NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2241 of 3066

FSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

CautionEES0006Z

lWhen installing rubber bushings, final tightening must be carried out under unladen conditions with tires

on flat, level ground. Oil will shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

l“Unladen condition” means that fuel, coolant and lubricant are full and ready for drive. However, spare tire,

jack, and hand tools should be unloaded.

lAfter installing the removed suspension parts, always check wheel alignment and adjust if necessary.

lReplace the caulking nut with a new one. Install a new nut without wiping the oil off before tightening.

Precautions for Brake SystemEES000JA

lWhen installing rubber parts, final tightening must be carried out

under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake tubes.

lAfter installing removed suspension parts, check wheel align-

ment and adjust if necessary.

lAlways torque brake lines when installing.

SBR686C

Page 2242 of 3066

PREPARATION

FSU-3

C

D

F

G

H

I

J

K

L

MA

B

FSU

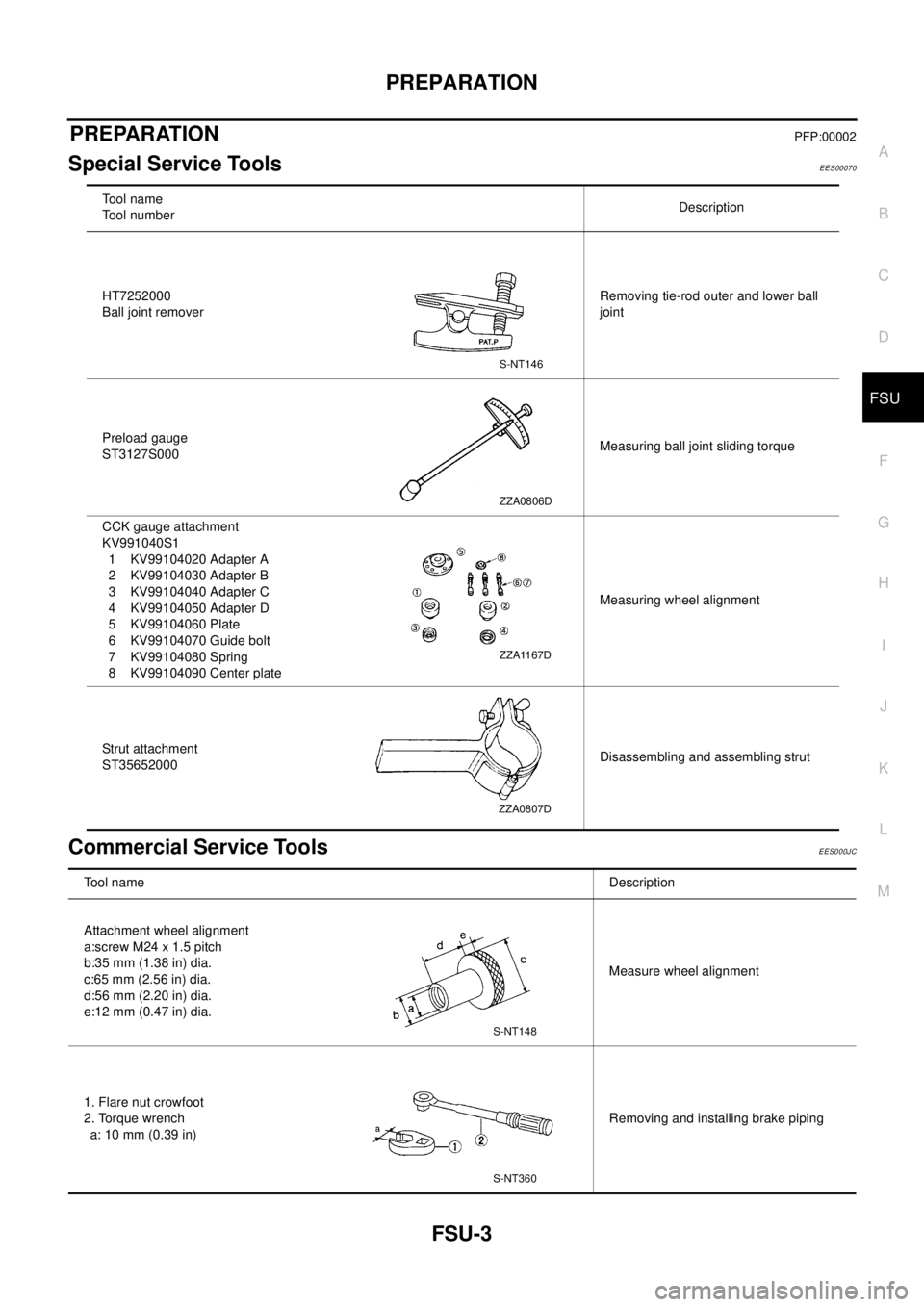

PREPARATIONPFP:00002

Special Service ToolsEES00070

Commercial Service ToolsEES000JC

To o l n a m e

Tool numberDescription

HT7252000

Ball joint removerRemoving tie-rod outer and lower ball

joint

Preload gauge

ST3127S000Measuring ball joint sliding torque

CCK gauge attachment

KV991040S1

1 KV99104020 Adapter A

2 KV99104030 Adapter B

3 KV99104040 Adapter C

4 KV99104050 Adapter D

5 KV99104060 Plate

6 KV99104070 Guide bolt

7 KV99104080 Spring

8 KV99104090 Center plateMeasuring wheel alignment

Strut attachment

ST35652000Disassembling and assembling strut

S-NT146

ZZA0806D

ZZA1167D

ZZA0807D

Tool nameDescription

Attachment wheel alignment

a:screw M24 x 1.5 pitch

b:35 mm (1.38 in) dia.

c:65 mm (2.56 in) dia.

d:56 mm (2.20 in) dia.

