (44.8 - 44.9)

M 1,273 - 1,276 (44.9 - 45.0) O 1,276 - 1,279 (45.0 - 45.1) P 1,279 - 1,282 (45.1 - 45.2)

S 1,282 - 1,285 (45.2 - 45.3)

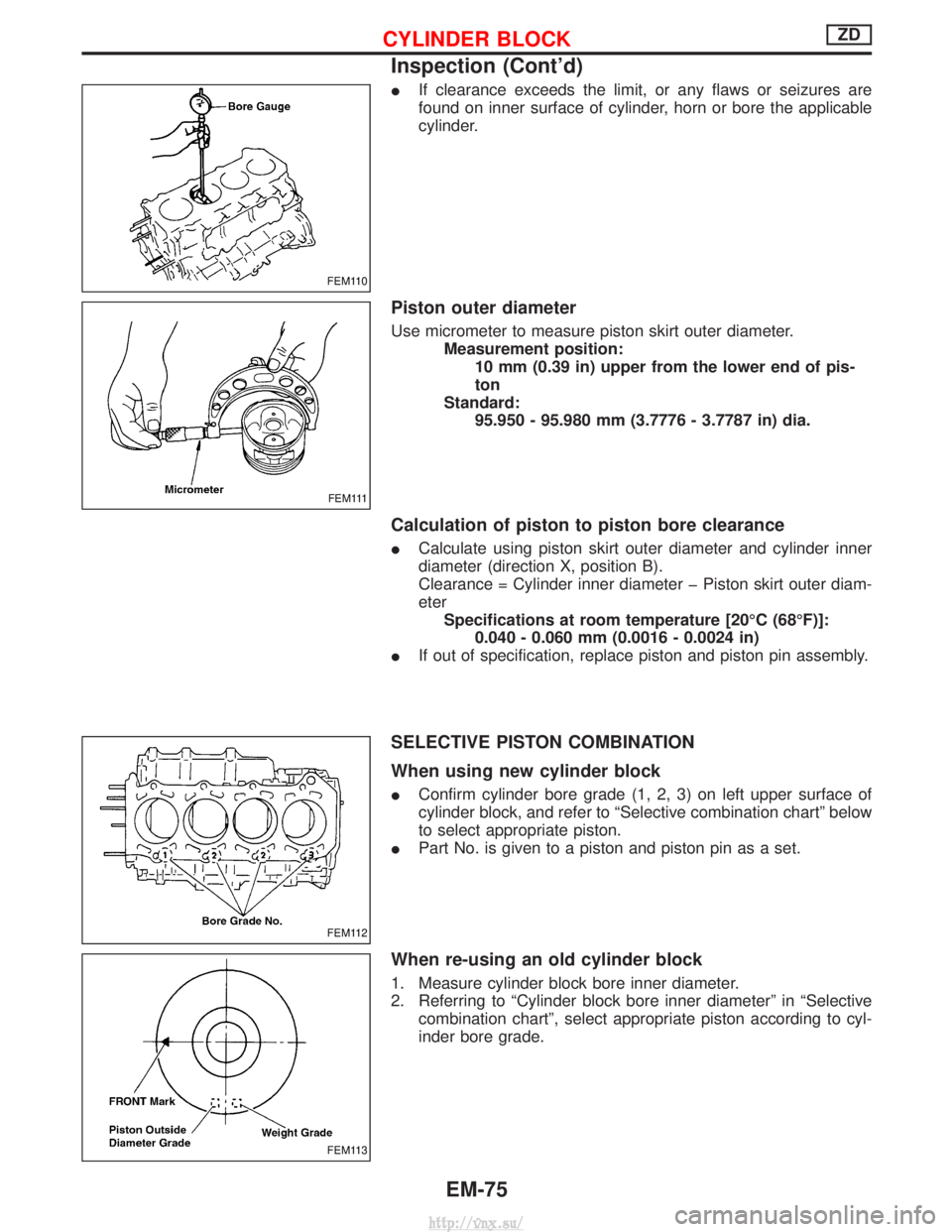

CYLINDER BLOCK TOP SURFACE DISTORTION

I Using scraper, remove gasket installed onto cylinder block sur-

face. Remove contamination such as oil, scale, and carbon.

