DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1081 of 1200

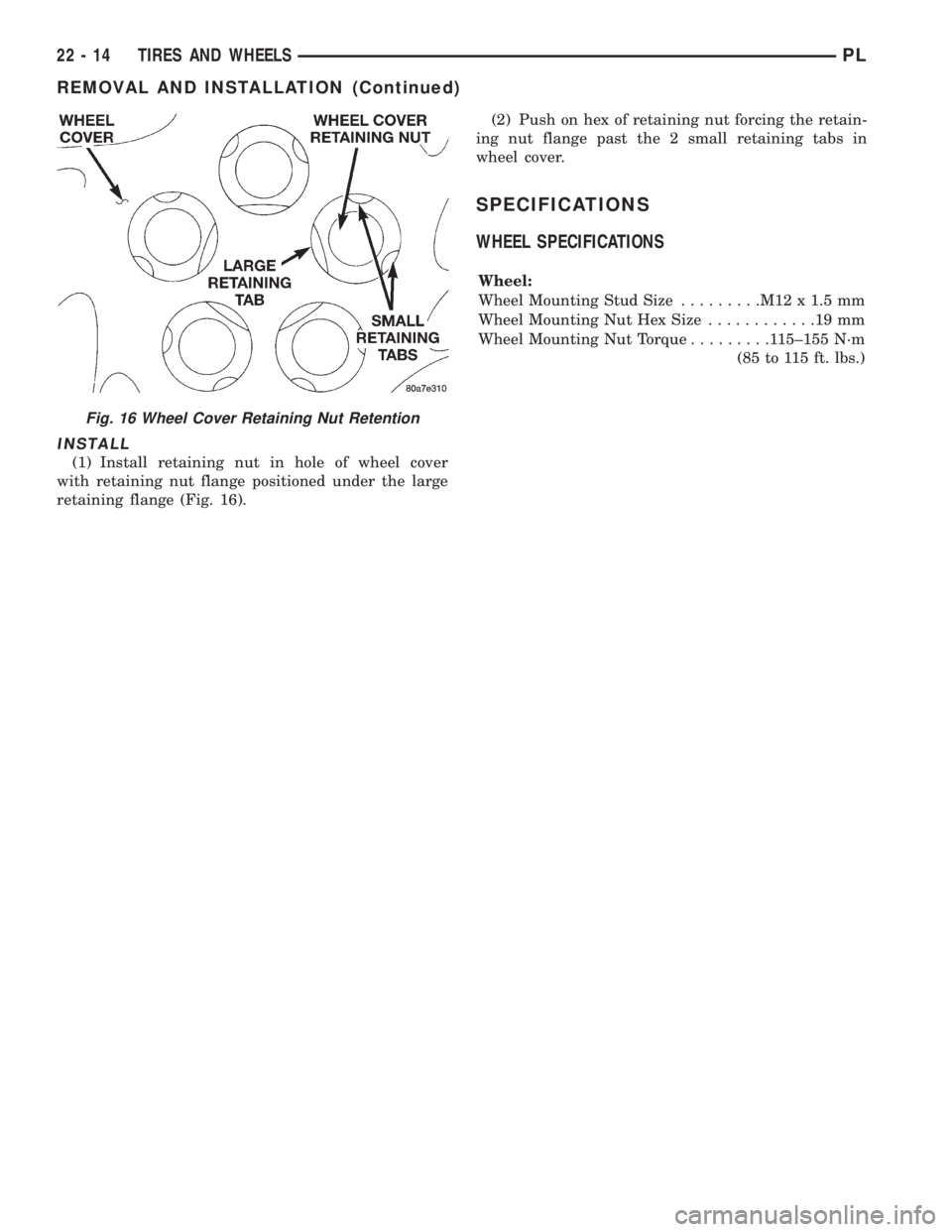

INSTALL

(1) Install retaining nut in hole of wheel cover

with retaining nut flange positioned under the large

retaining flange (Fig. 16).(2) Push on hex of retaining nut forcing the retain-

ing nut flange past the 2 small retaining tabs in

wheel cover.

SPECIFICATIONS

WHEEL SPECIFICATIONS

Wheel:

Wheel Mounting Stud Size.........M12 x 1.5 mm

Wheel Mounting Nut Hex Size............19mm

Wheel Mounting Nut Torque.........115±155 N´m

(85 to 115 ft. lbs.)

Fig. 16 Wheel Cover Retaining Nut Retention

22 - 14 TIRES AND WHEELSPL

REMOVAL AND INSTALLATION (Continued)

Page 1082 of 1200

BODY

CONTENTS

page page

BODY COMPONENTS...................... 2

GENERAL SERVICE INFORMATION........... 1

PAINT................................. 41STATIONARY GLASS...................... 43

SUNROOF.............................. 47

GENERAL SERVICE INFORMATION

INDEX

page

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS...... 1

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use

when welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body. Most of these fasteners can be

reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

PLBODY 23 - 1

Page 1083 of 1200

BODY COMPONENTS

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 3

WIND NOISE............................ 4

SERVICE PROCEDURES

HEAT STAKING.......................... 4

REMOVAL AND INSTALLATION

WINDOW REGULATORÐ4 DOOR........... 36

A-PILLAR TRIM.......................... 4

B-PILLAR APPLIQUEÐ2 DOOR.............. 5

B-PILLAR APPLIQUEÐ4 DOOR.............. 5

B-PILLAR TRIMÐ4 DOOR.................. 6

B-PILLAR WEATHERSTRIP CHANNEL......... 6

BODY VENT............................. 6

CARPET............................... 7

CHILD RESTRAINT SEAT BACK............. 8

CHILD SEAT MODULE..................... 8

COWL COVER........................... 7

DOOR HINGE........................... 9

DOOR LOCK CYLINDER.................. 10

DOOR OPENING TRIM WELT.............. 10

DOOR SILL TRIM........................ 10

DOOR................................. 9

FLOOR CONSOLE LATCH................. 11

FLOOR CONSOLE....................... 11

FRONT DOOR CHECK STOP............... 11

FRONT DOOR GLASSÐ2 DOOR............ 12

FRONT DOOR GLASSÐ4 DOOR............ 13

FRONT DOOR INNER BELT WEATHERSTRIP . . 13

FRONT DOOR LATCH STRIKER............ 14

FRONT DOOR LATCH.................... 13

FRONT DOOR OUTER BELT WEATHERSTRIP . 14

FRONT DOOR OUTSIDE HANDLE........... 14

FRONT DOOR TRIM PANEL................ 14

FRONT DOOR WATER SHIELD............. 16

FRONT DOOR WEATHERSTRIP............ 16

FRONT OUTBOARD SEAT BELT............ 17

FRONT SEAT BELT BUCKLE............... 18

FRONT SEAT BELT RETRACTOR........... 18

FRONT SEAT........................... 17

FRONT SHOULDER BELT ADJUSTER........ 18

FRONT VERTICAL GUIDE BAR............. 18

GRILLE............................... 19

HEADLINING........................... 19

HOOD HINGE.......................... 20

HOOD LATCH.......................... 21

HOOD RELEASE CABLE.................. 21

HOOD................................ 20

LOCK BUTTON BELL-CRANK.............. 21

LOWER QUARTER TRIMÐ4 DOOR.......... 22PARCEL SHELF TRIM.................... 22

QUARTER TRIM PANELÐ2 DOOR........... 22

REAR DOOR GLASS..................... 23

REAR DOOR INNER BELT WEATHERSTRIP . . . 23

REAR DOOR INTERLOCK LATCH STRIKER . . . 24

REAR DOOR LATCH STRIKER............. 24

REAR DOOR LATCH..................... 24

REAR DOOR LOCK BELL CRANK........... 24

REAR DOOR OUTER BELT WEATHERSTRIP . . 25

REAR DOOR TRIM....................... 25

REAR DOOR WINDOW REGULATOR........ 25

REAR SEAT BACK....................... 26

REAR SEAT BELT BUCKLE................ 26

REAR SEAT BELT RETRACTOR............ 26

REAR SEAT CUSHION.................... 26

REAR SPOILER......................... 27

REAR VERTICAL GUIDE BAR.............. 27

ROOF APERTURE (RAP) MOLDING.......... 28

ROOF RACK CROSS RAILS............... 28

ROOF RACK........................... 28

ROOF RAIL WEATHER-STRIP FOUR DOOR . . . 29

ROOF RAIL WEATHER-STRIP ± TWO DOOR . . . 29

SIDE COWL TRIM....................... 30

SIDE VIEW MIRROR STANCHION........... 31

SIDE VIEW MIRROR TRIM COVER.......... 31

SIDE VIEW MIRROR..................... 30

SUN VISOR SUPPORT................... 31

SUN VISOR............................ 31

TRUNK CARPET........................ 31

TRUNK LATCH STRIKER.................. 32

TRUNK LATCH.......................... 32

TRUNK LID LIFT SPRINGS................ 33

TRUNK LID............................ 32

TRUNK LOCK CYLINDER................. 33

TRUNK TRIM PANEL..................... 34

TRUNK WEATHERSTRIP.................. 34

UPPER QUARTER TRIMÐ4 DOOR.......... 34

WINDOW INNERBELT STABILIZER.......... 34

WINDOW REGULATORÐ2 DOOR........... 35

ADJUSTMENTS

FRONT DOOR GLASS ADJUSTMENT........ 37

FRONT DOOR LATCH ADJUSTMENT........ 38

REAR DOOR GLASS ADJUSTMENT......... 38

REAR DOOR LATCH ADJUSTMENT.......... 39

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS....... 39

SPECIAL TOOLS

BODY................................. 40

23 - 2 BODYPL

Page 1084 of 1200

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK

TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

PLBODY 23 - 3

Page 1085 of 1200

WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

crosswinds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

SERVICE PROCEDURES

HEAT STAKING

(1) Remove trim panel.

(2) Bend or move the trim panel components at

the heat staked joints. Observe the heat staked loca-

tions and/or component seams for looseness.(3) Heat stake the components.

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightly

together and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-

ing the glue. Once the new material is in place, it

may be necessary to use a soldering gun to melt

the newly applied material. Do not over heat the

affected area, damage to the exterior of the trim

panel may occur.

(4) Allow the repaired area to cool and verify the

repair.

(5) Install trim panel.