e:12 mm (0.47 in) dia.Measure wheel alignment

1. Flare nut crowfoot

2. Torque wrench

a: 10 mm (0.39 in)Removing and installing brake piping

S-NT148

S-NT360

Page 2243 of 3066

FSU-4

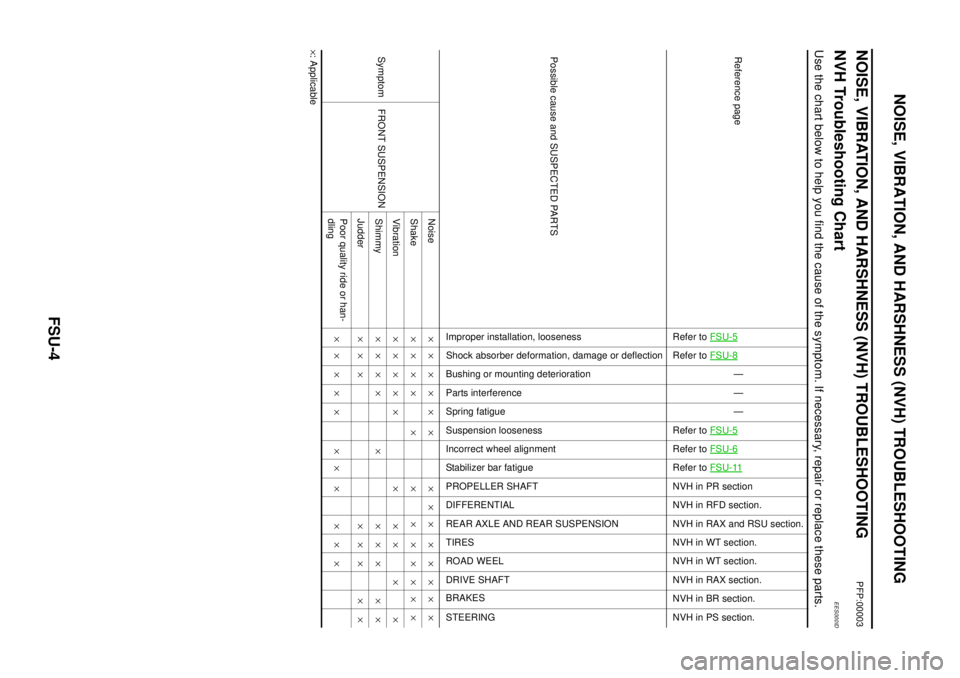

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

NVH Troubleshooting ChartEES000ID

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

Refer toFSU-5Refer toFSU-8

—

—

—

Refer toFSU-5

Refer toFSU-6Refer toFSU-11NVH in PR section

NVH in RFD section.

NVHinRAXandRSUsection.

NVH in WT section.

NVH in WT section.

NVH in RAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

PROPELLER SHAFT

DIFFERENTIAL

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom FRONT SUSPENSIONNoise´´´´´ ´ ´´´ ´´´´´

