NISSAN TIIDA 2007 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 471 of 5883

CL-6

< SERVICE INFORMATION >

CLUTCH PEDAL

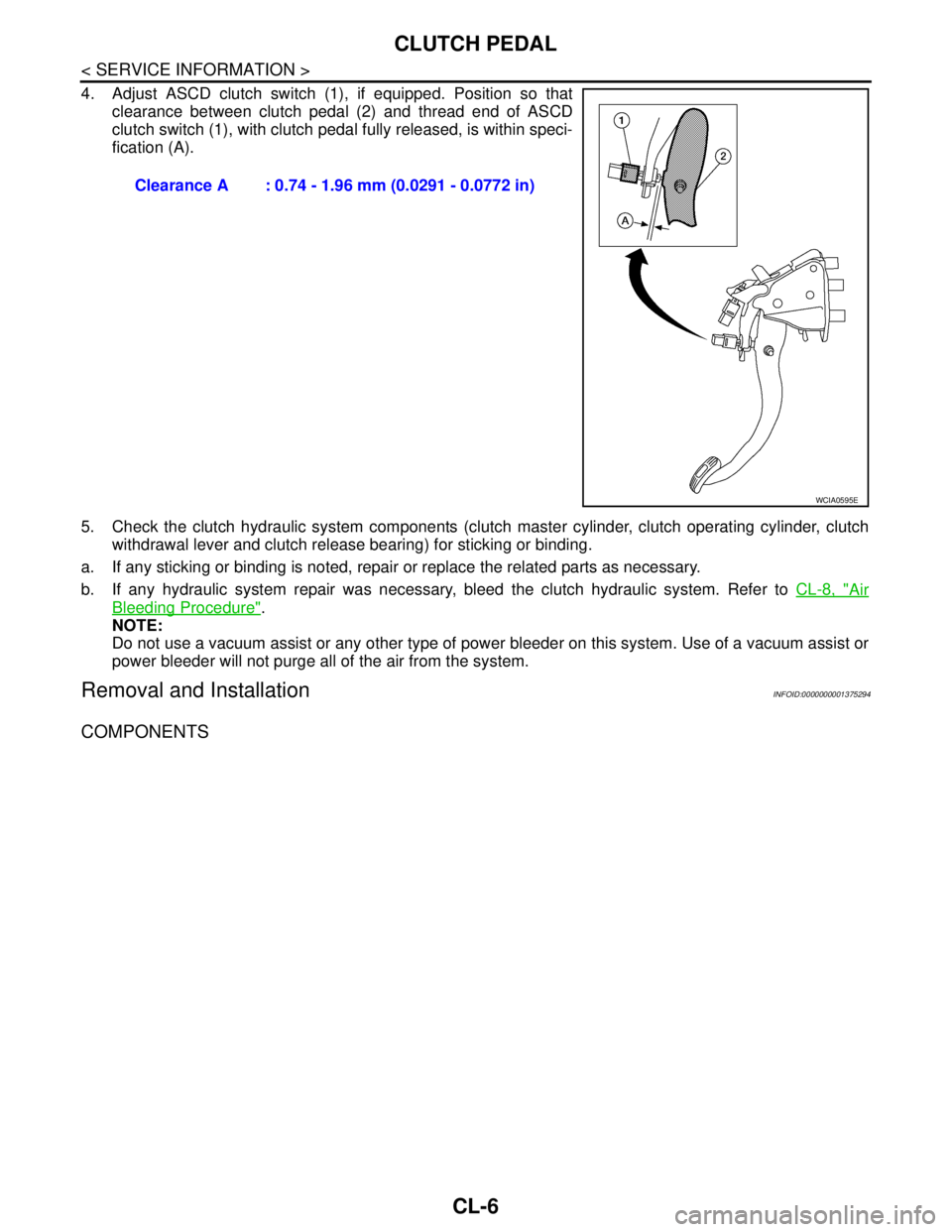

4. Adjust ASCD clutch switch (1), if equipped. Position so that

clearance between clutch pedal (2) and thread end of ASCD

clutch switch (1), with clutch pedal fully released, is within speci-

fication (A).

5. Check the clutch hydraulic system components (clutch master cylinder, clutch operating cylinder, clutch

withdrawal lever and clutch release bearing) for sticking or binding.

a. If any sticking or binding is noted, repair or replace the related parts as necessary.

b. If any hydraulic system repair was necessary, bleed the clutch hydraulic system. Refer to CL-8, "

Air

Bleeding Procedure".

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all of the air from the system.

Removal and InstallationINFOID:0000000001375294

COMPONENTS

Clearance A : 0.74 - 1.96 mm (0.0291 - 0.0772 in)