REMOVAL AND INSTALLATION

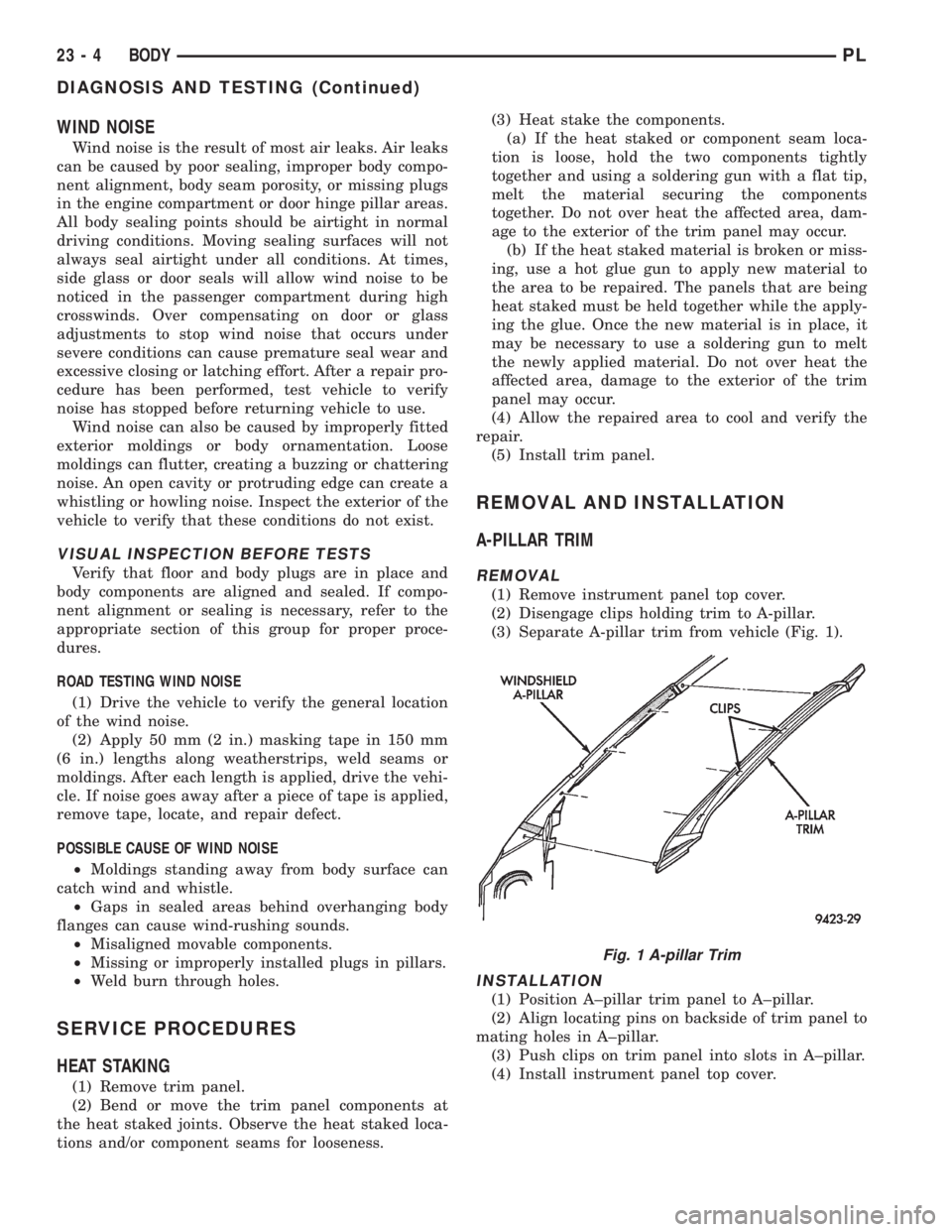

A-PILLAR TRIM

REMOVAL

(1) Remove instrument panel top cover.

(2) Disengage clips holding trim to A-pillar.

(3) Separate A-pillar trim from vehicle (Fig. 1).

INSTALLATION

(1) Position A±pillar trim panel to A±pillar.

(2) Align locating pins on backside of trim panel to

mating holes in A±pillar.

(3) Push clips on trim panel into slots in A±pillar.

(4) Install instrument panel top cover.

Fig. 1 A-pillar Trim

23 - 4 BODYPL

DIAGNOSIS AND TESTING (Continued)