CAUTION:

Keep broken pieces of gasket clear of oil and coolant pas-

sages.

I Use straightedge and feeler gauge to check block upper sur-

face for distortion.

Limit: 0.1 mm (0.004 in)

MAIN BEARING HOUSING INNER DIAMETER

I Install main bearing caps without main bearings. Tighten

mounting bolts to the specified torque.

I Use bore gauge to measure main bearing housing inner diam-

eter.

Standard: 74.981 - 75.000 mm (2.9520 - 2.9528 in) dia.

I If out of specification, replace cylinder block and lower cylinder

block.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder bore inner diameter

IUsing bore gauge, measure cylinder inner diameters at 6 posi-

tions; top, middle, and bottom (A, B, C) in 2 directions (X, Y).

Cylinder inner diameter (Standard): 96.000 - 96.030 mm (3.7795 - 3.7807 in) dia.

Wear limit: 0.2 mm (0.008 in)

Out-of-round limit (X - Y): 0.02 mm (0.0008 in)

Taper limit (A - C): 0.02 mm (0.0008 in)

FEM106

FEM107

FEM108

FEM109

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-74

http://vnx.su/

Page 166 of 1833

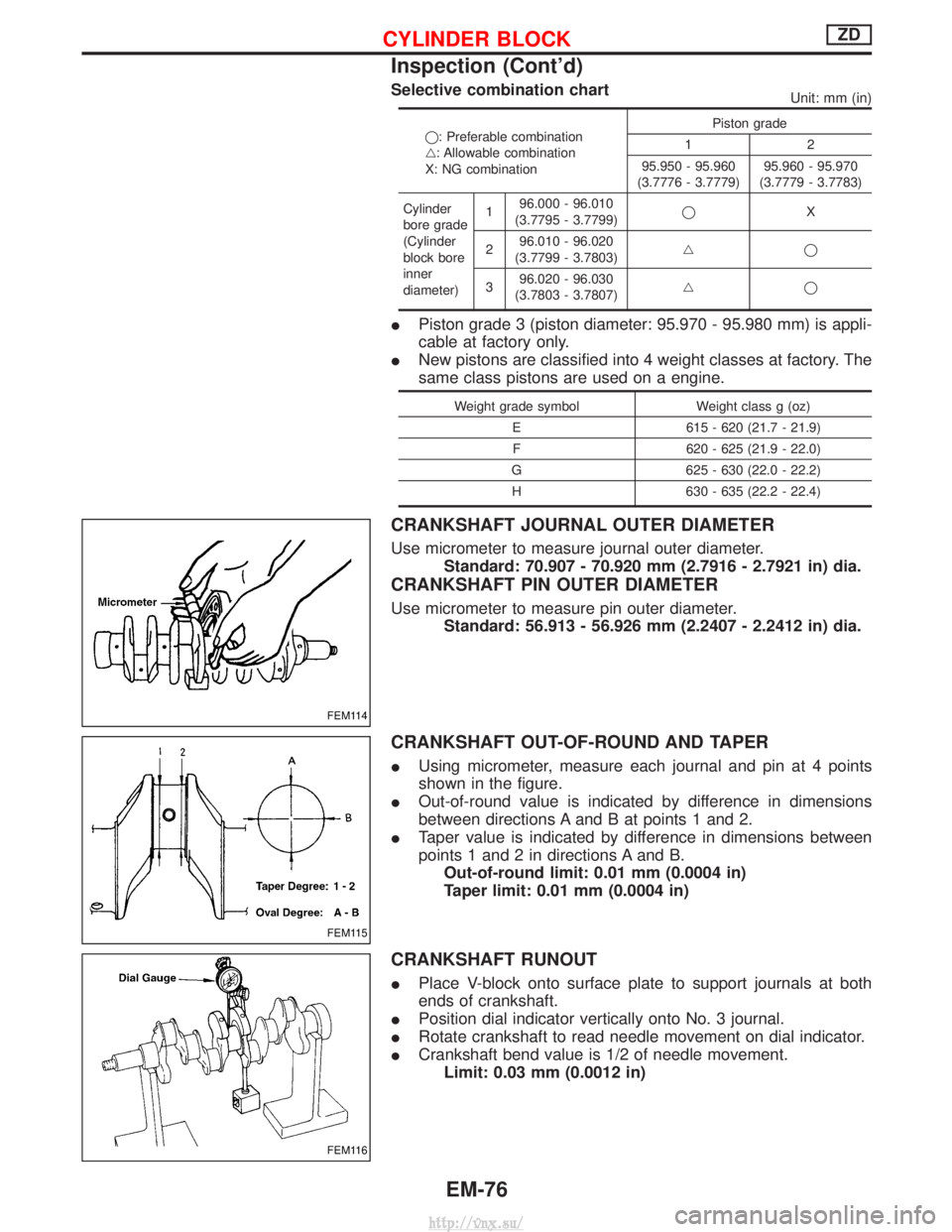

IIf clearance exceeds the limit, or any flaws or seizures are

found on inner surface of cylinder, horn or bore the applicable

cylinder.

Piston outer diameter

Use micrometer to measure piston skirt outer diameter.

Measurement position:10 mm (0.39 in) upper from the lower end of pis-

ton

Standard: 95.950 - 95.980 mm (3.7776 - 3.7787 in) dia.

Calculation of piston to piston bore clearance

ICalculate using piston skirt outer diameter and cylinder inner

diameter (direction X, position B).

Clearance = Cylinder inner diameter þ Piston skirt outer diam-

eter

Specifications at room temperature [20ÉC (68ÉF)]: 0.040 - 0.060 mm (0.0016 - 0.0024 in)