WCIA0595E

Page 472 of 5883

CLUTCH PEDAL

CL-7

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

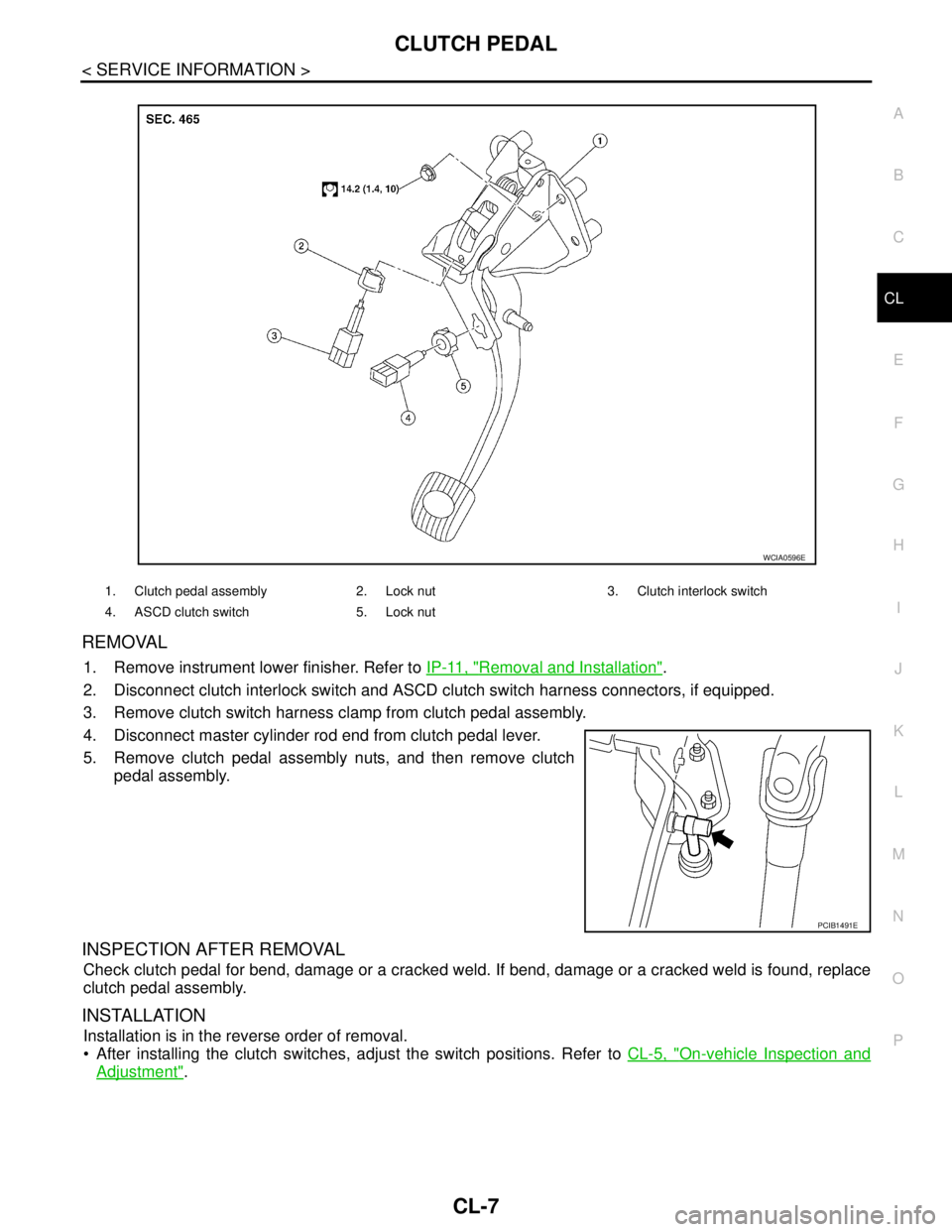

REMOVAL

1. Remove instrument lower finisher. Refer to IP-11, "Removal and Installation".

2. Disconnect clutch interlock switch and ASCD clutch switch harness connectors, if equipped.

3. Remove clutch switch harness clamp from clutch pedal assembly.

4. Disconnect master cylinder rod end from clutch pedal lever.

5. Remove clutch pedal assembly nuts, and then remove clutch

pedal assembly.

INSPECTION AFTER REMOVAL

Check clutch pedal for bend, damage or a cracked weld. If bend, damage or a cracked weld is found, replace

clutch pedal assembly.

INSTALLATION

Installation is in the reverse order of removal.

After installing the clutch switches, adjust the switch positions. Refer to CL-5, "

On-vehicle Inspection and

Adjustment".

1. Clutch pedal assembly 2. Lock nut 3. Clutch interlock switch

4. ASCD clutch switch 5. Lock nut

WCIA0596E

PCIB1491E

Page 473 of 5883

CL-8

< SERVICE INFORMATION >

CLUTCH FLUID

CLUTCH FLUID

Air Bleeding ProcedureINFOID:0000000001375295

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all the air from the system.

CAUTION:

Carefully monitor fluid level in reservoir tank during bleeding operation.

Keep painted surface of body and other parts free of clutch fluid. If it spills, wipe up immediately and

wash the affected area with water.