Shake´´´´ ´ ´ ´ ´´´´´

Vibration´´´´´ ´ ´´ ´ ´

Shimmy´´´´ ´ ´´´ ´´

Judder´´´ ´´´ ´´

Poor quality ride or han-

dling´´´´´ ´´ ´ ´´´

Page 2244 of 3066

FRONT SUSPENSION ASSEMBLY

FSU-5

C

D

F

G

H

I

J

K

L

MA

B

FSU

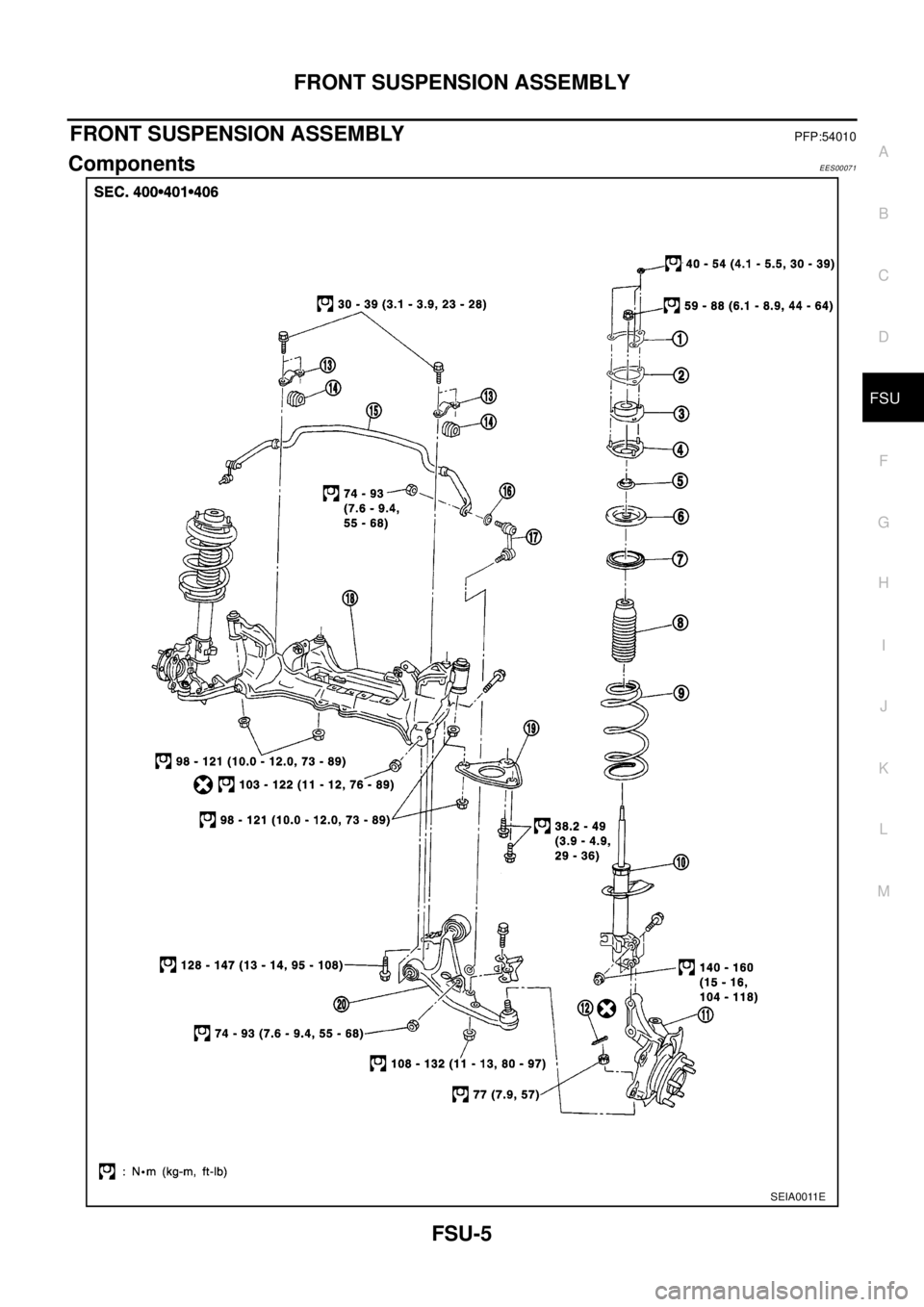

FRONT SUSPENSION ASSEMBLYPFP:54010

ComponentsEES00071

SEIA0011E

Page 2245 of 3066

FSU-6

FRONT SUSPENSION ASSEMBLY

On-Vehicle Inspection and Service

EES00072

LOOSENESS, BACKLASH AND DAMAGE OF MOUNTING PARTS AND CONNECTIONS

Lift vehicle and inspect the following:

lCheck mounting point of each component for looseness, backlash and damage.

lCheck lower ball joint end play.

1. Attach a dial gauge so that the contact rests on the brake caliper.

2. Set front wheels in a straight-ahead position. Do not depress brake pedal.

3. Measure axial endplay by placing an iron pry bar or something similar between transverse link and steer-

ing knuckle.

CAUTION:

Be careful not to damage ball joint boot.

4. If axial endplay is outside the standard, remove transverse link and check lower ball joint.

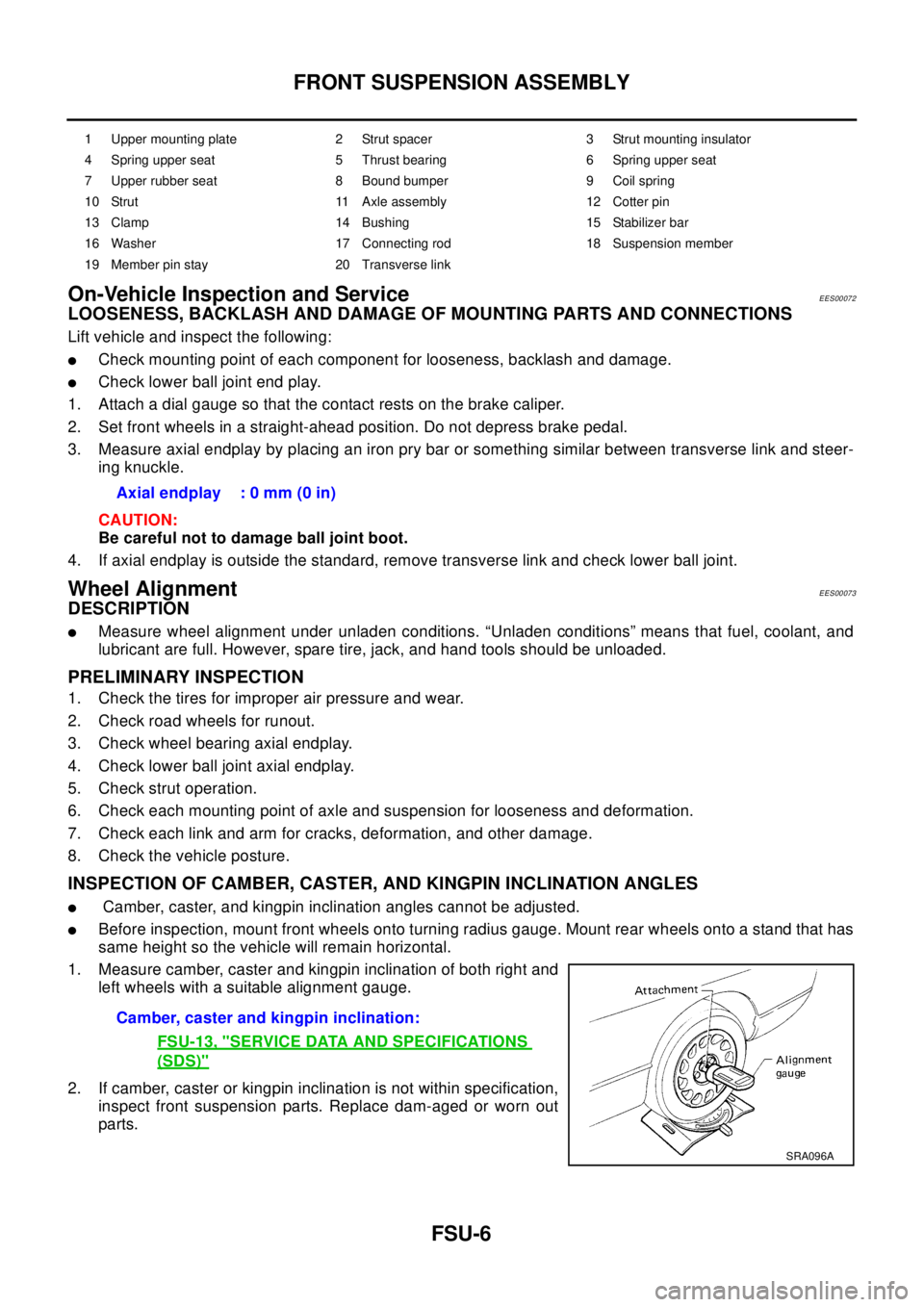

Wheel AlignmentEES00073

DESCRIPTION

lMeasure wheel alignment under unladen conditions. “Unladen conditions” means that fuel, coolant, and

lubricant are full. However, spare tire, jack, and hand tools should be unloaded.