I If out of specification, replace piston and piston pin assembly.

SELECTIVE PISTON COMBINATION

When using new cylinder block

IConfirm cylinder bore grade (1, 2, 3) on left upper surface of

cylinder block, and refer to ªSelective combination chartº below

to select appropriate piston.

I Part No. is given to a piston and piston pin as a set.

When re-using an old cylinder block

1. Measure cylinder block bore inner diameter.

2. Referring to ªCylinder block bore inner diameterº in ªSelective

combination chartº, select appropriate piston according to cyl-

inder bore grade.

FEM110

FEM111

FEM112

FEM113

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-75

http://vnx.su/

Page 167 of 1833

Selective combination chartUnit: mm (in)

q: Preferable combination

g: Allowable combination

X: NG combinationPiston grade

12

95.950 - 95.960

(3.7776 - 3.7779) 95.960 - 95.970

(3.7779 - 3.7783)

Cylinder

bore grade

(Cylinder

block bore

inner

diameter) 1

96.000 - 96.010

(3.7795 - 3.7799) q

X

2 96.010 - 96.020

(3.7799 - 3.7803) gq

3 96.020 - 96.030

(3.7803 - 3.7807) gq

I

Piston grade 3 (piston diameter: 95.970 - 95.980 mm) is appli-

cable at factory only.

I New pistons are classified into 4 weight classes at factory. The

same class pistons are used on a engine.

Weight grade symbol Weight class g (oz)

E 615 - 620 (21.7 - 21.9) F 620 - 625 (21.9 - 22.0)

G 625 - 630 (22.0 - 22.2) H 630 - 635 (22.2 - 22.4)

CRANKSHAFT JOURNAL OUTER DIAMETER

Use micrometer to measure journal outer diameter. Standard: 70.907 - 70.920 mm (2.7916 - 2.7921 in) dia.

CRANKSHAFT PIN OUTER DIAMETER

Use micrometer to measure pin outer diameter.Standard: 56.913 - 56.926 mm (2.2407 - 2.2412 in) dia.