Page 1086 of 1200

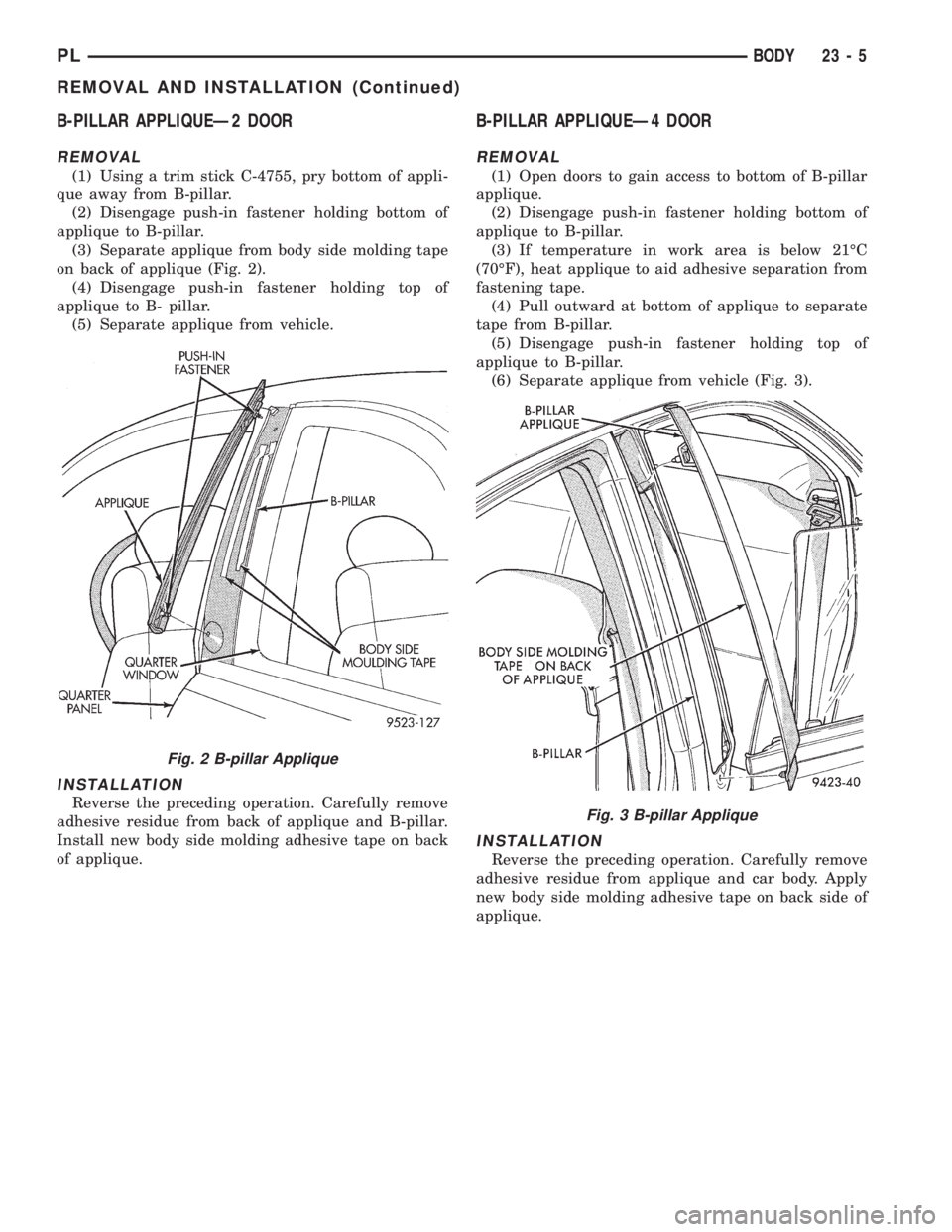

B-PILLAR APPLIQUEÐ2 DOOR

REMOVAL

(1) Using a trim stick C-4755, pry bottom of appli-

que away from B-pillar.

(2) Disengage push-in fastener holding bottom of

applique to B-pillar.

(3) Separate applique from body side molding tape

on back of applique (Fig. 2).

(4) Disengage push-in fastener holding top of

applique to B- pillar.

(5) Separate applique from vehicle.

INSTALLATION

Reverse the preceding operation. Carefully remove

adhesive residue from back of applique and B-pillar.

Install new body side molding adhesive tape on back

of applique.

B-PILLAR APPLIQUEÐ4 DOOR

REMOVAL

(1) Open doors to gain access to bottom of B-pillar

applique.

(2) Disengage push-in fastener holding bottom of

applique to B-pillar.

(3) If temperature in work area is below 21ÉC

(70ÉF), heat applique to aid adhesive separation from

fastening tape.

(4) Pull outward at bottom of applique to separate

tape from B-pillar.

(5) Disengage push-in fastener holding top of

applique to B-pillar.

(6) Separate applique from vehicle (Fig. 3).

INSTALLATION

Reverse the preceding operation. Carefully remove

adhesive residue from applique and car body. Apply

new body side molding adhesive tape on back side of

applique.

Fig. 2 B-pillar Applique

Fig. 3 B-pillar Applique

PLBODY 23 - 5

REMOVAL AND INSTALLATION (Continued)