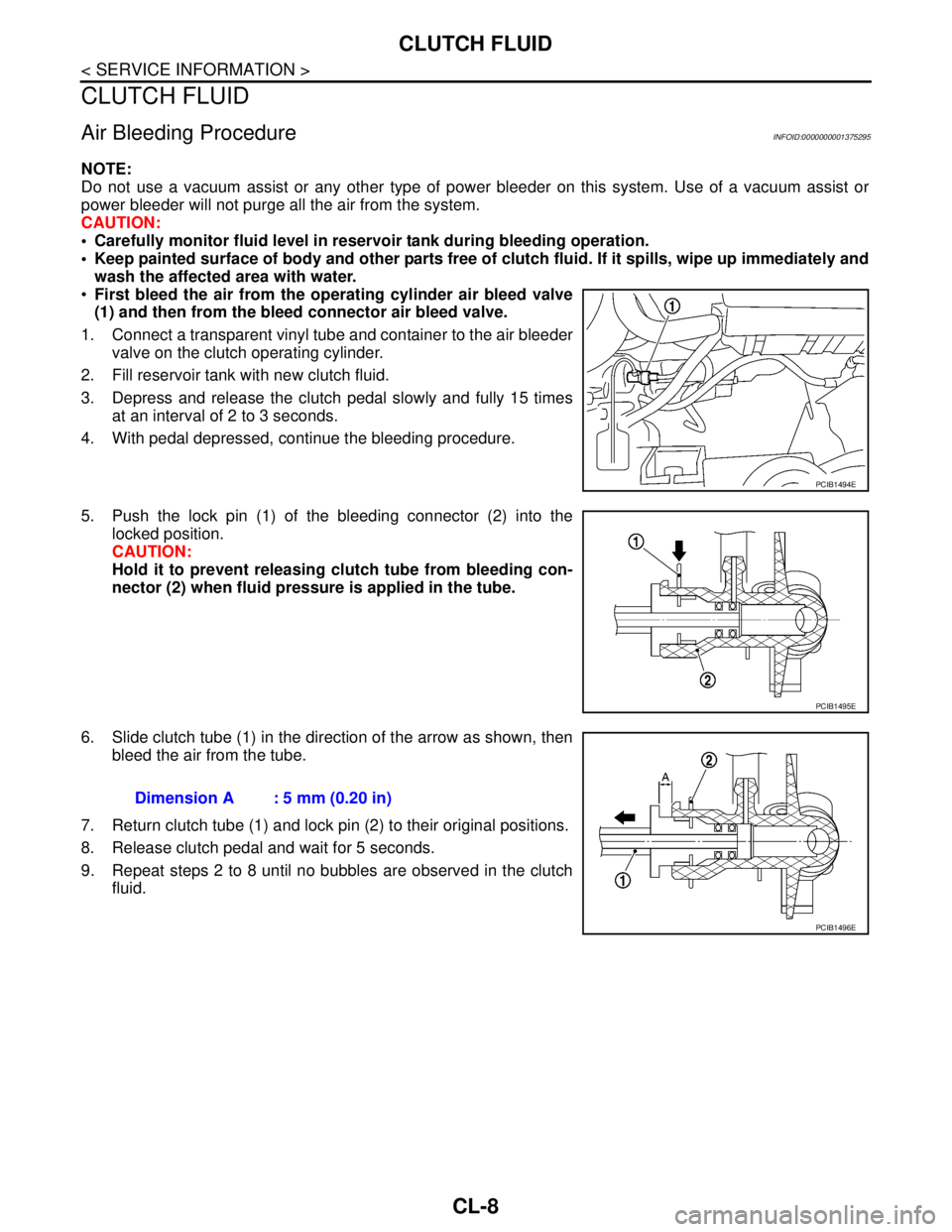

First bleed the air from the operating cylinder air bleed valve

(1) and then from the bleed connector air bleed valve.

1. Connect a transparent vinyl tube and container to the air bleeder

valve on the clutch operating cylinder.

2. Fill reservoir tank with new clutch fluid.

3. Depress and release the clutch pedal slowly and fully 15 times

at an interval of 2 to 3 seconds.

4. With pedal depressed, continue the bleeding procedure.

5. Push the lock pin (1) of the bleeding connector (2) into the

locked position.

CAUTION:

Hold it to prevent releasing clutch tube from bleeding con-

nector (2) when fluid pressure is applied in the tube.

6. Slide clutch tube (1) in the direction of the arrow as shown, then

bleed the air from the tube.

7. Return clutch tube (1) and lock pin (2) to their original positions.

8. Release clutch pedal and wait for 5 seconds.

9. Repeat steps 2 to 8 until no bubbles are observed in the clutch

fluid.

PCIB1494E

PCIB1495E

Dimension A : 5 mm (0.20 in)

PCIB1496E

Page 474 of 5883

CLUTCH MASTER CYLINDER

CL-9

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

CLUTCH MASTER CYLINDER

Removal and InstallationINFOID:0000000001375296

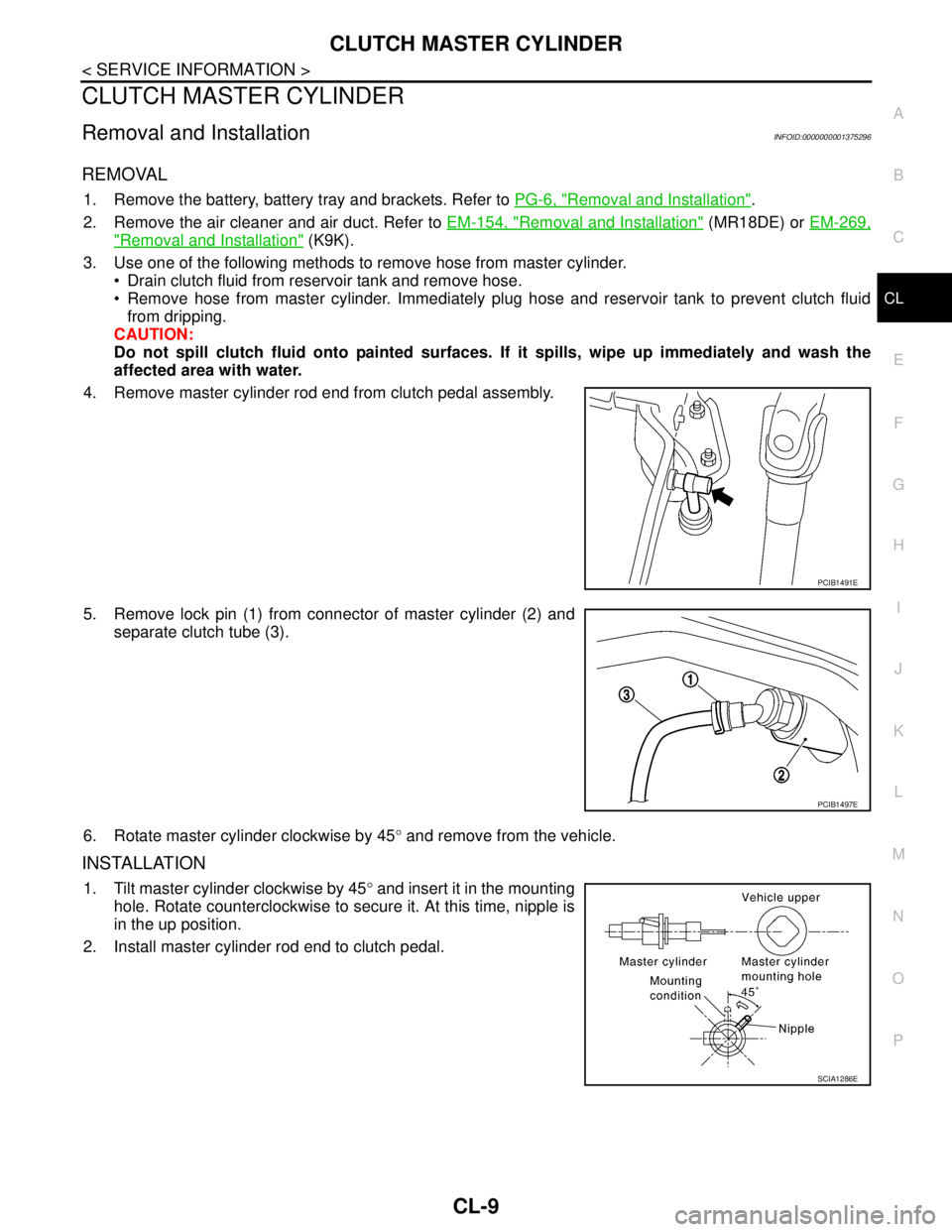

REMOVAL

1. Remove the battery, battery tray and brackets. Refer to PG-6, "Removal and Installation".

2. Remove the air cleaner and air duct. Refer to EM-154, "

Removal and Installation" (MR18DE) or EM-269,

"Removal and Installation" (K9K).