PRELIMINARY INSPECTION

1. Check the tires for improper air pressure and wear.

2. Check road wheels for runout.

3. Check wheel bearing axial endplay.

4. Check lower ball joint axial endplay.

5. Check strut operation.

6. Check each mounting point of axle and suspension for looseness and deformation.

7. Check each link and arm for cracks, deformation, and other damage.

8. Check the vehicle posture.

INSPECTION OF CAMBER, CASTER, AND KINGPIN INCLINATION ANGLES

lCamber, caster, and kingpin inclination angles cannot be adjusted.

lBefore inspection, mount front wheels onto turning radius gauge. Mount rear wheels onto a stand that has

same height so the vehicle will remain horizontal.

1. Measure camber, caster and kingpin inclination of both right and

left wheels with a suitable alignment gauge.

2. If camber, caster or kingpin inclination is not within specification,

inspect front suspension parts. Replace dam-aged or worn out

parts.

1 Upper mounting plate 2 Strut spacer 3 Strut mounting insulator

4 Spring upper seat 5 Thrust bearing 6 Spring upper seat

7 Upper rubber seat 8 Bound bumper 9 Coil spring

10 Strut 11 Axle assembly 12 Cotter pin

13 Clamp 14 Bushing 15 Stabilizer bar

16 Washer 17 Connecting rod 18 Suspension member

19 Member pin stay 20 Transverse link

Axial endplay : 0 mm (0 in)

Camber, caster and kingpin inclination:

FSU-13, "

SERVICE DATA AND SPECIFICATIONS

(SDS)"

SRA096A

Page 2246 of 3066

FRONT SUSPENSION ASSEMBLY

FSU-7

C

D

F

G

H

I

J

K

L

MA

B

FSU

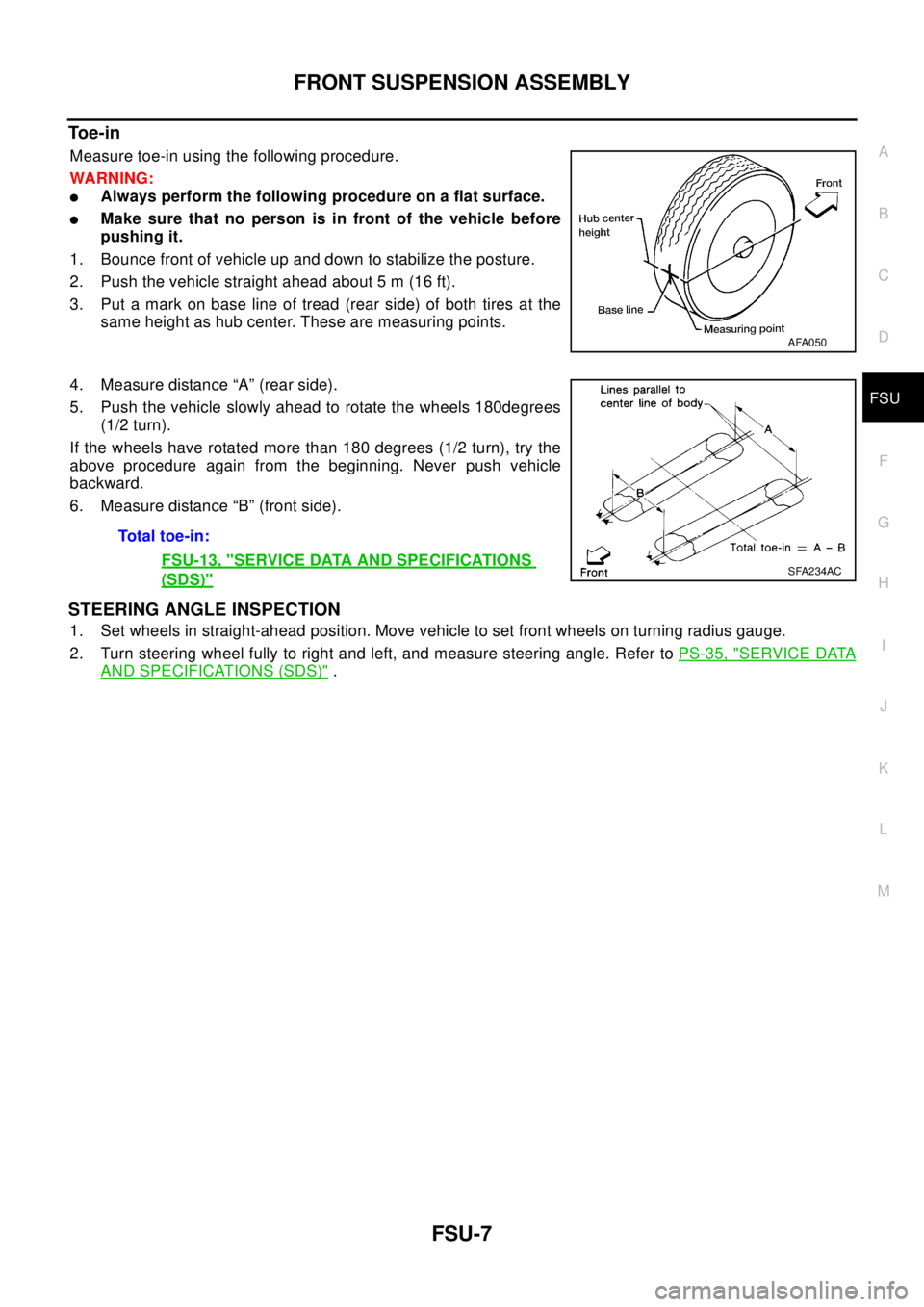

To e - i n

Measure toe-in using the following procedure.