Page 1087 of 1200

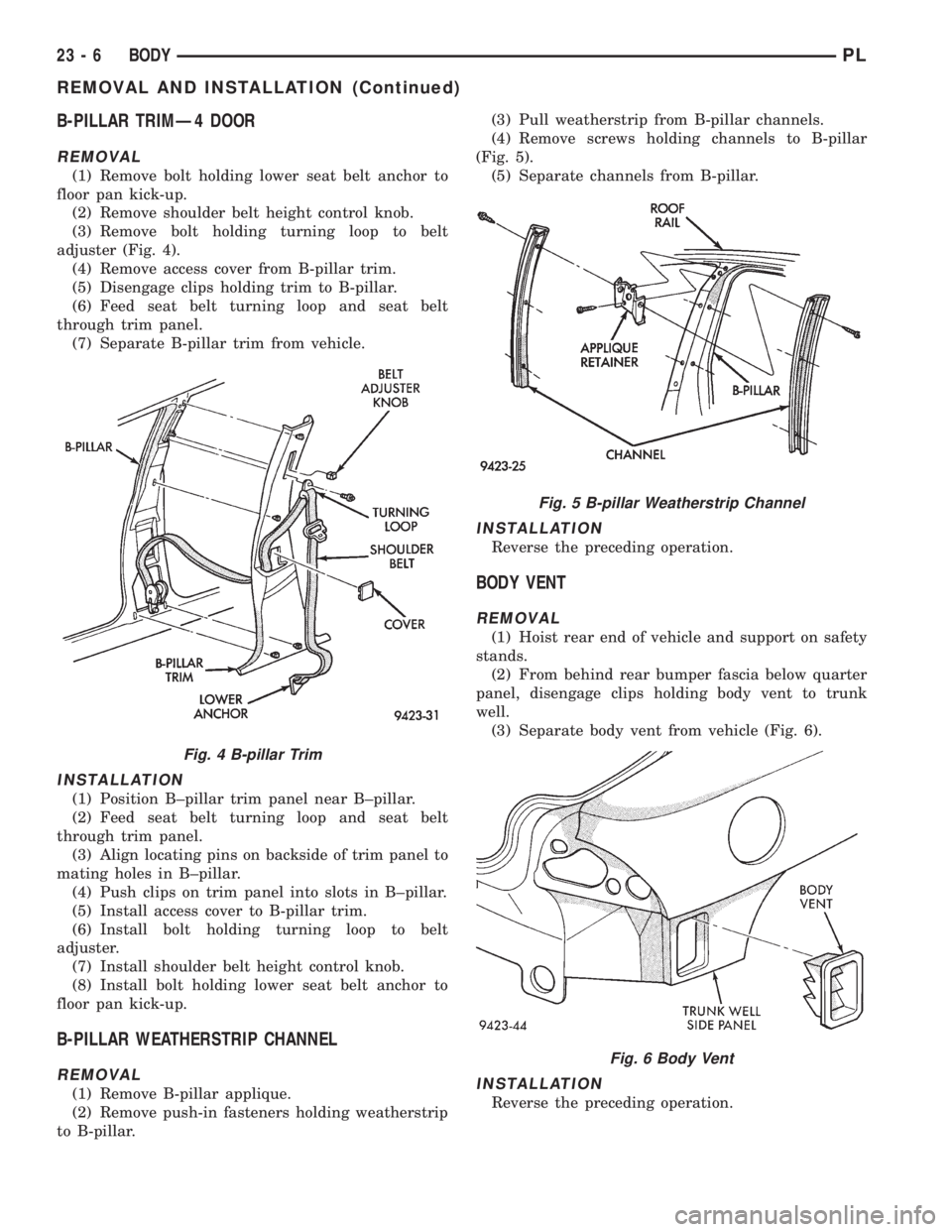

B-PILLAR TRIMÐ4 DOOR

REMOVAL

(1) Remove bolt holding lower seat belt anchor to

floor pan kick-up.

(2) Remove shoulder belt height control knob.

(3) Remove bolt holding turning loop to belt

adjuster (Fig. 4).

(4) Remove access cover from B-pillar trim.

(5) Disengage clips holding trim to B-pillar.

(6) Feed seat belt turning loop and seat belt

through trim panel.

(7) Separate B-pillar trim from vehicle.

INSTALLATION

(1) Position B±pillar trim panel near B±pillar.

(2) Feed seat belt turning loop and seat belt

through trim panel.

(3) Align locating pins on backside of trim panel to

mating holes in B±pillar.

(4) Push clips on trim panel into slots in B±pillar.

(5) Install access cover to B-pillar trim.

(6) Install bolt holding turning loop to belt

adjuster.

(7) Install shoulder belt height control knob.

(8) Install bolt holding lower seat belt anchor to

floor pan kick-up.

B-PILLAR WEATHERSTRIP CHANNEL

REMOVAL

(1) Remove B-pillar applique.

(2) Remove push-in fasteners holding weatherstrip

to B-pillar.(3) Pull weatherstrip from B-pillar channels.

(4) Remove screws holding channels to B-pillar

(Fig. 5).

(5) Separate channels from B-pillar.

INSTALLATION

Reverse the preceding operation.

BODY VENT

REMOVAL

(1) Hoist rear end of vehicle and support on safety

stands.

(2) From behind rear bumper fascia below quarter

panel, disengage clips holding body vent to trunk

well.

(3) Separate body vent from vehicle (Fig. 6).

INSTALLATION

Reverse the preceding operation.