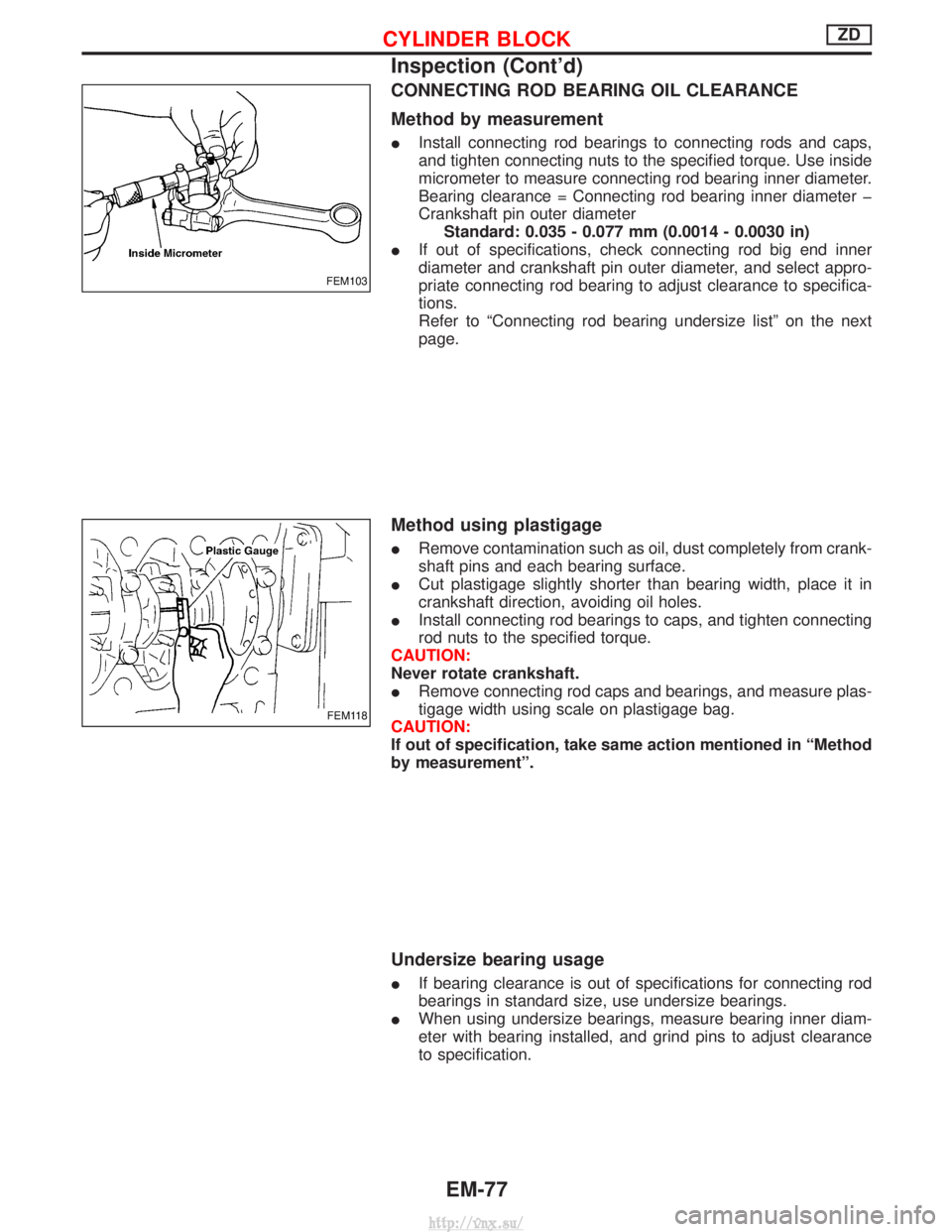

CRANKSHAFT OUT-OF-ROUND AND TAPER

IUsing micrometer, measure each journal and pin at 4 points

shown in the figure.

I Out-of-round value is indicated by difference in dimensions

between directions A and B at points 1 and 2.

I Taper value is indicated by difference in dimensions between

points 1 and 2 in directions A and B.

Out-of-round limit: 0.01 mm (0.0004 in)

Taper limit: 0.01 mm (0.0004 in)

CRANKSHAFT RUNOUT

I Place V-block onto surface plate to support journals at both

ends of crankshaft.

I Position dial indicator vertically onto No. 3 journal.