WA RN ING:

lAlways perform the following procedure on a flat surface.

lMake sure that no person is in front of the vehicle before

pushing it.

1. Bounce front of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of tread (rear side) of both tires at the

same height as hub center. These are measuring points.

4. Measure distance “A” (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180degrees

(1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn), try the

above procedure again from the beginning. Never push vehicle

backward.

6. Measure distance “B” (front side).

STEERING ANGLE INSPECTION

1. Set wheels in straight-ahead position. Move vehicle to set front wheels on turning radius gauge.

2. Turn steering wheel fully to right and left, and measure steering angle. Refer toPS-35, "

SERVICE DATA

AND SPECIFICATIONS (SDS)".

AFA050

Total toe-in:

FSU-13, "

SERVICE DATA AND SPECIFICATIONS

(SDS)"SFA234AC

Page 2247 of 3066

FSU-8

COIL SPRING AND SHOCK ABSORBER

COIL SPRING AND SHOCK ABSORBER

PFP:54302

Removal and InstallationEES00074

REMOVAL

1. Remove tires. Remove brake caliper and hung it aside.

CAUTION:

Avoid depressing brake pedal with brake caliper removed.

2. Remove electrical wires of ABS wheel speed sensor from strut.

3. Remove brake hose lock plate.

4. Remove mounting bolts and nuts securing steering knuckle to strut.

5. Remove mounting nuts on top of strut and remove upper mounting plate and strut from vehicle.

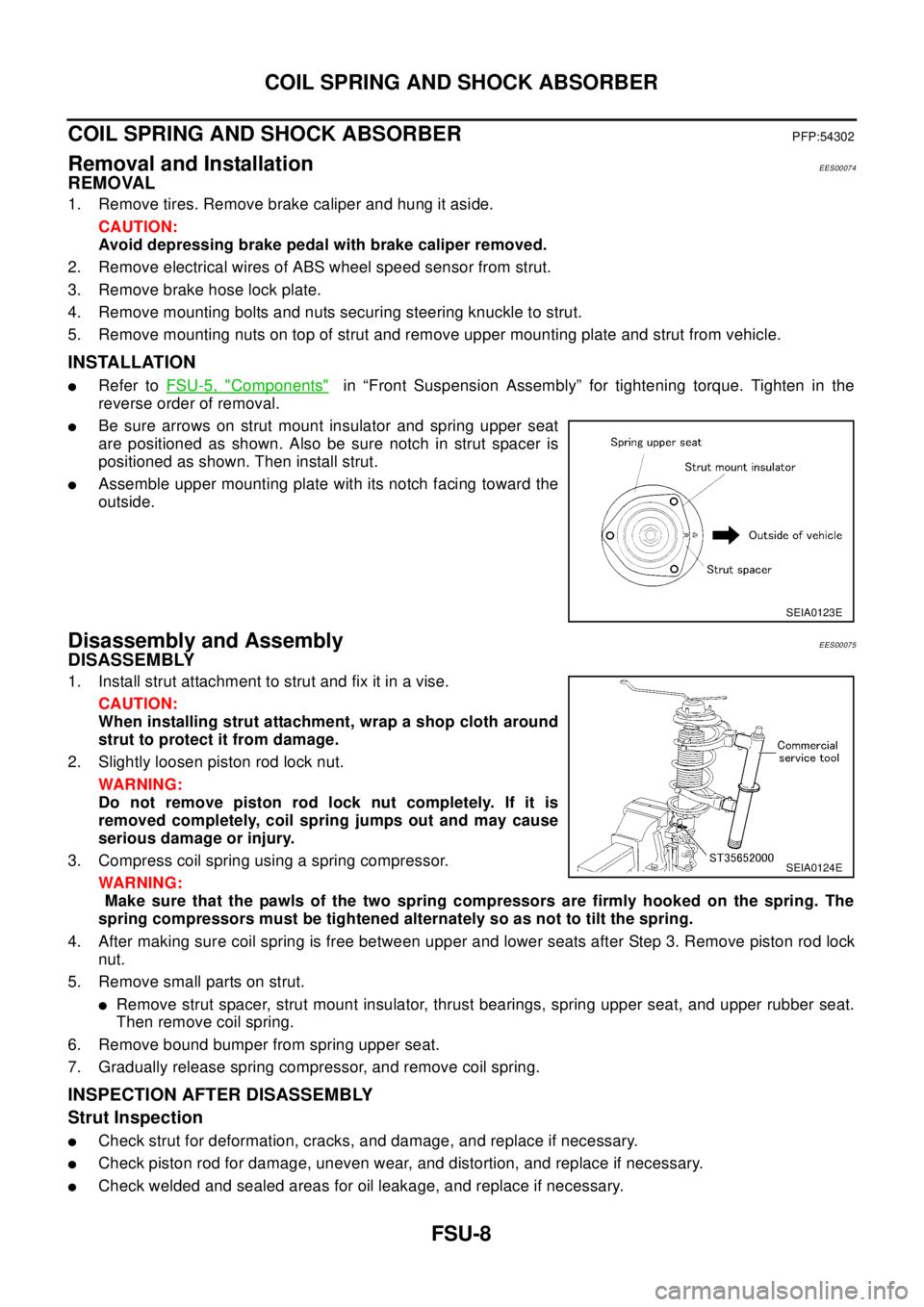

INSTALLATION

lRefer toFSU-5, "Components"in “Front Suspension Assembly” for tightening torque. Tighten in the

reverse order of removal.

lBe sure arrows on strut mount insulator and spring upper seat

are positioned as shown. Also be sure notch in strut spacer is

positioned as shown. Then install strut.

lAssemble upper mounting plate with its notch facing toward the

outside.