Fig. 4 B-pillar Trim

Fig. 5 B-pillar Weatherstrip Channel

Fig. 6 Body Vent

23 - 6 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1088 of 1200

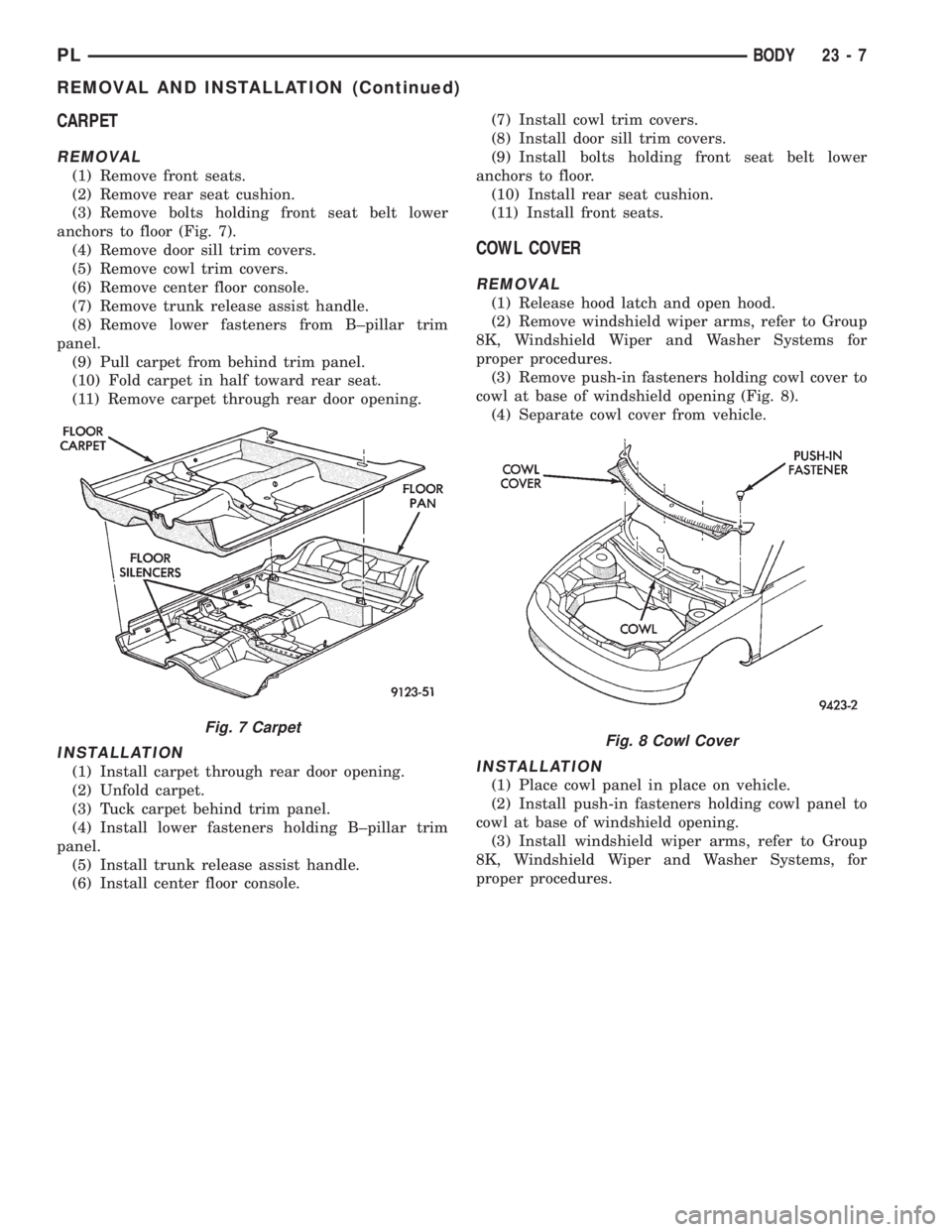

CARPET

REMOVAL

(1) Remove front seats.

(2) Remove rear seat cushion.

(3) Remove bolts holding front seat belt lower

anchors to floor (Fig. 7).

(4) Remove door sill trim covers.

(5) Remove cowl trim covers.

(6) Remove center floor console.

(7) Remove trunk release assist handle.

(8) Remove lower fasteners from B±pillar trim

panel.

(9) Pull carpet from behind trim panel.

(10) Fold carpet in half toward rear seat.

(11) Remove carpet through rear door opening.

INSTALLATION

(1) Install carpet through rear door opening.

(2) Unfold carpet.

(3) Tuck carpet behind trim panel.

(4) Install lower fasteners holding B±pillar trim

panel.

(5) Install trunk release assist handle.

(6) Install center floor console.(7) Install cowl trim covers.

(8) Install door sill trim covers.

(9) Install bolts holding front seat belt lower

anchors to floor.

(10) Install rear seat cushion.

(11) Install front seats.

COWL COVER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems for

proper procedures.

(3) Remove push-in fasteners holding cowl cover to

cowl at base of windshield opening (Fig. 8).

(4) Separate cowl cover from vehicle.

INSTALLATION

(1) Place cowl panel in place on vehicle.

(2) Install push-in fasteners holding cowl panel to

cowl at base of windshield opening.

(3) Install windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems, for

proper procedures.

Fig. 7 CarpetFig. 8 Cowl Cover

PLBODY 23 - 7

REMOVAL AND INSTALLATION (Continued)