I Rotate crankshaft to read needle movement on dial indicator.

I Crankshaft bend value is 1/2 of needle movement.

Limit: 0.03 mm (0.0012 in)

FEM114

FEM115

FEM116

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-76

http://vnx.su/

Page 168 of 1833

CONNECTING ROD BEARING OIL CLEARANCE

Method by measurement

IInstall connecting rod bearings to connecting rods and caps,

and tighten connecting nuts to the specified torque. Use inside

micrometer to measure connecting rod bearing inner diameter.

Bearing clearance = Connecting rod bearing inner diameter þ

Crankshaft pin outer diameter

Standard: 0.035 - 0.077 mm (0.0014 - 0.0030 in)

I If out of specifications, check connecting rod big end inner

diameter and crankshaft pin outer diameter, and select appro-

priate connecting rod bearing to adjust clearance to specifica-

tions.

Refer to ªConnecting rod bearing undersize listº on the next

page.

Method using plastigage

IRemove contamination such as oil, dust completely from crank-

shaft pins and each bearing surface.

I Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

I Install connecting rod bearings to caps, and tighten connecting

rod nuts to the specified torque.

CAUTION:

Never rotate crankshaft.

I Remove connecting rod caps and bearings, and measure plas-

tigage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in ªMethod

by measurementº.

Undersize bearing usage

I If bearing clearance is out of specifications for connecting rod

bearings in standard size, use undersize bearings.

I When using undersize bearings, measure bearing inner diam-

eter with bearing installed, and grind pins to adjust clearance

to specification.

FEM103

FEM118

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-77

http://vnx.su/

Page 169 of 1833

Connecting rod bearing undersize list

Unit: mm (in)

SizeThickness

US 0.25 (0.0098) 1.630 - 1.638 (0.0642 - 0.0645)

US 0.50 (0.0197) 1.755 - 1.763 (0.0691 - 0.0694)

US 0.75 (0.0295) 1.880 - 1.888 (0.0740 - 0.0743)

US 1.00 (0.0394) 2.005 - 2.013 (0.0789 - 0.0793)