Disassembly and AssemblyEES00075

DISASSEMBLY

1. Install strut attachment to strut and fix it in a vise.

CAUTION:

When installing strut attachment, wrap a shop cloth around

strut to protect it from damage.

2. Slightly loosen piston rod lock nut.

WAR NIN G:

Do not remove piston rod lock nut completely. If it is

removed completely, coil spring jumps out and may cause

serious damage or injury.

3. Compress coil spring using a spring compressor.

WAR NIN G:

Make sure that the pawls of the two spring compressors are firmly hooked on the spring. The

spring compressors must be tightened alternately so as not to tilt the spring.

4. After making sure coil spring is free between upper and lower seats after Step 3. Remove piston rod lock

nut.

5. Remove small parts on strut.

lRemove strut spacer, strut mount insulator, thrust bearings, spring upper seat, and upper rubber seat.

Then remove coil spring.

6. Remove bound bumper from spring upper seat.

7. Gradually release spring compressor, and remove coil spring.

INSPECTION AFTER DISASSEMBLY

Strut Inspection

lCheck strut for deformation, cracks, and damage, and replace if necessary.

lCheck piston rod for damage, uneven wear, and distortion, and replace if necessary.

lCheck welded and sealed areas for oil leakage, and replace if necessary.

SEIA0123E

SEIA0124E

Page 2248 of 3066

COIL SPRING AND SHOCK ABSORBER

FSU-9

C

D

F

G

H

I

J

K

L

MA

B

FSU

Insulator and Rubber Parts Inspection

Check strut mount insulator for cracks and rubber parts for wear. Replace them if necessary.

Coil Spring Inspection

Check for cracks, wear, and damage, and replace if necessary.

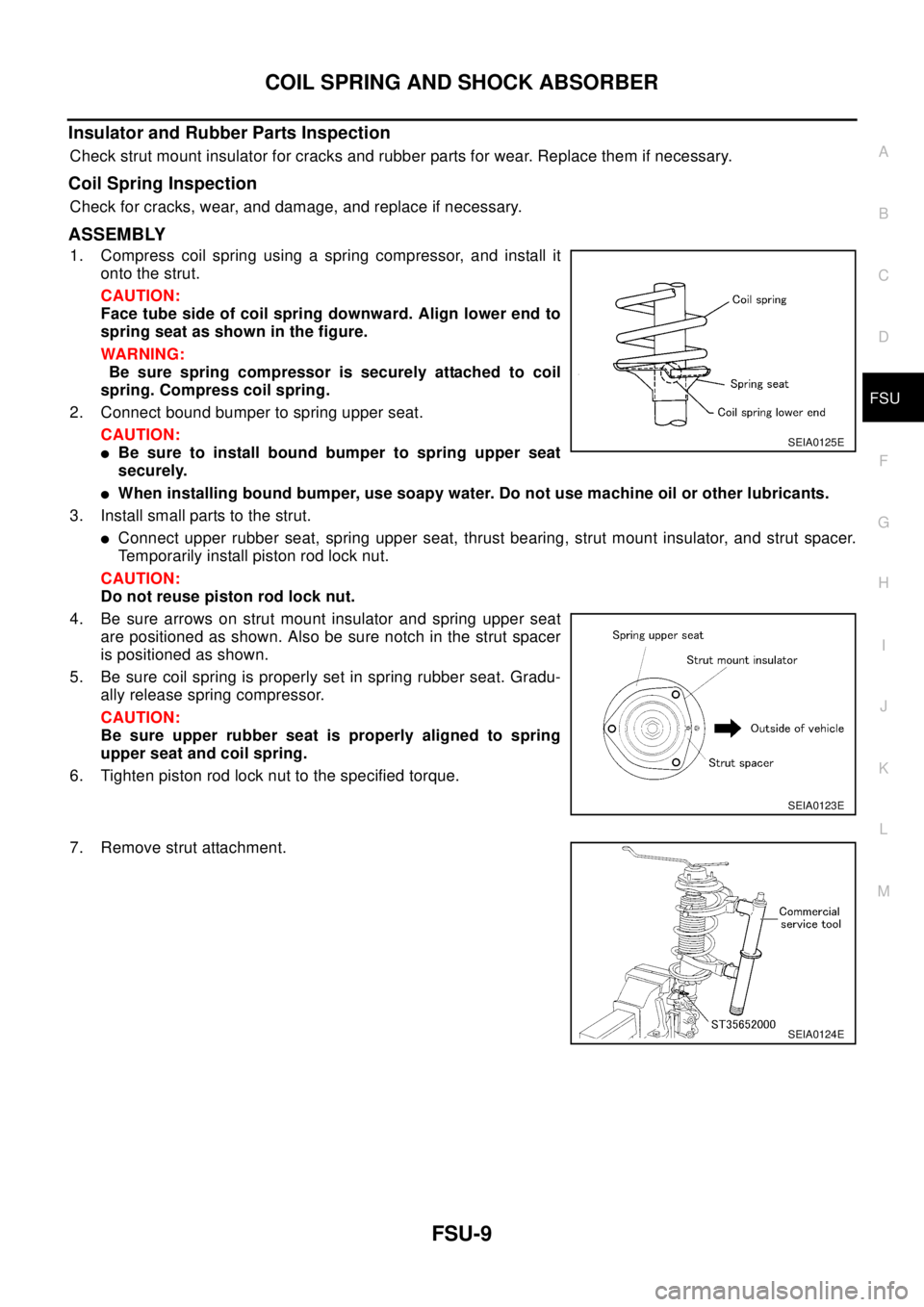

ASSEMBLY

1. Compress coil spring using a spring compressor, and install it

onto the strut.

CAUTION:

Face tube side of coil spring downward. Align lower end to

spring seat as shown in the figure.