Page 1089 of 1200

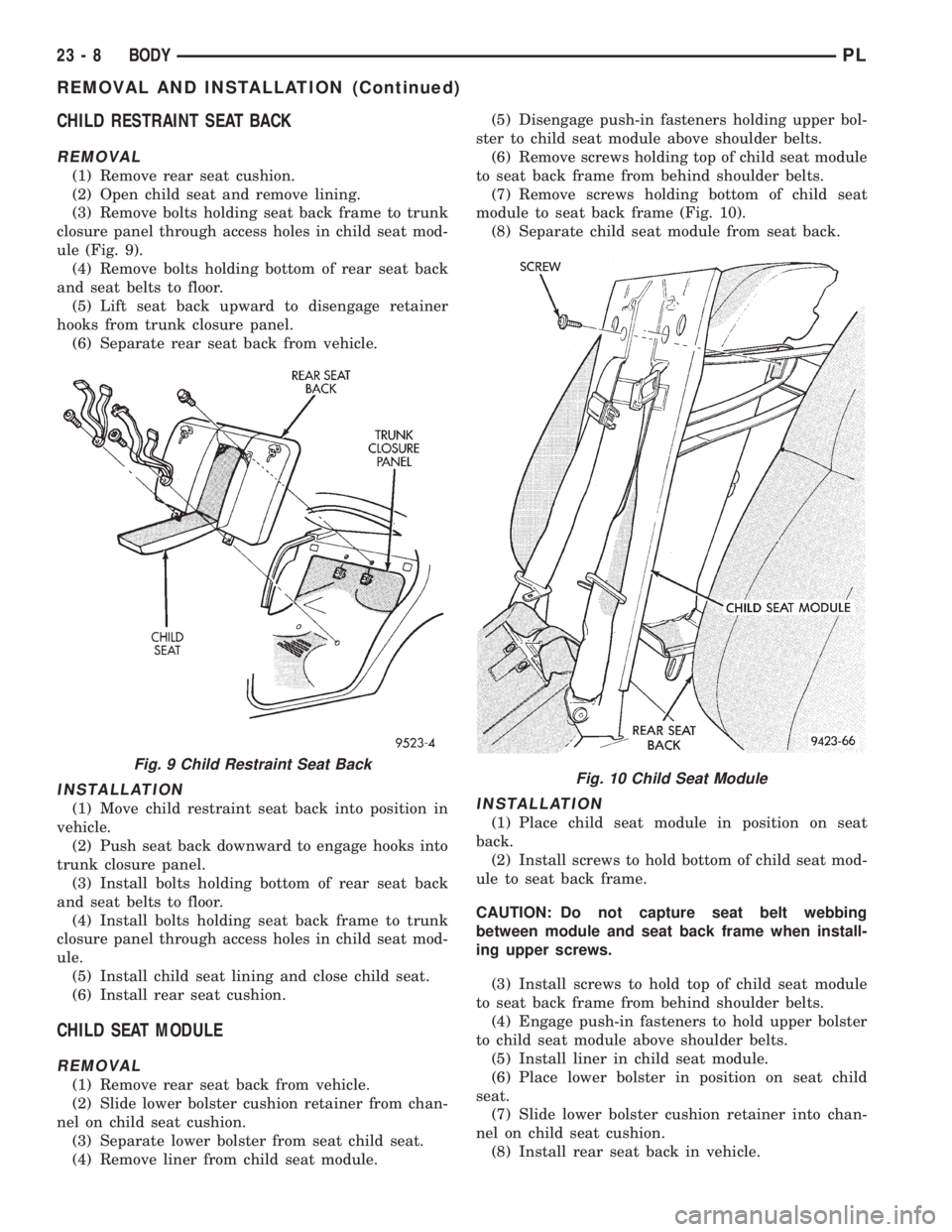

CHILD RESTRAINT SEAT BACK

REMOVAL

(1) Remove rear seat cushion.

(2) Open child seat and remove lining.

(3) Remove bolts holding seat back frame to trunk

closure panel through access holes in child seat mod-

ule (Fig. 9).

(4) Remove bolts holding bottom of rear seat back

and seat belts to floor.

(5) Lift seat back upward to disengage retainer

hooks from trunk closure panel.

(6) Separate rear seat back from vehicle.

INSTALLATION

(1) Move child restraint seat back into position in

vehicle.

(2) Push seat back downward to engage hooks into

trunk closure panel.

(3) Install bolts holding bottom of rear seat back

and seat belts to floor.

(4) Install bolts holding seat back frame to trunk

closure panel through access holes in child seat mod-

ule.

(5) Install child seat lining and close child seat.

(6) Install rear seat cushion.

CHILD SEAT MODULE

REMOVAL

(1) Remove rear seat back from vehicle.

(2) Slide lower bolster cushion retainer from chan-

nel on child seat cushion.

(3) Separate lower bolster from seat child seat.

(4) Remove liner from child seat module.(5) Disengage push-in fasteners holding upper bol-

ster to child seat module above shoulder belts.

(6) Remove screws holding top of child seat module

to seat back frame from behind shoulder belts.

(7) Remove screws holding bottom of child seat

module to seat back frame (Fig. 10).

(8) Separate child seat module from seat back.

INSTALLATION

(1) Place child seat module in position on seat

back.

(2) Install screws to hold bottom of child seat mod-

ule to seat back frame.

CAUTION: Do not capture seat belt webbing

between module and seat back frame when install-

ing upper screws.

(3) Install screws to hold top of child seat module

to seat back frame from behind shoulder belts.

(4) Engage push-in fasteners to hold upper bolster

to child seat module above shoulder belts.

(5) Install liner in child seat module.

(6) Place lower bolster in position on seat child

seat.

(7) Slide lower bolster cushion retainer into chan-

nel on child seat cushion.

(8) Install rear seat back in vehicle.