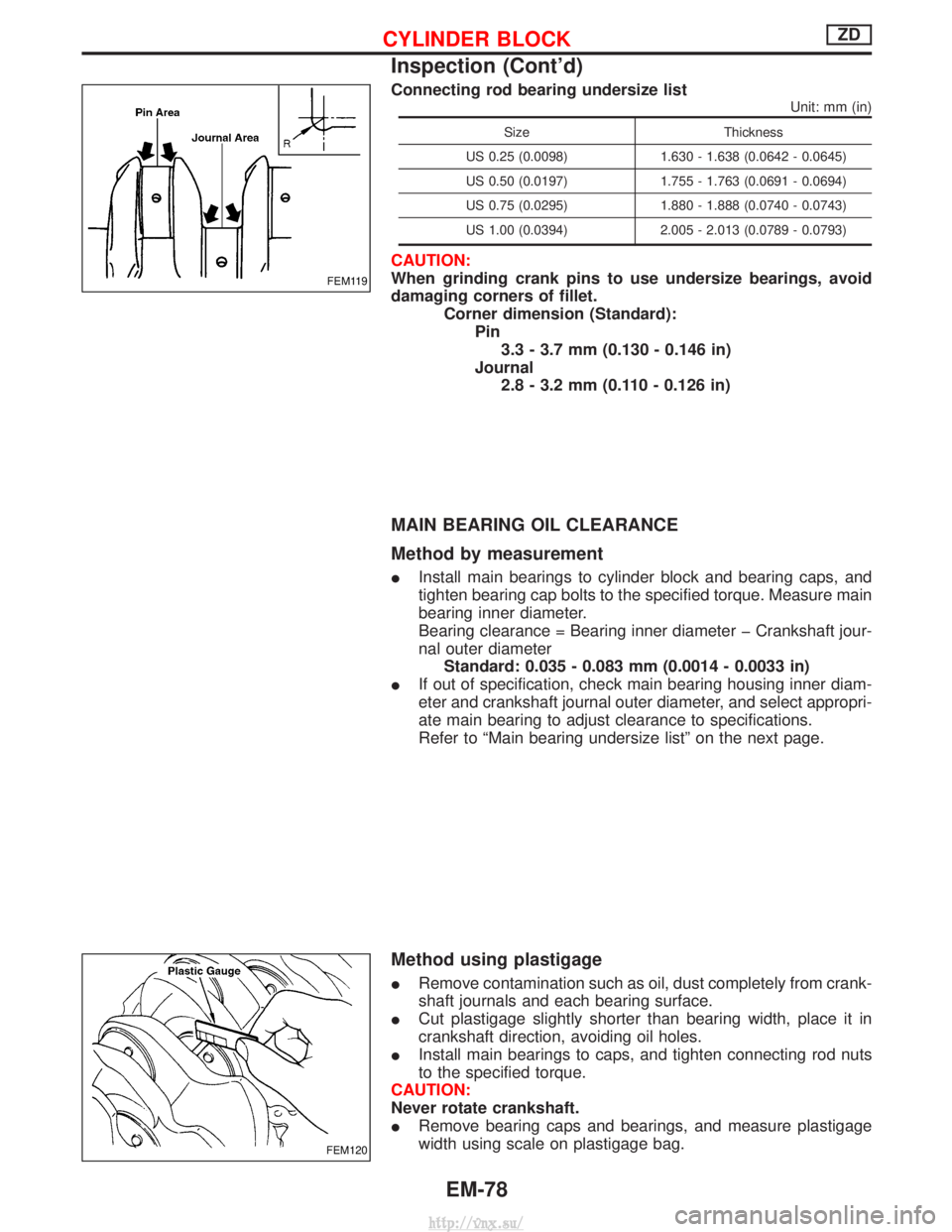

CAUTION:

When grinding crank pins to use undersize bearings, avoid

damaging corners of fillet.

Corner dimension (Standard):Pin3.3 - 3.7 mm (0.130 - 0.146 in)

Journal 2.8 - 3.2 mm (0.110 - 0.126 in)

MAIN BEARING OIL CLEARANCE

Method by measurement

I Install main bearings to cylinder block and bearing caps, and

tighten bearing cap bolts to the specified torque. Measure main

bearing inner diameter.

Bearing clearance = Bearing inner diameter þ Crankshaft jour-

nal outer diameter

Standard: 0.035 - 0.083 mm (0.0014 - 0.0033 in)

I If out of specification, check main bearing housing inner diam-

eter and crankshaft journal outer diameter, and select appropri-

ate main bearing to adjust clearance to specifications.

Refer to ªMain bearing undersize listº on the next page.