WAR NIN G:

Be sure spring compressor is securely attached to coil

spring. Compress coil spring.

2. Connect bound bumper to spring upper seat.

CAUTION:

lBe sure to install bound bumper to spring upper seat

securely.

lWhen installing bound bumper, use soapy water. Do not use machine oil or other lubricants.

3. Install small parts to the strut.

lConnect upper rubber seat, spring upper seat, thrust bearing, strut mount insulator, and strut spacer.

Temporarily install piston rod lock nut.

CAUTION:

Do not reuse piston rod lock nut.

4. Be sure arrows on strut mount insulator and spring upper seat

are positioned as shown. Also be sure notch in the strut spacer

is positioned as shown.

5. Be sure coil spring is properly set in spring rubber seat. Gradu-

ally release spring compressor.

CAUTION:

Be sure upper rubber seat is properly aligned to spring

upper seat and coil spring.

6. Tighten piston rod lock nut to the specified torque.

7. Remove strut attachment.

SEIA0125E

SEIA0123E

SEIA0124E

Page 2249 of 3066

FSU-10

TRANSVERSE LINK

TRANSVERSE LINK

PFP:54500

Removal and InstallationEES00076

REMOVAL

1. Remove steering knuckle from transverse link. Refer toFAX-7, "REMOVAL".

2. Remove mounting nuts and washers on lower portion of stabilizer connecting rod.

3. Slightly loosen transverse link mounting bolts.

4. Remove compression rod bracket mounting bolts.

5. Remove transverse link mounting bolts and nuts, and remove transverse link from suspension member.

INSPECTION AFTER REMOVAL

Visual Inspection

Check transverse link and bushing for deformation, cracks, and other damage. Replace the entire transverse

link assembly if cracks, deformation or any other damage is found.

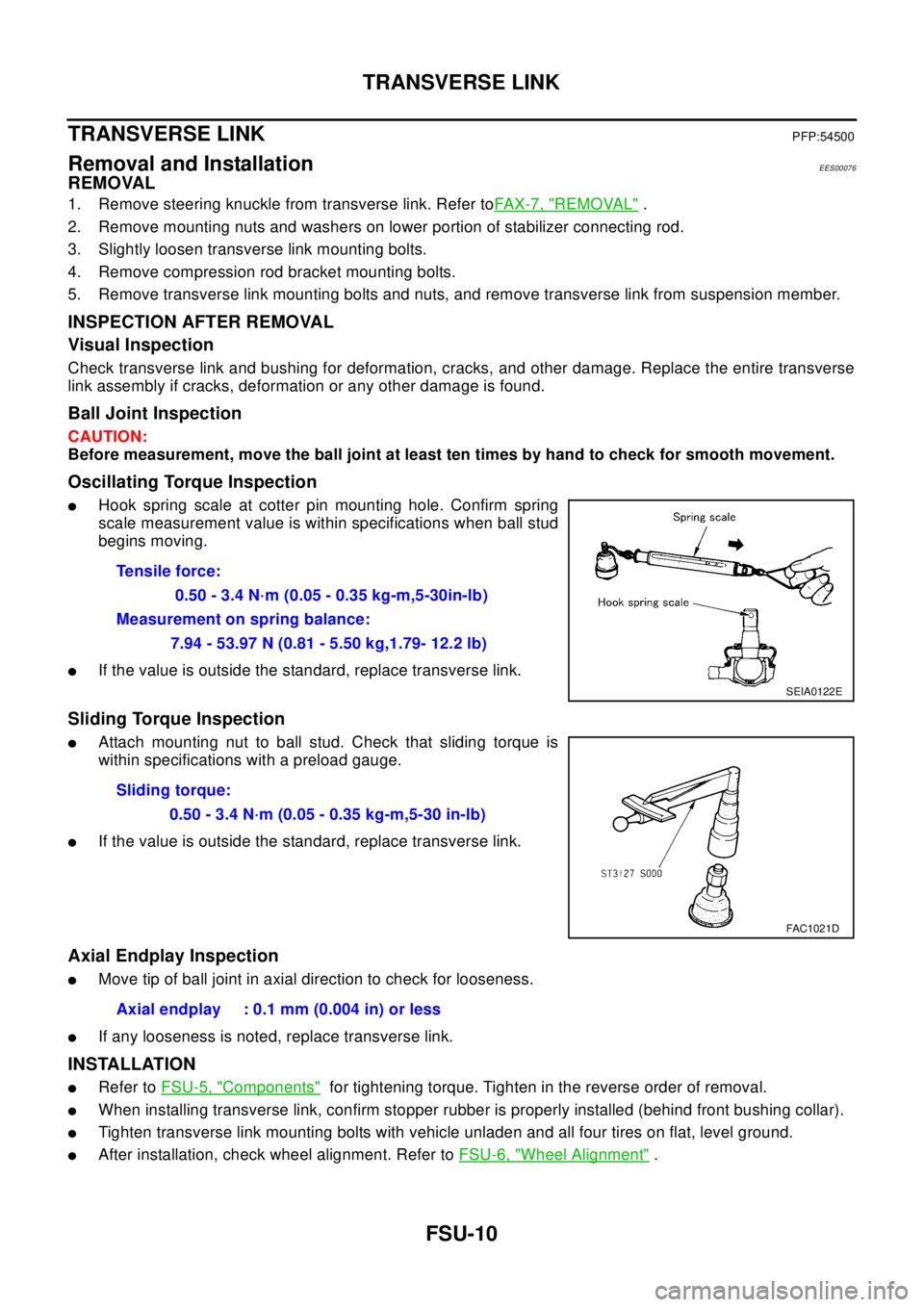

Ball Joint Inspection

CAUTION:

Before measurement, move the ball joint at least ten times by hand to check for smooth movement.

Oscillating Torque Inspection

lHook spring scale at cotter pin mounting hole. Confirm spring

scale measurement value is within specifications when ball stud

begins moving.

lIf the value is outside the standard, replace transverse link.