3. Use one of the following methods to remove hose from master cylinder.

Drain clutch fluid from reservoir tank and remove hose.

Remove hose from master cylinder. Immediately plug hose and reservoir tank to prevent clutch fluid

from dripping.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the

affected area with water.

4. Remove master cylinder rod end from clutch pedal assembly.

5. Remove lock pin (1) from connector of master cylinder (2) and

separate clutch tube (3).

6. Rotate master cylinder clockwise by 45° and remove from the vehicle.

INSTALLATION

1. Tilt master cylinder clockwise by 45° and insert it in the mounting

hole. Rotate counterclockwise to secure it. At this time, nipple is

in the up position.

2. Install master cylinder rod end to clutch pedal.

PCIB1491E

PCIB1497E

SCIA1286E

Page 475 of 5883

CL-10

< SERVICE INFORMATION >

CLUTCH MASTER CYLINDER

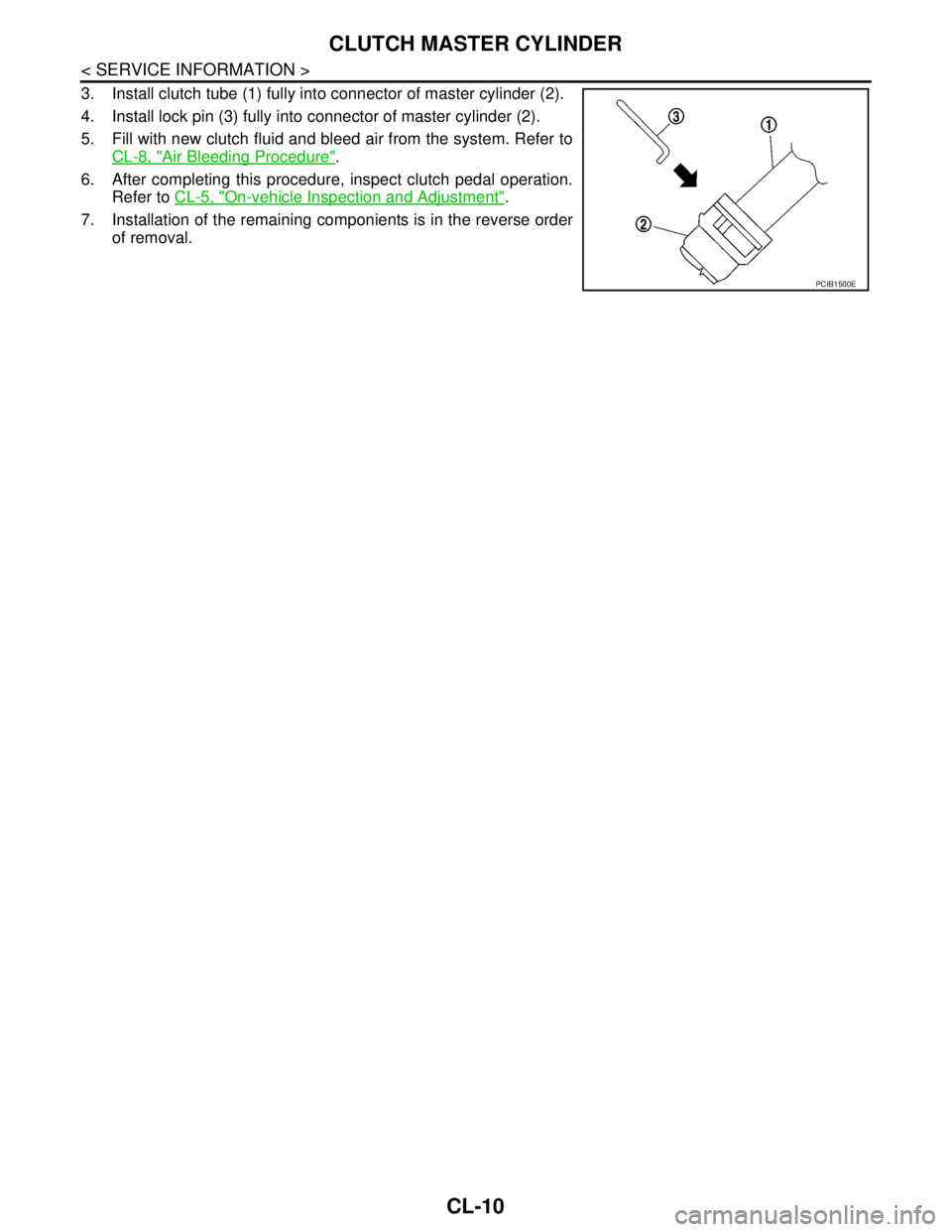

3. Install clutch tube (1) fully into connector of master cylinder (2).

4. Install lock pin (3) fully into connector of master cylinder (2).

5. Fill with new clutch fluid and bleed air from the system. Refer to

CL-8, "

Air Bleeding Procedure".

6. After completing this procedure, inspect clutch pedal operation.

Refer to CL-5, "

On-vehicle Inspection and Adjustment".

7. Installation of the remaining componients is in the reverse order

of removal.

PCIB1500E

Page 476 of 5883

CSC (CONCENTRIC SLAVE CYLINDER)

CL-11

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

CSC (CONCENTRIC SLAVE CYLINDER)

Removal and InstallationINFOID:0000000001375297

CAUTION:

If transaxle assembly is removed from the vehicle, always replace CSC (Concentric slave cylinder).

Return CSC insert to original position to remove transaxle assembly. Dust on clutch disc sliding

parts may damage CSC seal and may cause clutch fluid leakage.