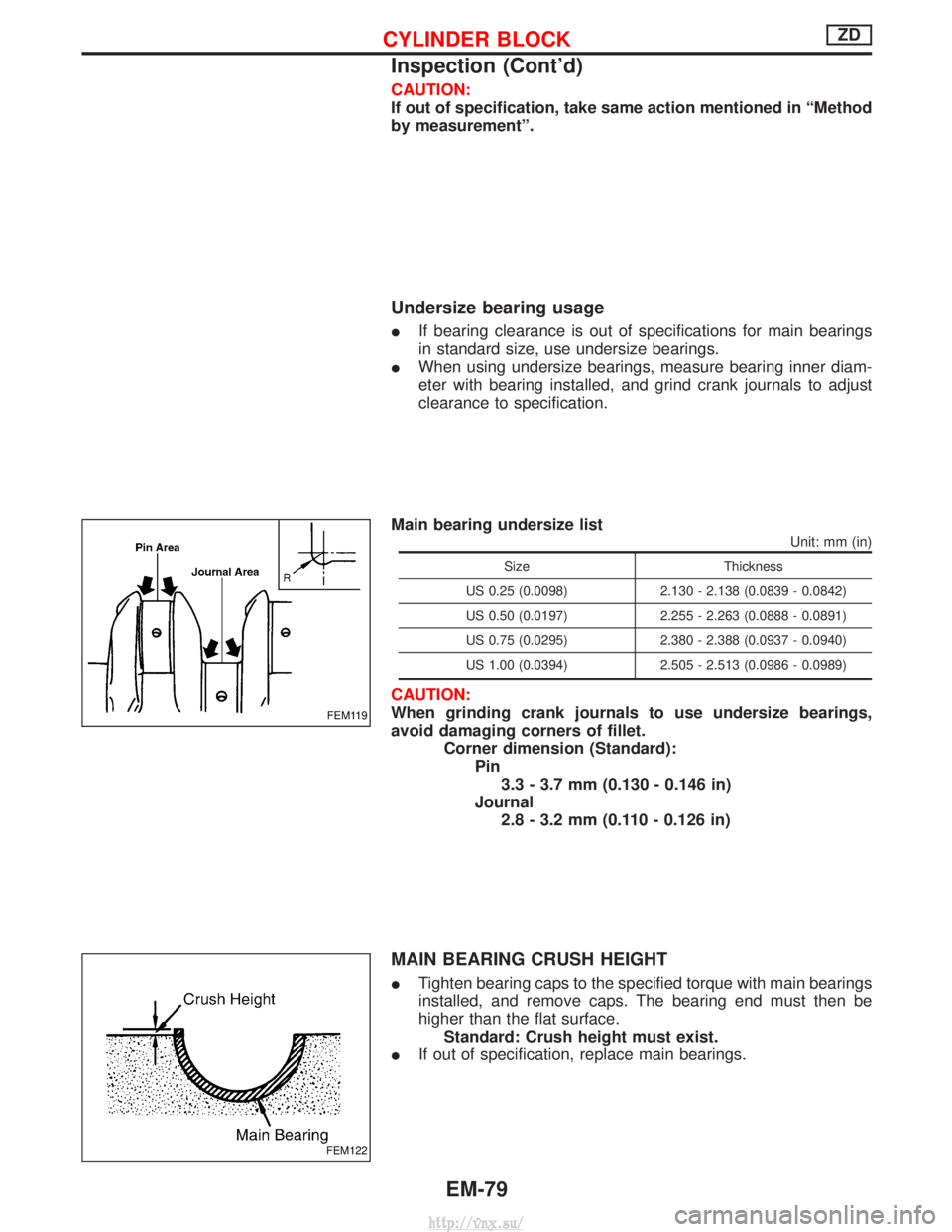

Method using plastigage

IRemove contamination such as oil, dust completely from crank-

shaft journals and each bearing surface.

I Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

I Install main bearings to caps, and tighten connecting rod nuts

to the specified torque.

CAUTION:

Never rotate crankshaft.

I Remove bearing caps and bearings, and measure plastigage

width using scale on plastigage bag.

FEM119

FEM120

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-78

http://vnx.su/

Page 170 of 1833

CAUTION:

If out of specification, take same action mentioned in ªMethod

by measurementº.

Undersize bearing usage

IIf bearing clearance is out of specifications for main bearings

in standard size, use undersize bearings.

I When using undersize bearings, measure bearing inner diam-

eter with bearing installed, and grind crank journals to adjust

clearance to specification.

Main bearing undersize list

Unit: mm (in)

Size Thickness

US 0.25 (0.0098) 2.130 - 2.138 (0.0839 - 0.0842)

US 0.50 (0.0197) 2.255 - 2.263 (0.0888 - 0.0891)

US 0.75 (0.0295) 2.380 - 2.388 (0.0937 - 0.0940)

US 1.00 (0.0394) 2.505 - 2.513 (0.0986 - 0.0989)

CAUTION:

When grinding crank journals to use undersize bearings,

avoid damaging corners of fillet.

Corner dimension (Standard):Pin3.3 - 3.7 mm (0.130 - 0.146 in)

Journal 2.8 - 3.2 mm (0.110 - 0.126 in)

MAIN BEARING CRUSH HEIGHT

I Tighten bearing caps to the specified torque with main bearings

installed, and remove caps. The bearing end must then be

higher than the flat surface.

Standard: Crush height must exist.

I If out of specification, replace main bearings.

FEM119

FEM122

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-79

http://vnx.su/