Fig. 9 Child Restraint Seat BackFig. 10 Child Seat Module

23 - 8 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1090 of 1200

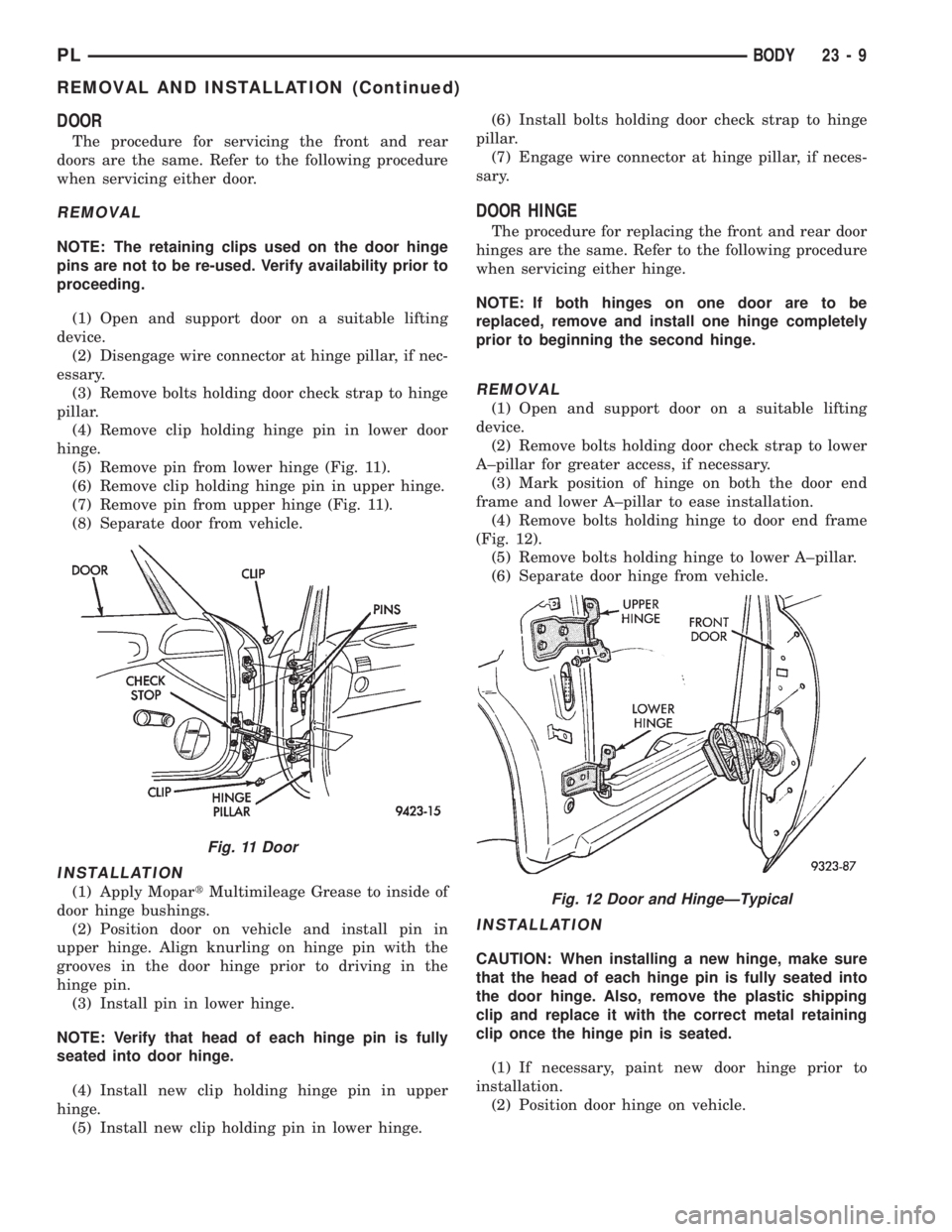

DOOR

The procedure for servicing the front and rear

doors are the same. Refer to the following procedure

when servicing either door.

REMOVAL

NOTE: The retaining clips used on the door hinge

pins are not to be re-used. Verify availability prior to

proceeding.

(1) Open and support door on a suitable lifting

device.

(2) Disengage wire connector at hinge pillar, if nec-

essary.

(3) Remove bolts holding door check strap to hinge

pillar.

(4) Remove clip holding hinge pin in lower door

hinge.

(5) Remove pin from lower hinge (Fig. 11).

(6) Remove clip holding hinge pin in upper hinge.

(7) Remove pin from upper hinge (Fig. 11).

(8) Separate door from vehicle.

INSTALLATION

(1) Apply MopartMultimileage Grease to inside of

door hinge bushings.

(2) Position door on vehicle and install pin in

upper hinge. Align knurling on hinge pin with the

grooves in the door hinge prior to driving in the

hinge pin.

(3) Install pin in lower hinge.

NOTE: Verify that head of each hinge pin is fully

seated into door hinge.

(4) Install new clip holding hinge pin in upper

hinge.

(5) Install new clip holding pin in lower hinge.(6) Install bolts holding door check strap to hinge

pillar.

(7) Engage wire connector at hinge pillar, if neces-

sary.

DOOR HINGE

The procedure for replacing the front and rear door

hinges are the same. Refer to the following procedure

when servicing either hinge.

NOTE: If both hinges on one door are to be

replaced, remove and install one hinge completely

prior to beginning the second hinge.

REMOVAL

(1) Open and support door on a suitable lifting

device.

(2) Remove bolts holding door check strap to lower

A±pillar for greater access, if necessary.

(3) Mark position of hinge on both the door end

frame and lower A±pillar to ease installation.

(4) Remove bolts holding hinge to door end frame

(Fig. 12).

(5) Remove bolts holding hinge to lower A±pillar.

(6) Separate door hinge from vehicle.

INSTALLATION

CAUTION: When installing a new hinge, make sure

that the head of each hinge pin is fully seated into

the door hinge. Also, remove the plastic shipping

clip and replace it with the correct metal retaining

clip once the hinge pin is seated.

(1) If necessary, paint new door hinge prior to

installation.

(2) Position door hinge on vehicle.

Fig. 11 Door

Fig. 12 Door and HingeÐTypical

PLBODY 23 - 9

REMOVAL AND INSTALLATION (Continued)