Keep painted surface of the body and other parts free of clutch fluid. If it spills, wipe up immediately

and wash the affected area with water.

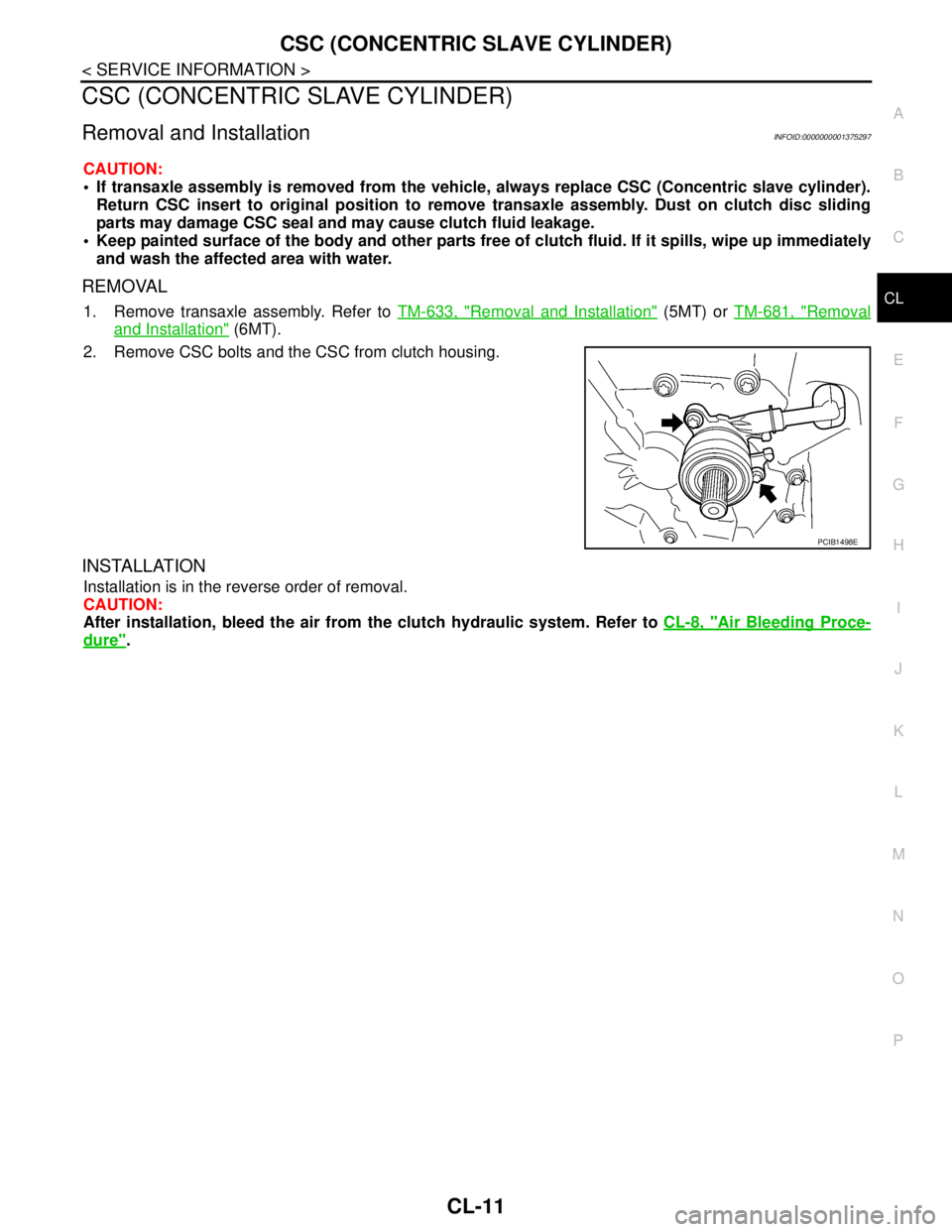

REMOVAL

1. Remove transaxle assembly. Refer to TM-633, "Removal and Installation" (5MT) or TM-681, "Removal

and Installation" (6MT).

2. Remove CSC bolts and the CSC from clutch housing.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, bleed the air from the clutch hydraulic system. Refer to CL-8, "

Air Bleeding Proce-

dure".