Sliding Torque Inspection

lAttach mounting nut to ball stud. Check that sliding torque is

within specifications with a preload gauge.

lIf the value is outside the standard, replace transverse link.

Axial Endplay Inspection

lMove tip of ball joint in axial direction to check for looseness.

lIf any looseness is noted, replace transverse link.

INSTALLATION

lRefer toFSU-5, "Components"for tightening torque. Tighten in the reverse order of removal.

lWhen installing transverse link, confirm stopper rubber is properly installed (behind front bushing collar).

lTighten transverse link mounting bolts with vehicle unladen and all four tires on flat, level ground.

lAfter installation, check wheel alignment. Refer toFSU-6, "Wheel Alignment". Tensile force:

0.50 - 3.4 N·m (0.05 - 0.35 kg-m,5-30in-lb)

Measurement on spring balance:

7.94 - 53.97 N (0.81 - 5.50 kg,1.79- 12.2 lb)

SEIA0122E

Sliding torque:

0.50 - 3.4 N·m (0.05 - 0.35 kg-m,5-30 in-lb)

FAC1021D

Axial endplay : 0.1 mm (0.004 in) or less

Page 2250 of 3066

STABILIZER BAR

FSU-11

C

D

F

G

H

I

J

K

L

MA

B

FSU

STABILIZER BARPFP:54611

Removal and InstallationEES000HH

REMOVAL

1. Remove mounting nuts on upper portion of stabilizer connecting rod.

2. Remove stabilizer clamp mounting bolts.

3. Remove stabilizer from the vehicle.

INSPECTION AFTER REMOVAL

Check stabilizer, connecting rod, bushing and clamp for deformation, cracks and damage, and replace if nec-

essary.

INSTALLATION

lRefer toFSU-5, "Components"in the reverse order of removal.

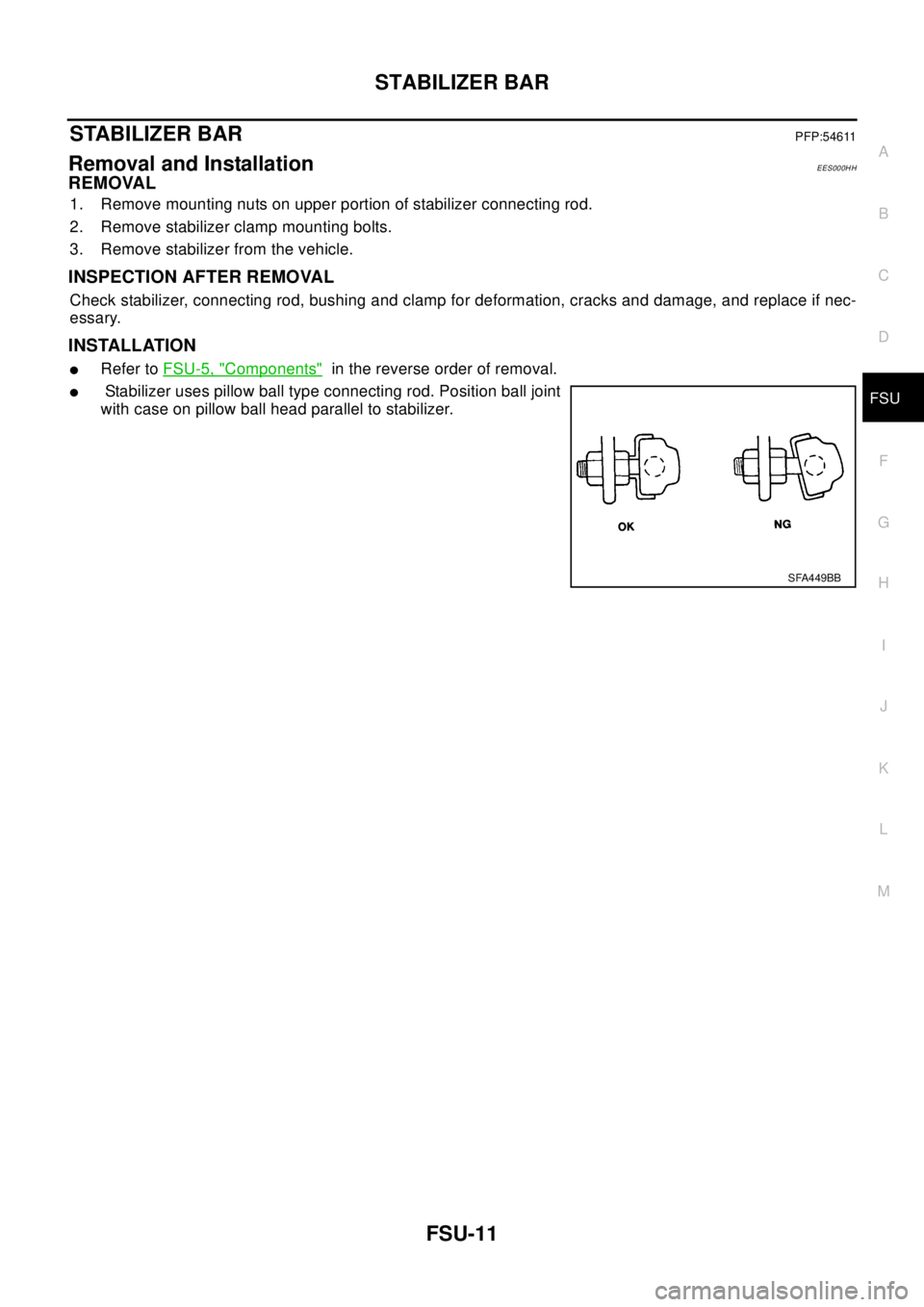

lStabilizer uses pillow ball type connecting rod. Position ball joint

with case on pillow ball head parallel to stabilizer.

SFA449BB