PCIB1498E

Page 477 of 5883

CL-12

< SERVICE INFORMATION >

CLUTCH PIPING

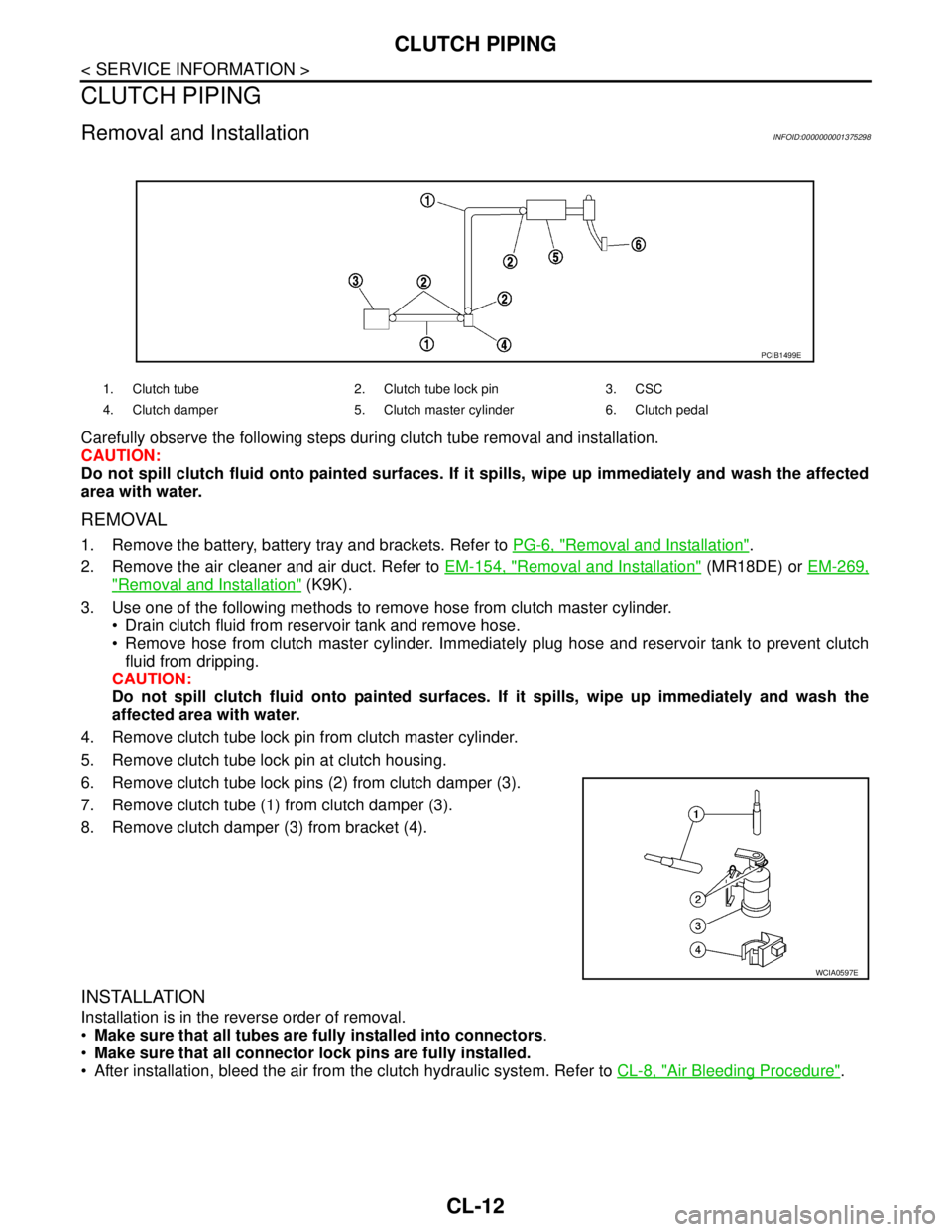

CLUTCH PIPING

Removal and InstallationINFOID:0000000001375298

Carefully observe the following steps during clutch tube removal and installation.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected

area with water.

REMOVAL

1. Remove the battery, battery tray and brackets. Refer to PG-6, "Removal and Installation".

2. Remove the air cleaner and air duct. Refer to EM-154, "

Removal and Installation" (MR18DE) or EM-269,

"Removal and Installation" (K9K).

3. Use one of the following methods to remove hose from clutch master cylinder.

Drain clutch fluid from reservoir tank and remove hose.

Remove hose from clutch master cylinder. Immediately plug hose and reservoir tank to prevent clutch

fluid from dripping.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the

affected area with water.

4. Remove clutch tube lock pin from clutch master cylinder.

5. Remove clutch tube lock pin at clutch housing.

6. Remove clutch tube lock pins (2) from clutch damper (3).

7. Remove clutch tube (1) from clutch damper (3).

8. Remove clutch damper (3) from bracket (4).

INSTALLATION

Installation is in the reverse order of removal.

Make sure that all tubes are fully installed into connectors.

Make sure that all connector lock pins are fully installed.

After installation, bleed the air from the clutch hydraulic system. Refer to CL-8, "

Air Bleeding Procedure".

1. Clutch tube 2. Clutch tube lock pin 3. CSC

4. Clutch damper 5. Clutch master cylinder 6. Clutch pedal

PCIB1499E

WCIA0597E

Page 478 of 5883

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

CL-13

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

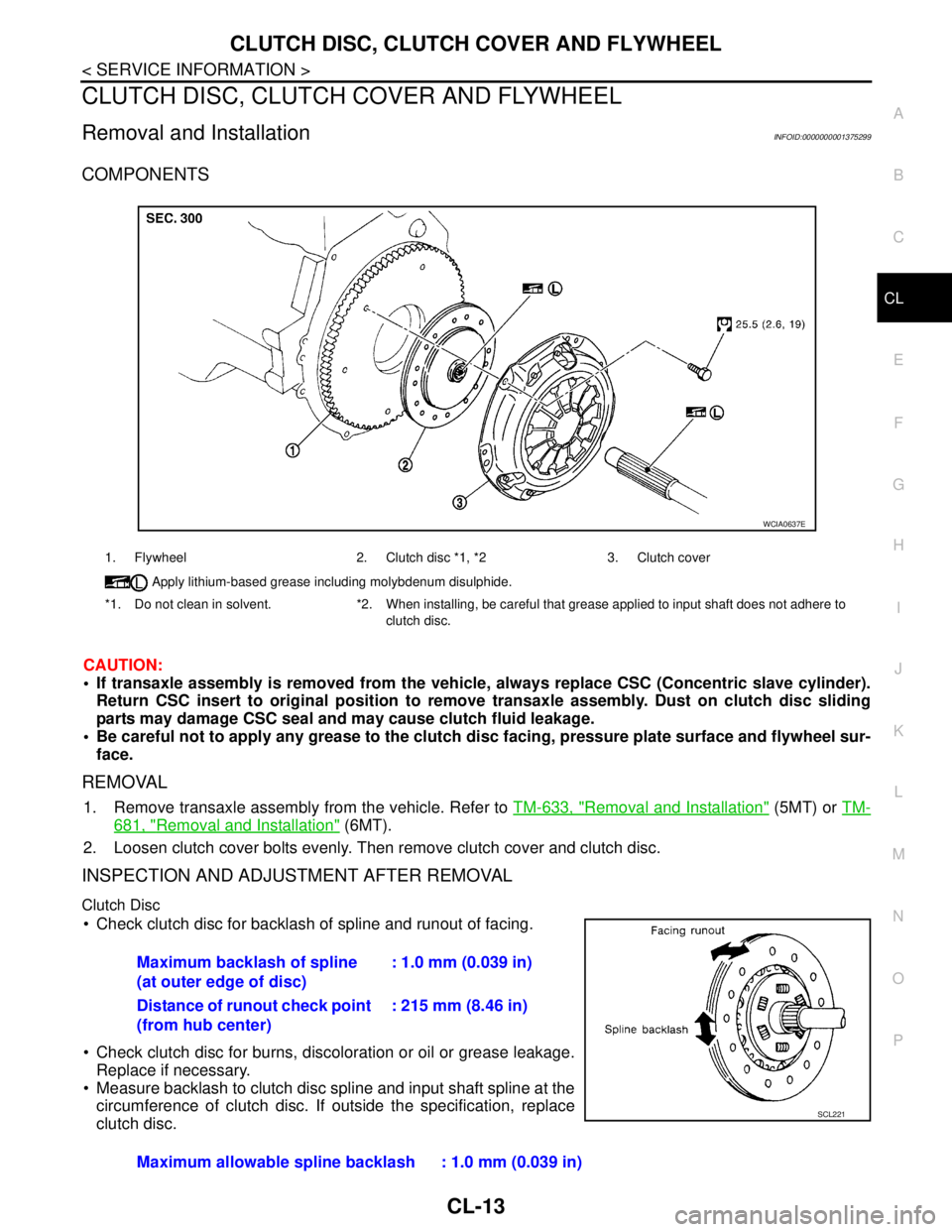

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Removal and InstallationINFOID:0000000001375299

COMPONENTS

CAUTION:

If transaxle assembly is removed from the vehicle, always replace CSC (Concentric slave cylinder).

Return CSC insert to original position to remove transaxle assembly. Dust on clutch disc sliding

parts may damage CSC seal and may cause clutch fluid leakage.

Be careful not to apply any grease to the clutch disc facing, pressure plate surface and flywheel sur-

face.

REMOVAL

1. Remove transaxle assembly from the vehicle. Refer to TM-633, "Removal and Installation" (5MT) or TM-

681, "Removal and Installation" (6MT).

2. Loosen clutch cover bolts evenly. Then remove clutch cover and clutch disc.

INSPECTION AND ADJUSTMENT AFTER REMOVAL

Clutch Disc

Check clutch disc for backlash of spline and runout of facing.

Check clutch disc for burns, discoloration or oil or grease leakage.

Replace if necessary.

Measure backlash to clutch disc spline and input shaft spline at the

circumference of clutch disc. If outside the specification, replace

clutch disc.

1. Flywheel 2. Clutch disc *1, *2 3. Clutch cover

Apply lithium-based grease including molybdenum disulphide.

*1. Do not clean in solvent. *2. When installing, be careful that grease applied to input shaft does not adhere to

clutch disc.

WCIA0637E

Maximum backlash of spline

(at outer edge of disc): 1.0 mm (0.039 in)

Distance of runout check point

(from hub center): 215 mm (8.46 in)

Maximum allowable spline backlash : 1.0 mm (0.039 in)

SCL221

Page 479 of 5883

CL-14

< SERVICE INFORMATION >

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

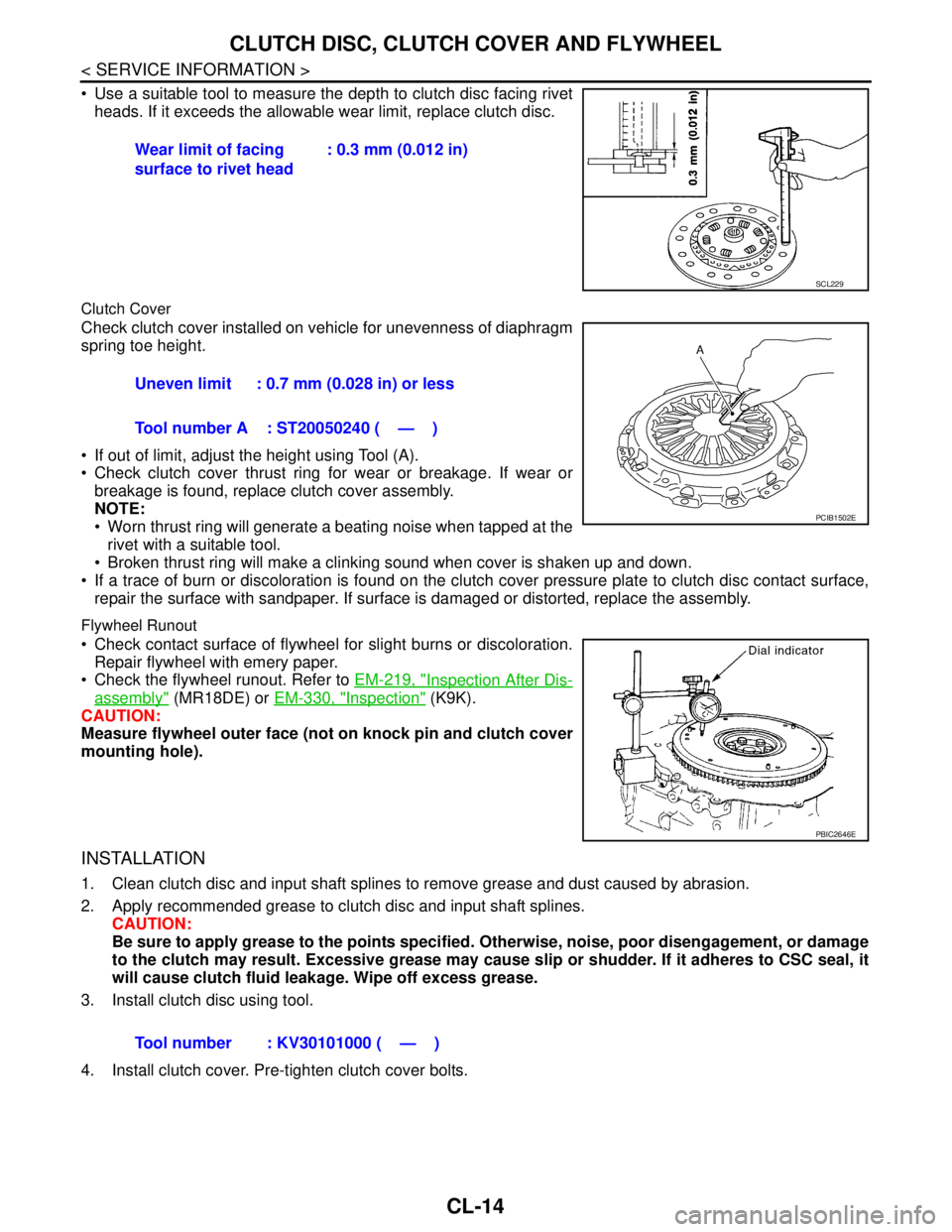

Use a suitable tool to measure the depth to clutch disc facing rivet

heads. If it exceeds the allowable wear limit, replace clutch disc.

Clutch Cover

Check clutch cover installed on vehicle for unevenness of diaphragm

spring toe height.

If out of limit, adjust the height using Tool (A).

Check clutch cover thrust ring for wear or breakage. If wear or

breakage is found, replace clutch cover assembly.

NOTE:

Worn thrust ring will generate a beating noise when tapped at the

rivet with a suitable tool.

Broken thrust ring will make a clinking sound when cover is shaken up and down.

If a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disc contact surface,

repair the surface with sandpaper. If surface is damaged or distorted, replace the assembly.

Flywheel Runout

Check contact surface of flywheel for slight burns or discoloration.

Repair flywheel with emery paper.

Check the flywheel runout. Refer to EM-219, "

Inspection After Dis-

assembly" (MR18DE) or EM-330, "Inspection" (K9K).

CAUTION:

Measure flywheel outer face (not on knock pin and clutch cover

mounting hole).

INSTALLATION

1. Clean clutch disc and input shaft splines to remove grease and dust caused by abrasion.

2. Apply recommended grease to clutch disc and input shaft splines.

CAUTION:

Be sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage

to the clutch may result. Excessive grease may cause slip or shudder. If it adheres to CSC seal, it

will cause clutch fluid leakage. Wipe off excess grease.

3. Install clutch disc using tool.

4. Install clutch cover. Pre-tighten clutch cover bolts.Wear limit of facing

surface to rivet head: 0.3 mm (0.012 in)

SCL229

Uneven limit : 0.7 mm (0.028 in) or less

Tool number A : ST20050240 ( — )

PCIB1502E

PBIC2646E

Tool number : KV30101000 ( — )

Page 480 of 5883

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

CL-15

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

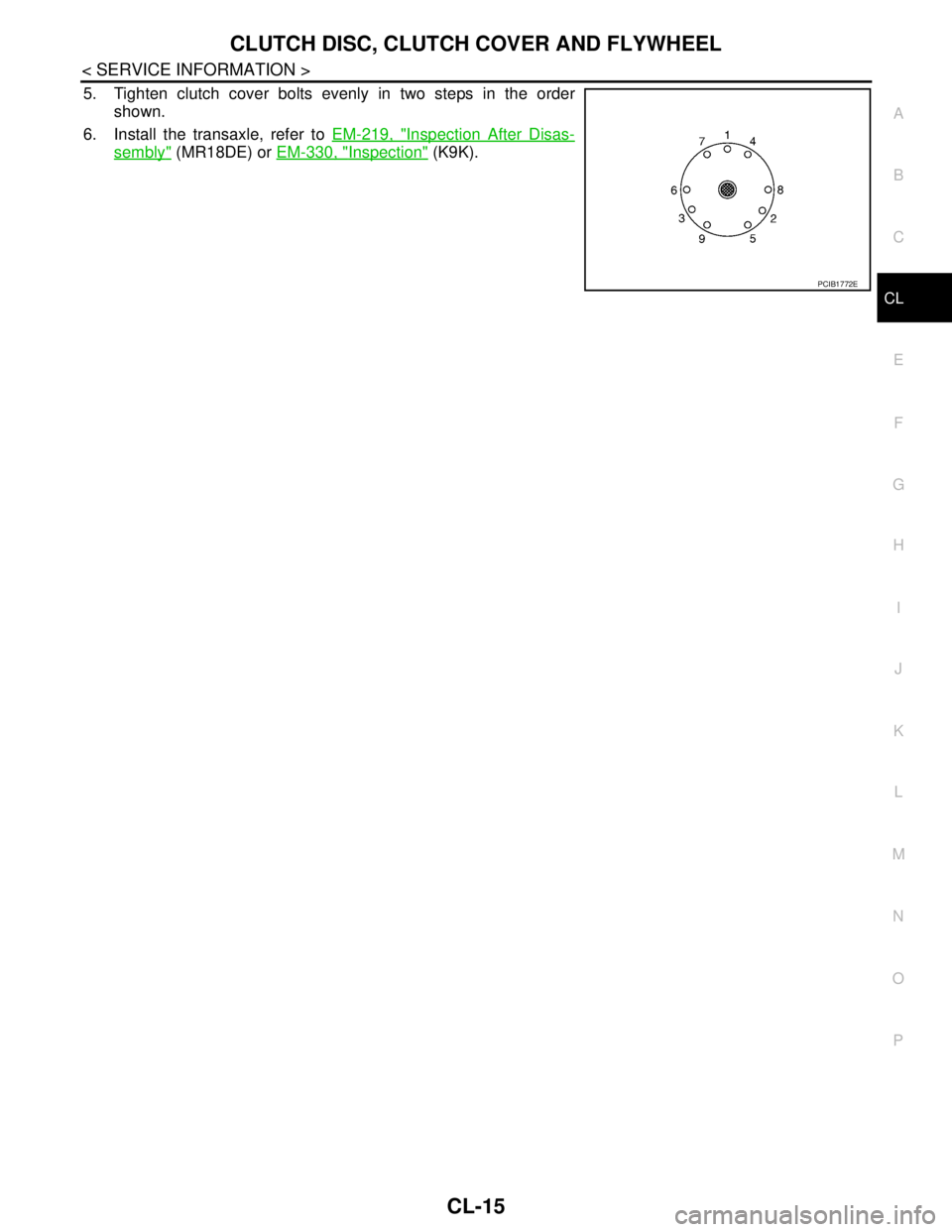

5. Tighten clutch cover bolts evenly in two steps in the order

shown.

6. Install the transaxle, refer to EM-219, "

Inspection After Disas-

sembly" (MR18DE) or EM-330, "Inspection" (K9K).

PCIB1772E